Bulk material distributing device used for lime kiln

A technology of distributor and lime kiln, applied in the field of calcium hydroxide production equipment, can solve the problems of complex lime kiln device structure, uneven coal seam tightness, uneven ventilation, etc. Avoid the effect of partial under-burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

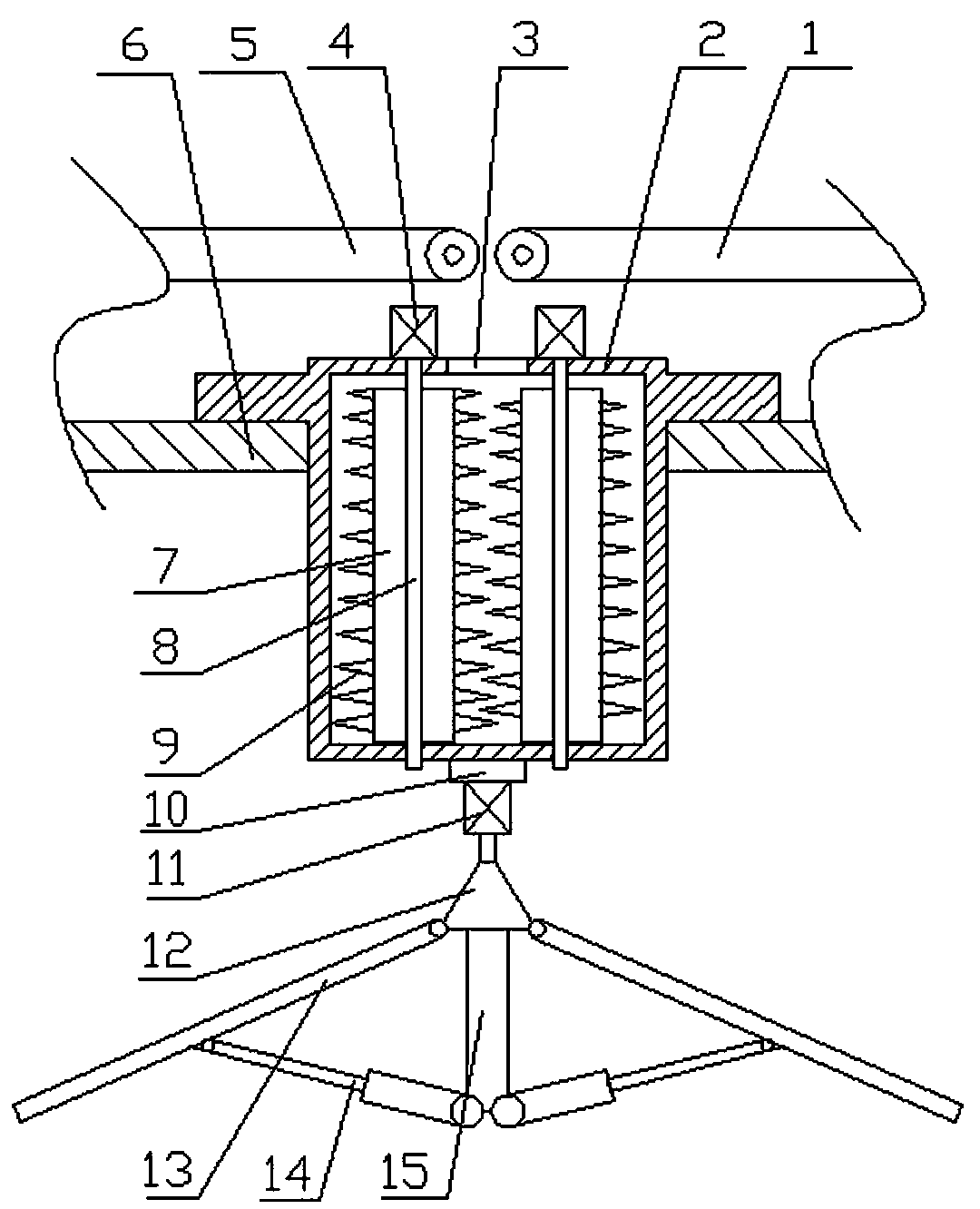

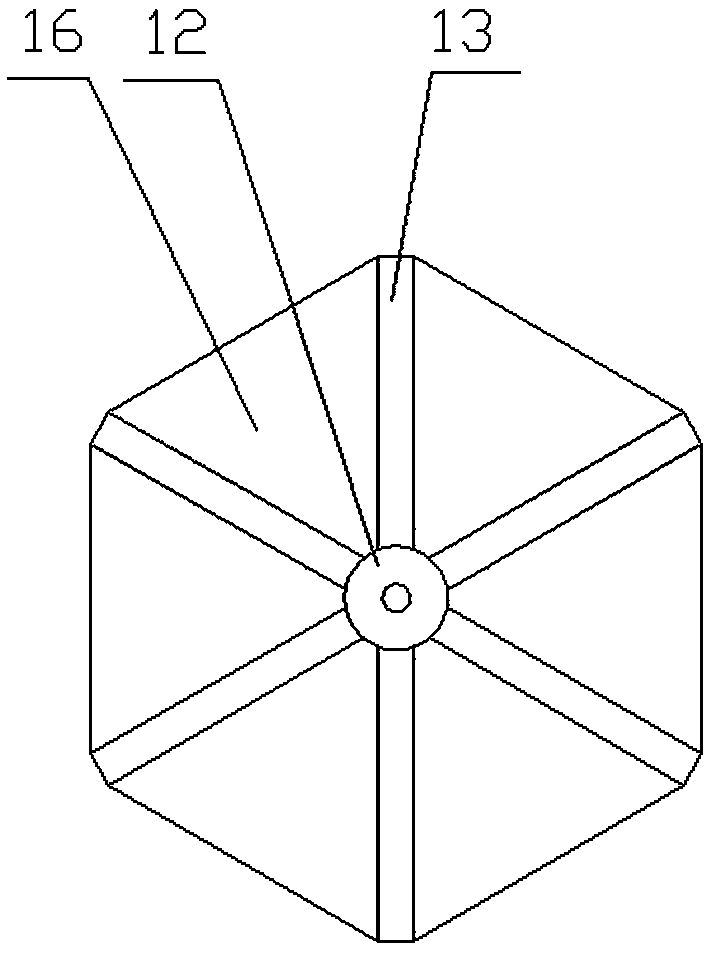

[0018] Such as figure 1 and figure 2 As shown, a bulk material distributor for a lime kiln 6 of the present invention includes a crushing barrel 2 fixed vertically in the opening of the top wall of the lime kiln 6, the crushing barrel 2 is cylindrical, and the inner cavity of the crushing barrel 2 There is a crushing mechanism in the middle, which is used to break the agglomerated coal, so that the coal can be burned evenly and the limestone can be heated evenly. At the same time, the crushing mechanism in the crushing bucket 2 also has a certain stirring function, which is beneficial to further uniform mixing of limestone and coal particles. In this embodiment, a flange is fixed on the middle and upper part of the outer wall of the crushing barrel 2, and the crushing barrel 2 is fixed on the outside of the top wall of the lime kiln 6 through flanges and bolts.

[0019] The center position of the upper end of the crushing barrel 2 is provided with a feeding port 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com