Alignment-free Headphone cable extrusion mold system and manufacturing method of headphone cable extrusion mold system

A wire and centering technology, applied in the field of headphone wire centering-free extrusion mold system, can solve problems such as huge consumption of raw materials, and achieve the effects of stable product quality, uniform outer quilt and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

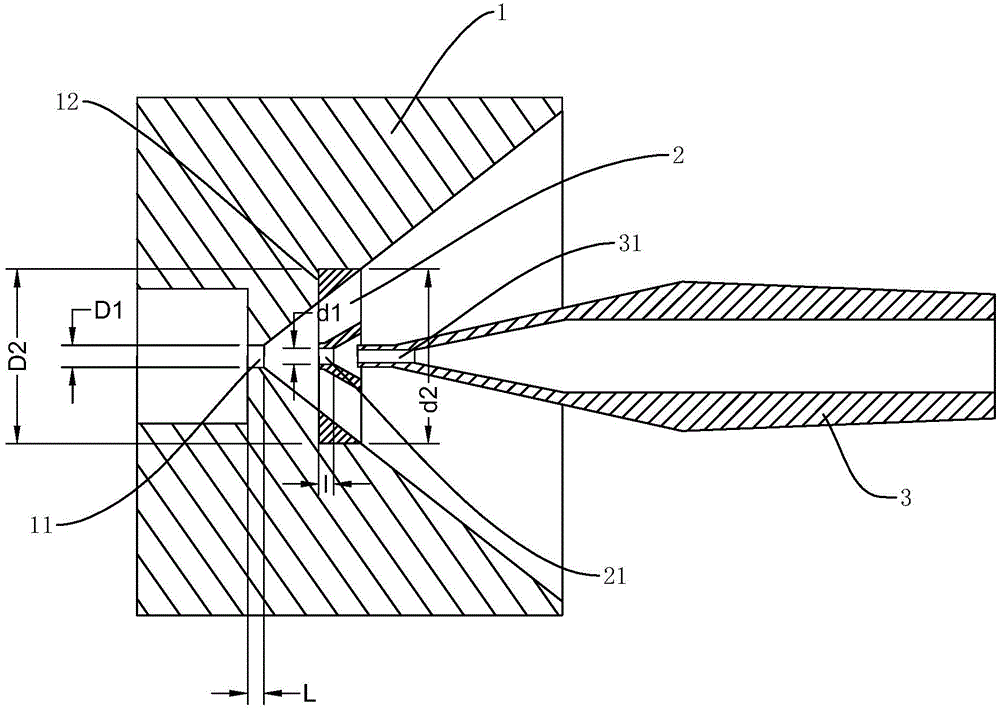

[0014] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, an alignment-free extrusion mold system for earphone wires includes a die 1 and a guide cone 3, and a mold core is arranged between the die 1 and the guide cone 3 2. The die 1 is provided with a die hole 11 for forming the wire core, the guide cone 3 is provided with a wire core hole 31 for wire core delivery, and the die core 2 is provided with a wire core hole 31 for wire The core is positioned to the core hole 21 in the center of the hole 11 .

[0015] A method for manufacturing an alignment-free extrusion mold system for earphone wires, comprising the following steps:

[0016] (1) To process the die 1, the same clamping is used to complete the processing of the die hole 11 and the core distribution groove 12 of the die 1 at one time;

[0017] (2) Process the mold core 2, adopt the same clamping, and complete the processing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com