An energy-saving and environment-friendly bio-glue curtain cabinet and its waste gas waste treatment method

An energy-saving, environmentally friendly and bio-adhesive technology, applied in the field of water curtain cabinets, can solve problems such as difficulty in cleaning and inability to guarantee secondary pollution treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

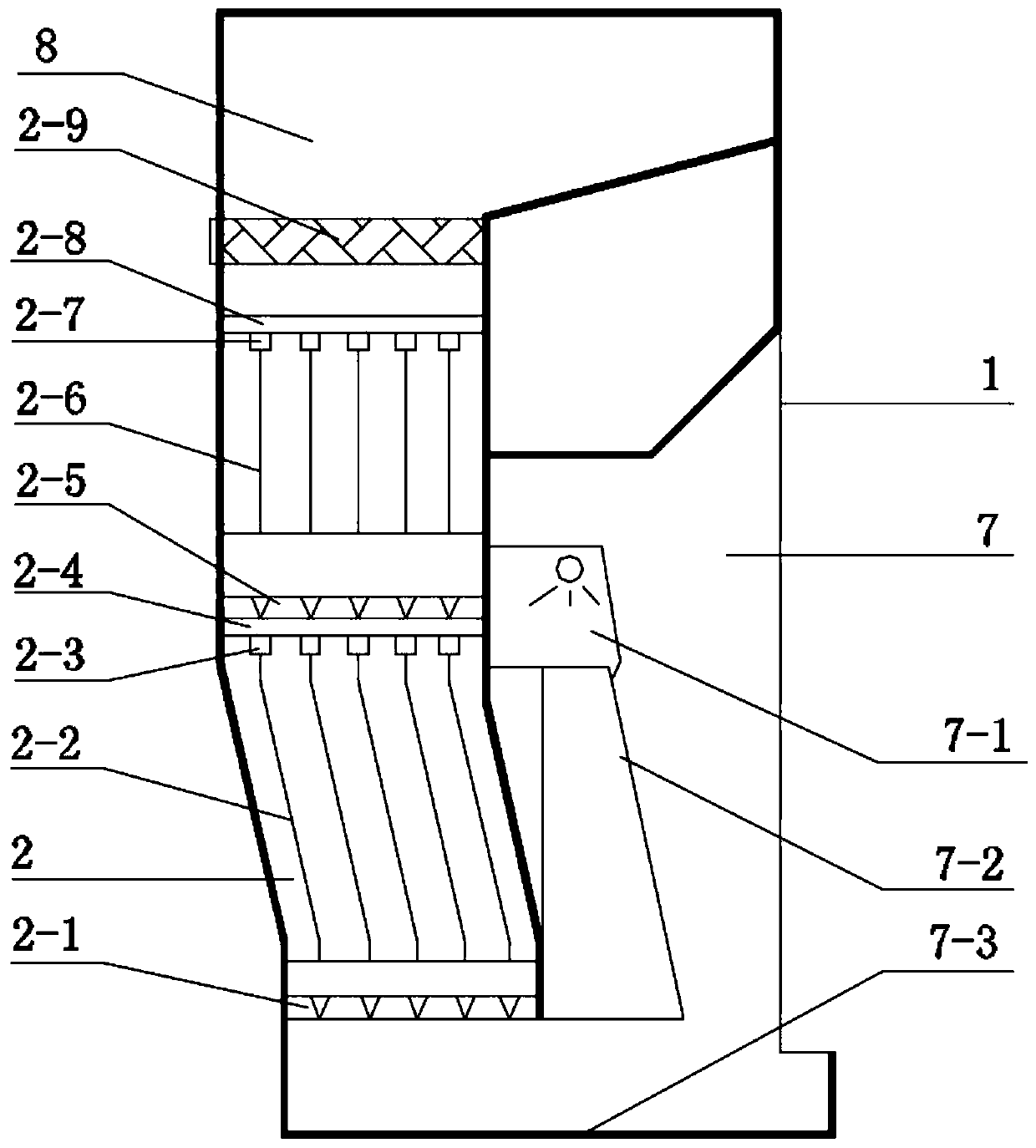

[0051] Embodiment 1: as Figure 4 As shown, when the front activated carbon adsorption purification chamber 10, the photolysis sterilization chamber 11, the rear activated carbon adsorption purification chamber 12, the muffler chamber 13 and the exhaust duct 14 are combined and arranged on the cabinet body 1, the front activated carbon adsorption purification chamber 10 It is arranged above the gas static pressure chamber 8 and communicates with the gas static pressure chamber 8. The photolysis sterilization chamber 11 is arranged above the front activated carbon adsorption purification chamber 10 and communicates with the front activated carbon adsorption purification chamber 10. The rear activated carbon adsorption purification chamber 12 It is arranged above the photolysis sterilization chamber 11 and communicates with the photolysis sterilization chamber 11. The anechoic chamber 13 is arranged above the rear activated carbon adsorption purification chamber 12 and communicat...

Embodiment 2

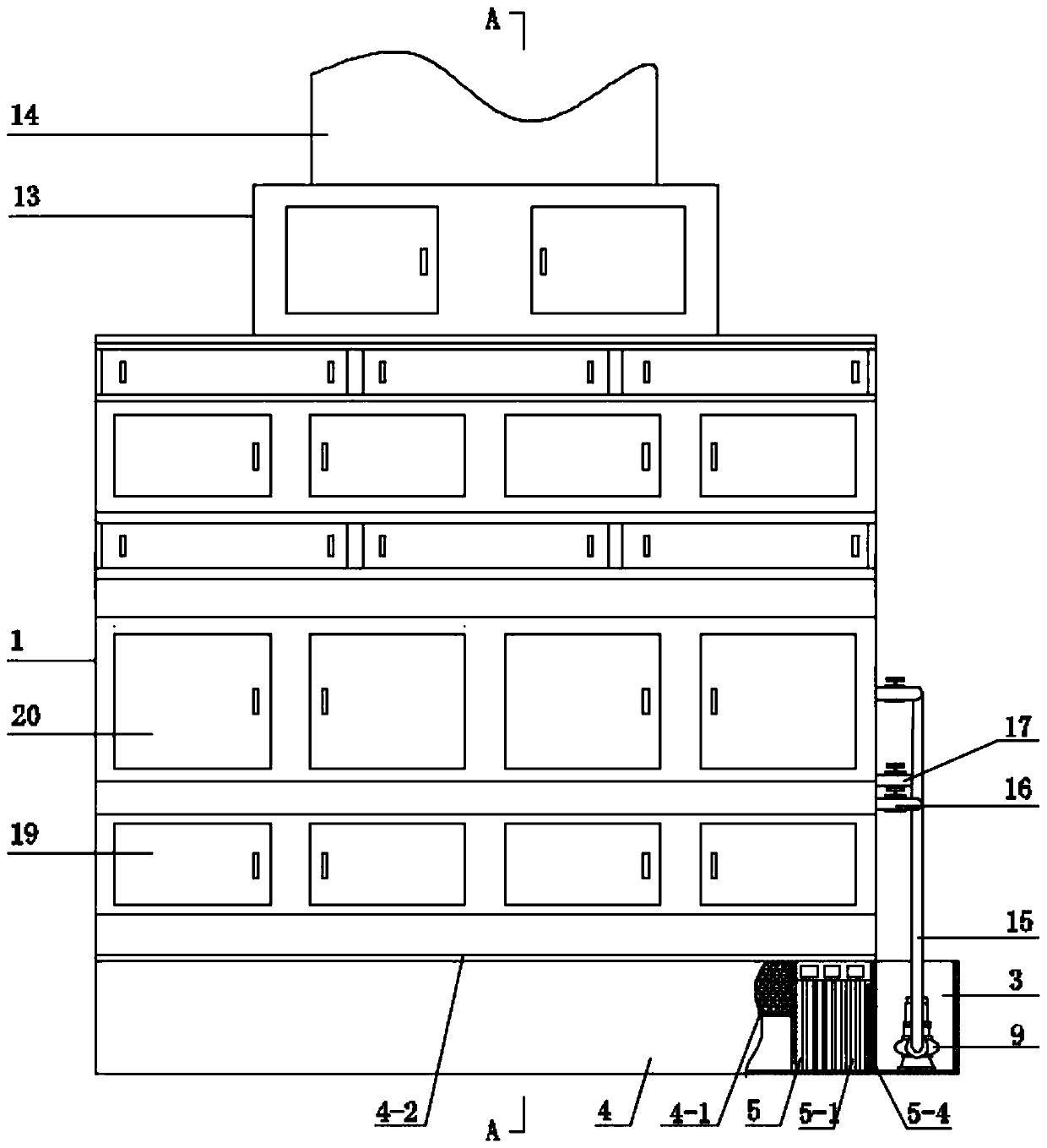

[0052] Embodiment 2: as Figure 5 As shown, when the front activated carbon adsorption purification chamber 10, the photolysis sterilization chamber 11, the rear activated carbon adsorption purification chamber 12, the muffler chamber 13 and the exhaust duct 14 are combined and arranged outside the cabinet body 1, the front activated carbon adsorption purification chamber 10 The first pipeline 21 communicates with the gas static pressure chamber 8, the photolysis sterilizing chamber 11 is arranged above the front activated carbon adsorption purification chamber 10 and communicates with the front activated carbon adsorption purification chamber 10, and the rear activated carbon adsorption purification chamber 12 is arranged on the photolysis chamber. Above the sterilizing chamber 11 and communicate with the photolysis sterilizing chamber 11, the anechoic chamber 13 is arranged above the rear activated carbon adsorption purification chamber 12 and communicates with the rear activ...

Embodiment 3

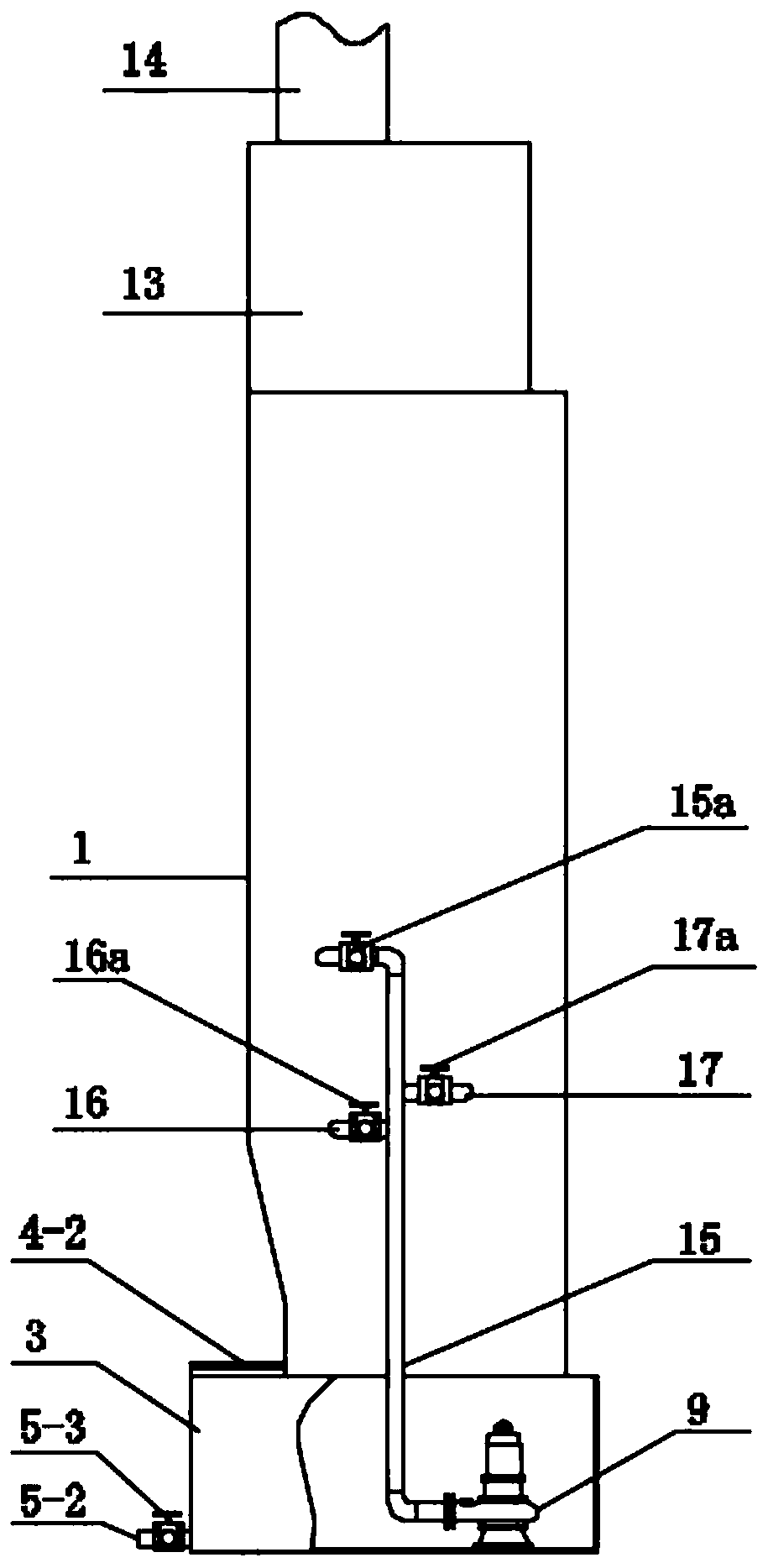

[0053] Embodiment 3: as Figure 6 As shown, when the front activated carbon adsorption purification chamber 10, the photolysis sterilization chamber 11, the rear activated carbon adsorption purification chamber 12, the muffler chamber 13 and the exhaust duct 14 are all independently arranged outside the cabinet body 1, the front activated carbon adsorption purification chamber 10 The second pipeline 22 communicates with the gas static pressure chamber 8, the photolysis sterilization chamber 11 communicates with the front active carbon adsorption purification chamber 10 through the third pipeline 23, and the rear activated carbon adsorption purification chamber 12 communicates with the photolysis sterilization chamber through the fourth pipeline 24. 11 communicates, the muffler chamber 13 communicates with the rear activated carbon adsorption purification chamber 12 through the fifth pipeline 25, and the exhaust duct 14 communicates with the muffler chamber 13.

[0054] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com