High weather resistant polyurethane adhesive

A polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor adhesion, limited weather resistance, and long curing cycle of silicone rubber. Achieve the effect of breaking the poor weather resistance, good weather resistance and high reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The A component consists of the following raw materials in parts by mass:

[0037] Polyurethane prepolymer: 70 parts;

[0038] YS-B09S-1050D: 30 copies;

[0039] The B component consists of the following raw materials in parts by mass:

[0040] Sovermol1092: 20 parts;

[0041] AF4330: 5;

[0042] The polyester diol of bulky side chain modification: 20 parts;

[0043] A-Link599: 1 copy;

[0044] 8184: 20 copies;

[0045] D405; 25 parts

[0046] Polycarbodiimide: 5 parts;

[0047] R202: 4 copies;

[0048] BiCAT8118: 0.1 part

[0049] (1) Preparation of polyurethane prepolymer: in parts by mass: Add 45.2 parts of 3190 produced by Croda into the reactor, dehydrate for 2.5 hours at 120°C and a vacuum of 0.08~0.1MPa, and cool down to After 60°C, add 54.8 parts of diphenylmethane diisocyanate into the reactor, then raise the temperature to 80°C to react until the mass percentage of -NCO ions is 14%, and obtain a polyurethane prepolymer;

[0050] (2) Preparation of c...

Embodiment 2

[0055] The A component consists of the following raw materials in parts by mass:

[0056] Polyurethane prepolymer: 80 parts;

[0057] YS-B09S-1050D: 20 copies;

[0058] The B component consists of the following raw materials in parts by mass:

[0059] Sovermol815: 22 parts;

[0060] P202: 20 copies;

[0061] XCP-488: 15 copies;

[0062] Sliquest*15744: 0.5 copies;

[0063] YS-B09S-1050D: 17 copies;

[0064] T805; 20 parts

[0065] Polycarbodiimide: 3 parts;

[0066] R202: 2.5 parts;

[0067] BiCAT8: 0.05 copies

[0068](1) Preparation of polyurethane prepolymer: in parts by mass: Add 45.2 parts of 3190 produced by Croda into the reactor, dehydrate for 2.5 hours at 120°C and a vacuum of 0.08~0.1MPa, and cool down to After 60°C, add 54.8 parts of diphenylmethane diisocyanate into the reactor, then raise the temperature to 80°C to react until the mass percentage of -NCO ions is 14%, and obtain a polyurethane prepolymer;

[0069] (2) Preparation of component A: Take 80 ...

Embodiment 3

[0074] The A component consists of the following raw materials in parts by mass:

[0075] Polyurethane prepolymer: 73 parts;

[0076] YS-B09S-1050D: 27 copies;

[0077] The B component consists of the following raw materials in parts by mass:

[0078] Sovermol1092: 17 parts;

[0079] AP11: 13 copies;

[0080] Sovermol815: 6 parts;

[0081] XCP-488: 18 copies;

[0082] Sliquest*15744: 1 copy;

[0083] YS-B09S-1050D: 17 copies;

[0084] T805; 20 parts

[0085] Polycarbodiimide: 4 parts;

[0086] R202: 3 copies;

[0087] BiCATZ: 0.05 copies

[0088] BiCAT8: 0.05 copies

[0089] (1) Preparation of polyurethane prepolymer: in parts by mass: Add 45.2 parts of 3190 produced by Croda into the reactor, dehydrate for 2.5 hours at 120°C and a vacuum of 0.08~0.1MPa, and cool down to After 60°C, add 54.8 parts of diphenylmethane diisocyanate into the reactor, then raise the temperature to 80°C to react until the mass percentage of -NCO ions is 14%, and obtain a polyurethane pre...

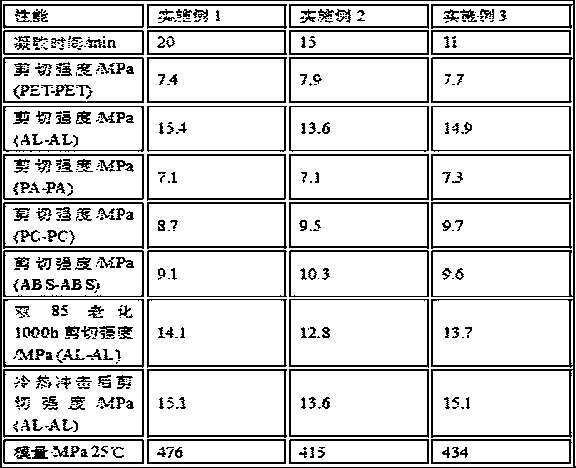

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com