foam plastic mold

A foamed plastic and mold technology, applied in the field of foamed plastic molds, can solve the problems of high production cost, mold heating, long production cycle time, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

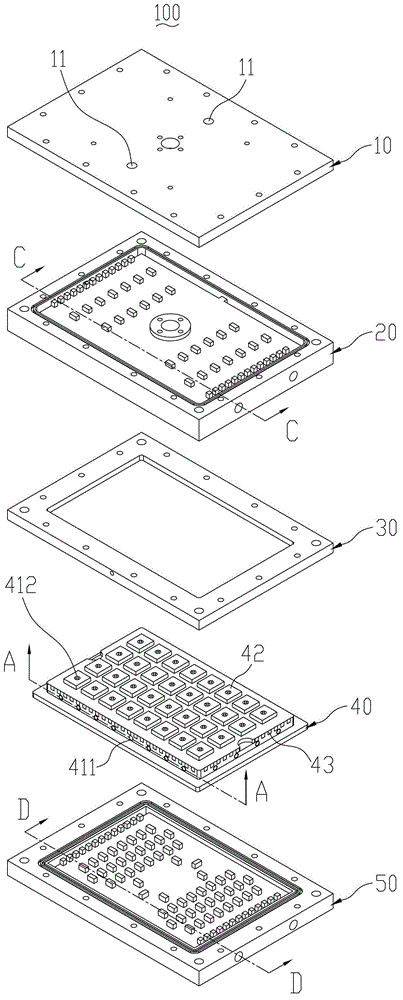

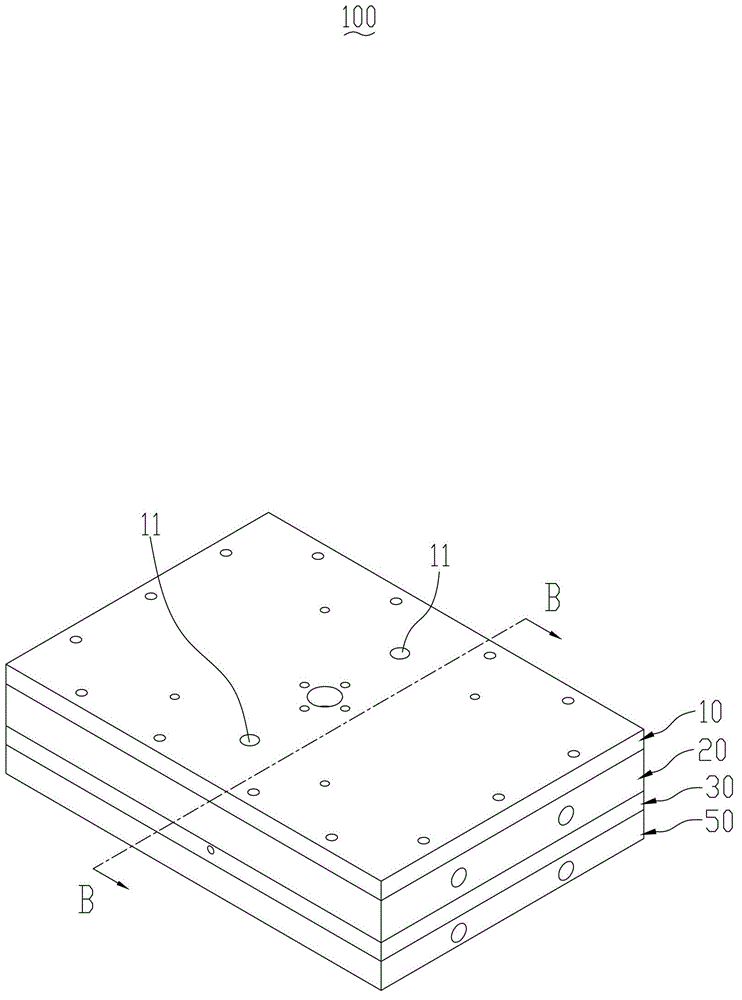

[0034] Please check figure 1 and figure 2 , a foam plastic mold 100 of the present invention is mainly used for producing foam boxes for placing electronic products. The mold 100 includes a top mold bottom plate 10, a top mold frame 20, a mold core cover 30, a mold core 40 and a bottom mold bottom plate 50 stacked together from top to bottom, and the mold core cover 30 sets Place around the core 40.

[0035] Two soda water inlets 11 are vertically penetrating through the upper die bottom plate 10 . The middle part of the bottom surface of the upper mold bottom plate 10 is provided with an annular waterproof wall 12 (such as Figure 9 shown).

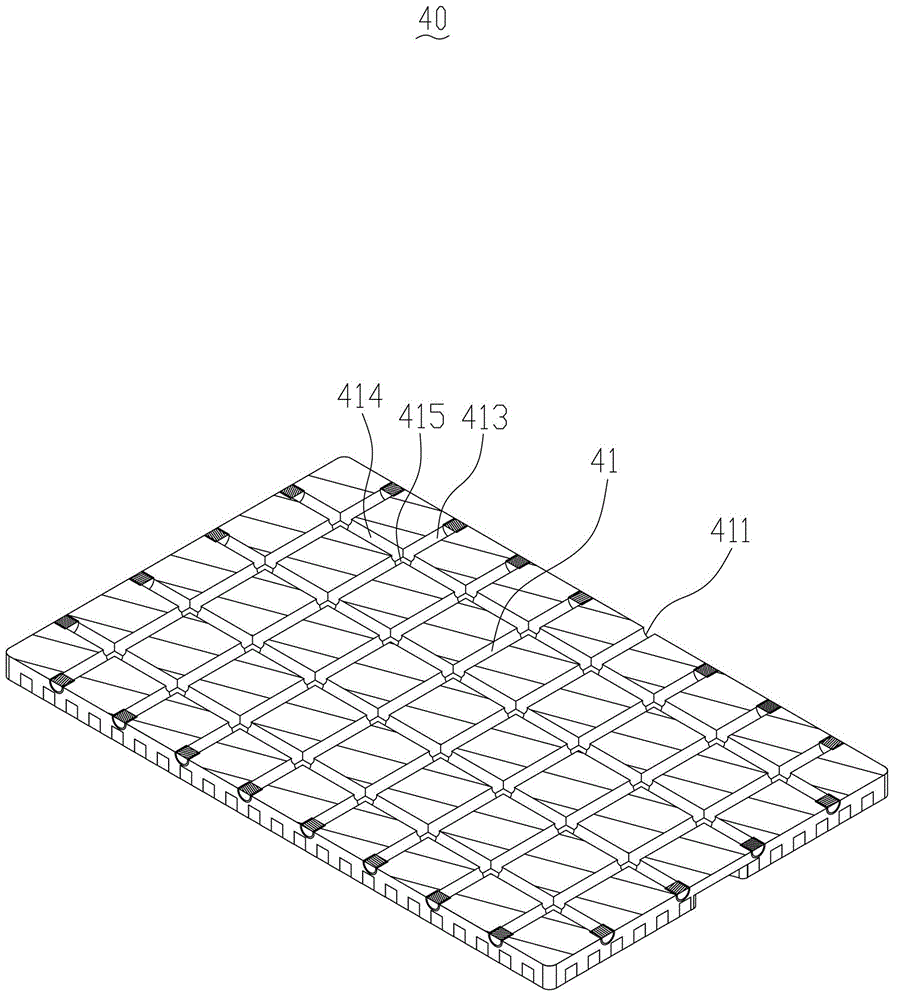

[0036] Please refer to figure 1 , image 3 and Figure 4 A plurality of core heads 42 protrude from the top surface of the core 40 . The shape of the core head 42 can be square or circular, and the specific shape depends on the product. A steam channel 41 is disposed inside the mold core 40 . The steam channel 41 includes a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com