A kind of room temperature curing instantaneous high temperature resistant high flexibility epoxy adhesive and preparation method thereof

An epoxy adhesive, room temperature curing technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of difficult to withstand instantaneous high temperature, poor flexibility of room temperature curing epoxy resin, etc., to improve heat resistance , Improve flexibility and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

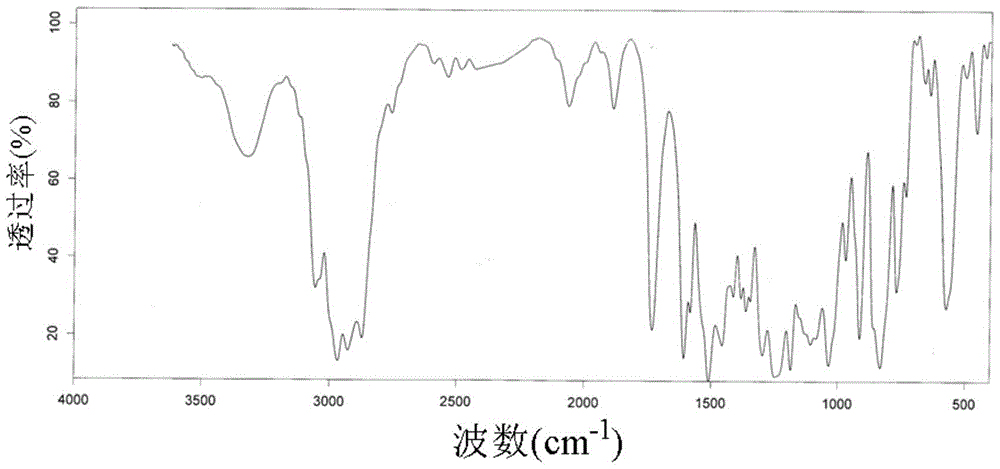

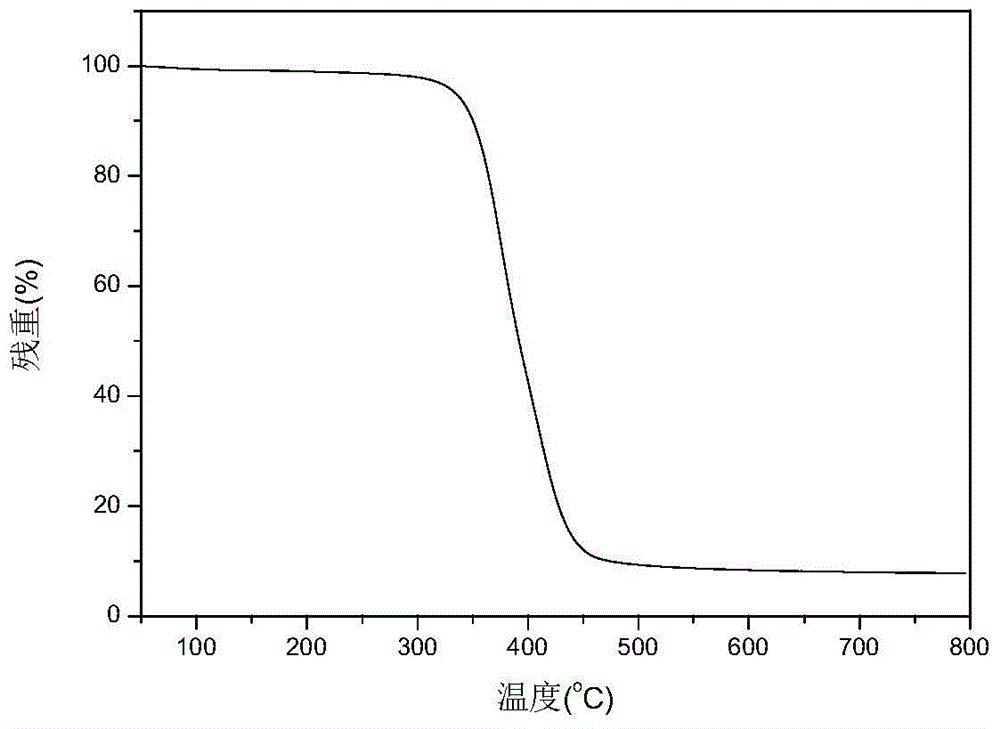

Image

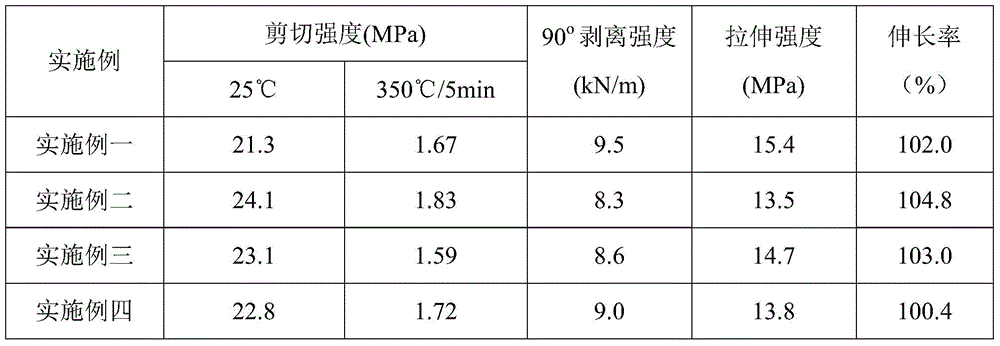

Examples

specific Embodiment approach 1

[0042] Specific implementation mode one: This implementation mode is a kind of room temperature curing instantaneous high temperature resistant high flexible epoxy adhesive consisting of 50-100 parts by weight of polyether modified epoxy resin, 60-120 parts of flexible curing agent, 10-100 parts by weight. It is prepared by 30 parts of boron phenolic resin, 1-3 parts of accelerator and 1-3 parts of coupling agent.

[0043] The principle of this implementation mode:

[0044] In this embodiment, the flexibility of the epoxy resin matrix is improved by modifying the epoxy resin with polyether; at the same time, the polyether amine and the polyamide are linked together by using the multifunctional epoxy resin to prepare a flexible curing agent; The obtained flexible curing agent cures the polyether modified epoxy resin, and the room temperature curing high flexible epoxy adhesive can be prepared; the multifunctional epoxy resin is provided in the room temperature curing transient ...

specific Embodiment approach 2

[0051] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the accelerator is DMP-30, 2-methylimidazole, triethanolamine, resorcinol or 2-ethyl-4-methyl imidazole. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the coupling agent is γ-glycidyl etheroxypropyl trimethoxysilane, isopropyl tri(dioctyl coke One or more mixtures of phosphate acyloxy) titanate, monoalkoxy unsaturated fatty acid titanate and bis(dioctyloxypyrophosphate) ethylene titanate. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com