Electrolytic deburring device of air cylinder body

A technology for deburring and cylinder block, applied in the field of electrolytic deburring device for cylinder block, can solve the problems of weakened electrode rod strength, unusable use, low production efficiency, etc., and achieves the effect of compact structure, ideal effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

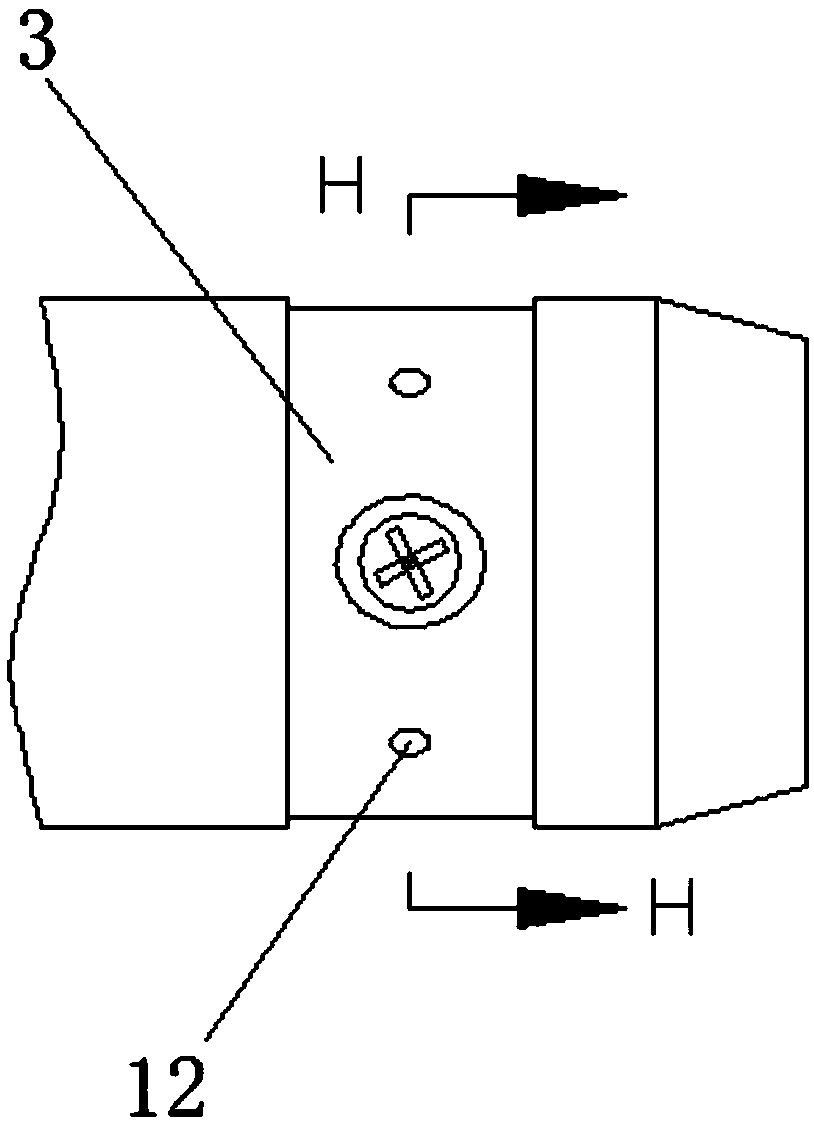

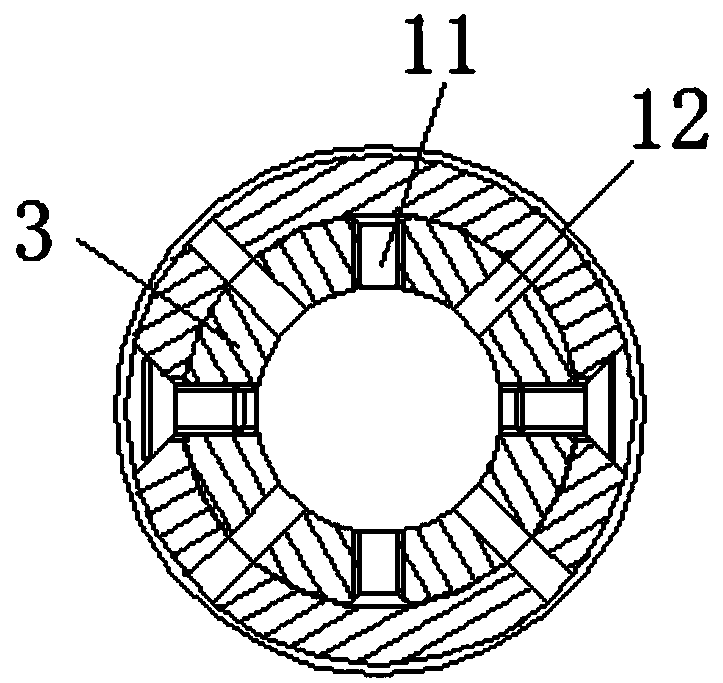

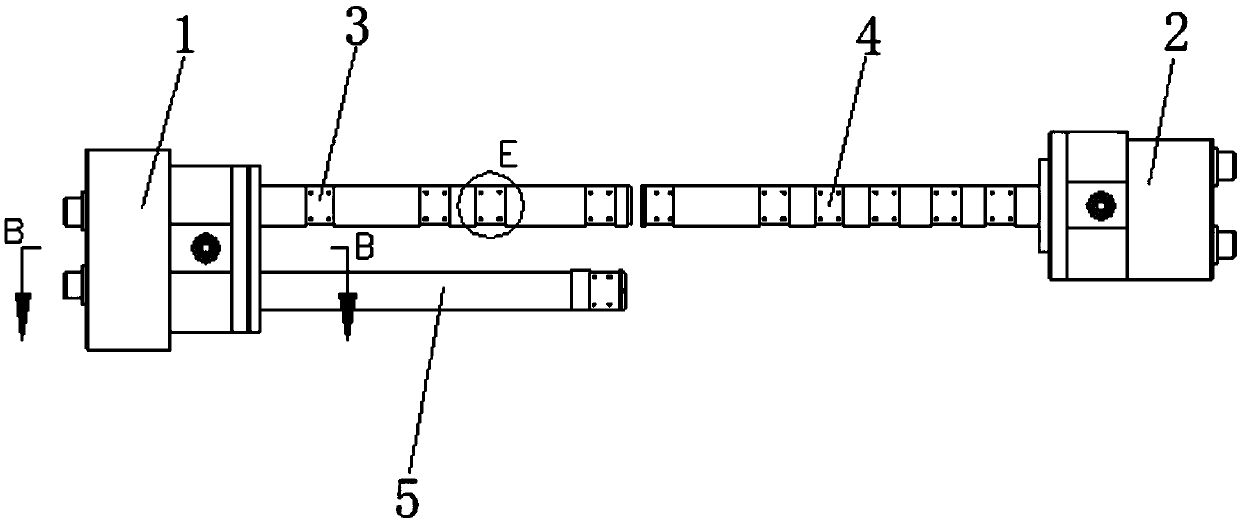

[0036] refer to Figure 3-13 As shown, a cylinder block electrolytic deburring device of the present invention includes an electrode left joint 1, an electrode right joint 2, a main oil passage left electrode 3, a main oil passage right electrode 4 and an auxiliary oil passage electrode 5, wherein the electrode left The joint 1 includes a panel 6 and a socket 7. The left electrode 3 of the main oil gallery and the electrode 5 of the auxiliary oil gallery are integrally installed on one side of the panel 6 through the socket 7. The panel 6 is provided with a first infusion hole 8, which The first infusion hole 8 is provided along the radial direction of the panel 6 and communicates with the outside world. The opening end of the infusion hole is provided with threads for easy connection of the electrolyte infusion hose. The hole 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com