Inner and outer synchronously cured double-component organic silicon pouring sealant and preparation method thereof

A silicone potting glue, two-component technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor bonding effect, unstable system, etc., and meet the bonding needs , Improve leveling and promote wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

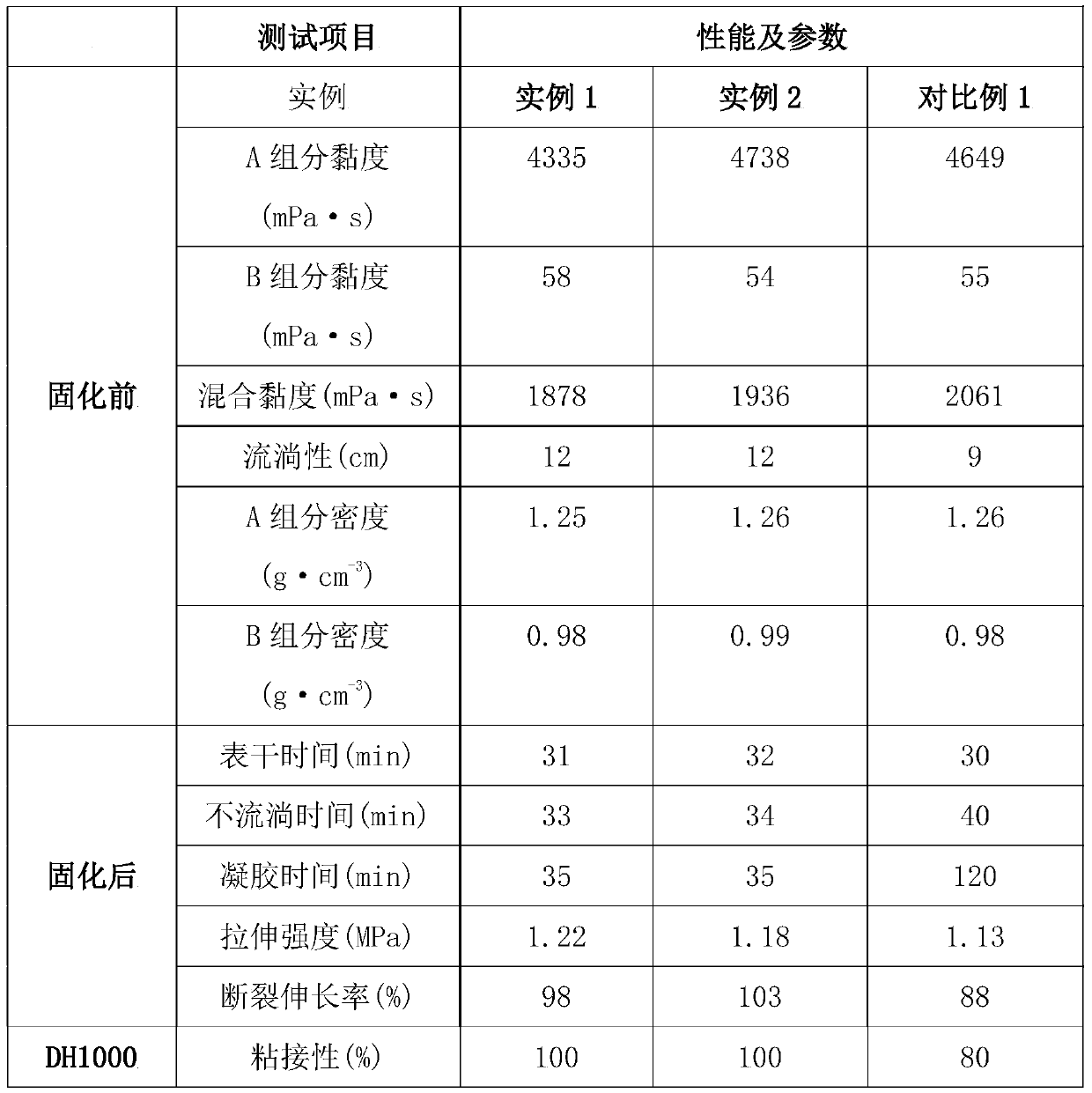

Embodiment 1

[0021] At room temperature, 50 parts of 2000mPa·s α,ω-dihydroxy polydimethylsiloxane, 45 parts of aluminum hydroxide, 40 parts of aluminum oxide, 3 parts of titanium dioxide and 8 parts of methyl ethoxy were mixed and capped Add silicone oil into a 1000L high-speed stirring tank, stir in vacuum for 2 hours, the vacuum degree is -0.95MPa, then add 50 parts of 1000mPa·s α,ω-dihydroxy polydimethylsiloxane, 0.5 weight percent concentration after cooling to room temperature 85% methanol solution of silicone-modified thioether, mixed and stirred at high speed for 0.5h, and then vacuum defoamed to obtain component A; Parts of aminosilane oligomers were pre-reacted at 100°C for 1 hour, and after cooling to room temperature, 30 parts of polyethyl silicate, 20 parts of dimethyldiethoxysilane, 5 parts of KH-792 and 0.08 parts of dilaurel Add dioctyltin acid into the reactor, stir and mix under vacuum for 0.5h to obtain component B; mix the obtained component A and component B at a weight...

Embodiment 2

[0023] At room temperature, 50 parts of 1500mPa·s α,ω-dihydroxy polydimethylsiloxane, 40 parts of aluminum hydroxide, 40 parts of silicon micropowder, 5 parts of titanium dioxide and 10 parts of 350mPa·s dimethyl silicone oil Add it into a 1000L high-speed stirred tank, stir in vacuum for 2 hours, and the vacuum degree is -0.95MPa, then add 50 parts of 1500mPa·s α,ω-dihydroxy polydimethylsiloxane after cooling to room temperature, 1.5 parts by weight with a concentration of 75% methanol solution of silicone-modified thioether, mixed and stirred at high speed for 0.5h, and then vacuum degassed to obtain component A; 100 parts of silane-modified polyether resin with a viscosity of 600mPa·s, 7.5 parts of aminosilane oligomer in Pre-react at a temperature of 100°C for 0.5h, and after cooling to room temperature, mix 20 parts of tetraethoxysilane, 10 parts of methyltrimethoxysilane, 20 parts of dimethyldiethoxysilane, 7.5 parts of KH-540 and 0.05 Add two parts of dibutyltin dilaura...

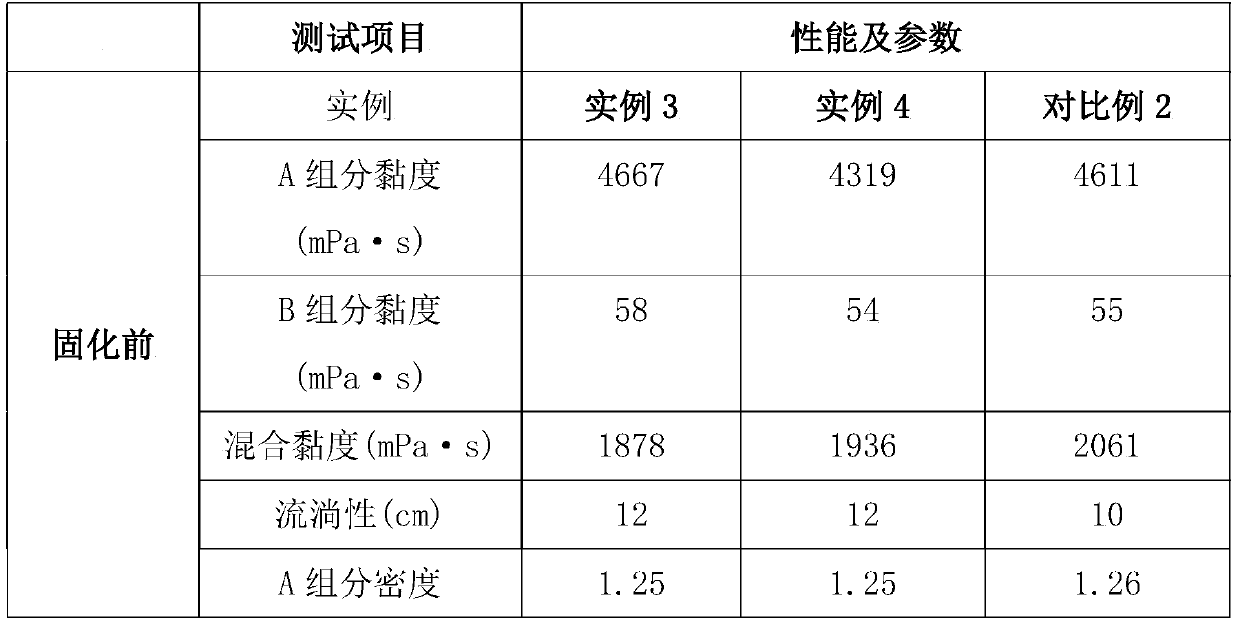

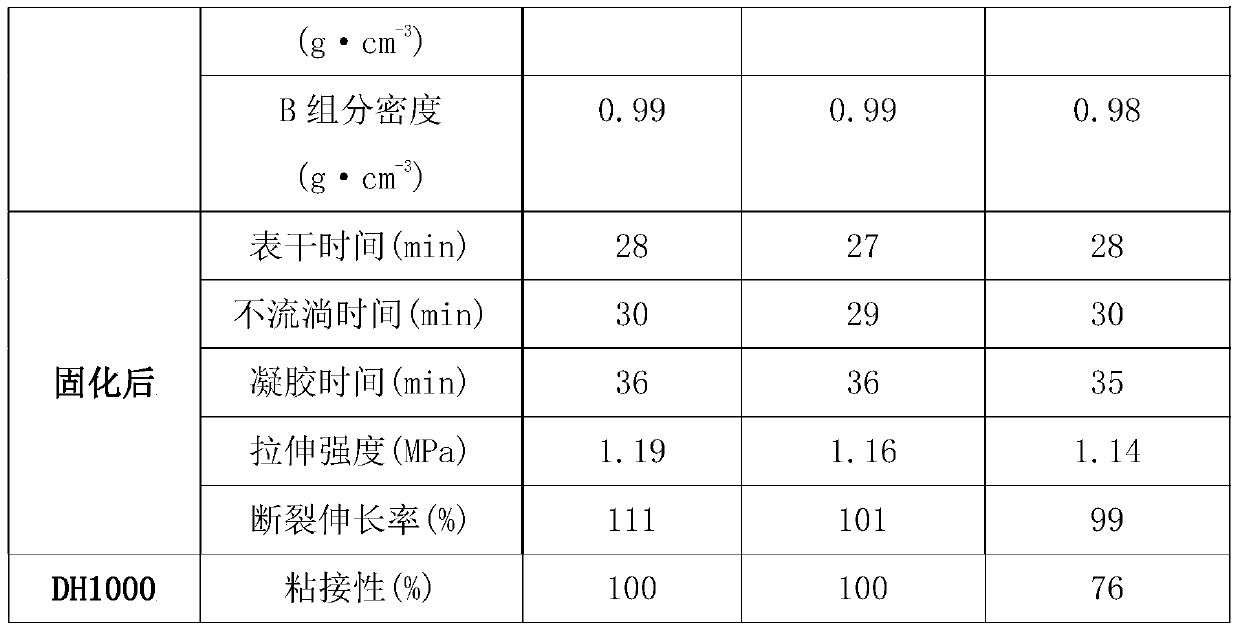

Embodiment 3

[0029] Add 50 parts of 1500mPa·s α,ω-dihydroxy polydimethylsiloxane, 40 parts of light calcium carbonate, 30 parts of aluminum oxide and 1 part of hydroxyl silicone oil into a 1000L high-speed stirring tank at room temperature, and stir under vacuum for 1.5 h, the vacuum degree is -0.95MPa, then after cooling to room temperature, add 50 parts of α, ω-dihydroxypolydimethylsiloxane of 1500mPa·s, 2 parts by weight of 90% silicone modified sulfide Ethanol solution, mixed and stirred at high speed for 0.5h, and then vacuum degassed to obtain component A; 100 parts of silane-modified polyurethane resin with a viscosity of 800mPa·s and 5 parts of aminosilane oligomer were pre-reacted at 100°C for 0.5h, After cooling to room temperature, add 25 parts of polyethylsilicate, 15 parts of dimethyldiethoxysilane, 5 parts of KH-792 and 0.1 part of dioctyltin dicaprate into the reactor, and stir and mix under vacuum for 0.5h Obtain component B; mix the obtained component A and component B at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com