Fast-curing high-strength epoxy adhesive

An epoxy adhesive, fast curing technology, applied in the direction of polymer adhesive additives, adhesive types, adhesives, etc. The problem of poor bonding strength, etc., can meet the needs of bonding, realize the requirements of rapid installation and maintenance, and improve the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A fast-curing high-strength epoxy adhesive, comprising A component and B component, the A component includes the following components by weight: 60-100 parts of epoxy resin, 1-10 parts of epoxy diluent parts, 30-60 parts of toughening composition, 5-50 parts of filler and 1-5 parts of thixotropic agent; said B component includes the following components by weight parts: 30-70 parts of amine curing agent, curing accelerator 1-20 parts of agent, 1-20 parts of filler and 1-5 parts of thixotropic agent.

[0040]Wherein, the above-mentioned toughening composition is a composition of a closed polyurethane prepolymer and a core-shell rubber dispersion, and the weight ratio of the two is 1:3-3:1.

[0041] Wherein, the above-mentioned blocked polyurethane prepolymer is obtained by reacting polyether polyol with excess isocyanate, and then blocking isocyanate with phenols.

[0042] Among them, the above polyether polyol is a polymer or copolymer of one or more of polyoxypropylen...

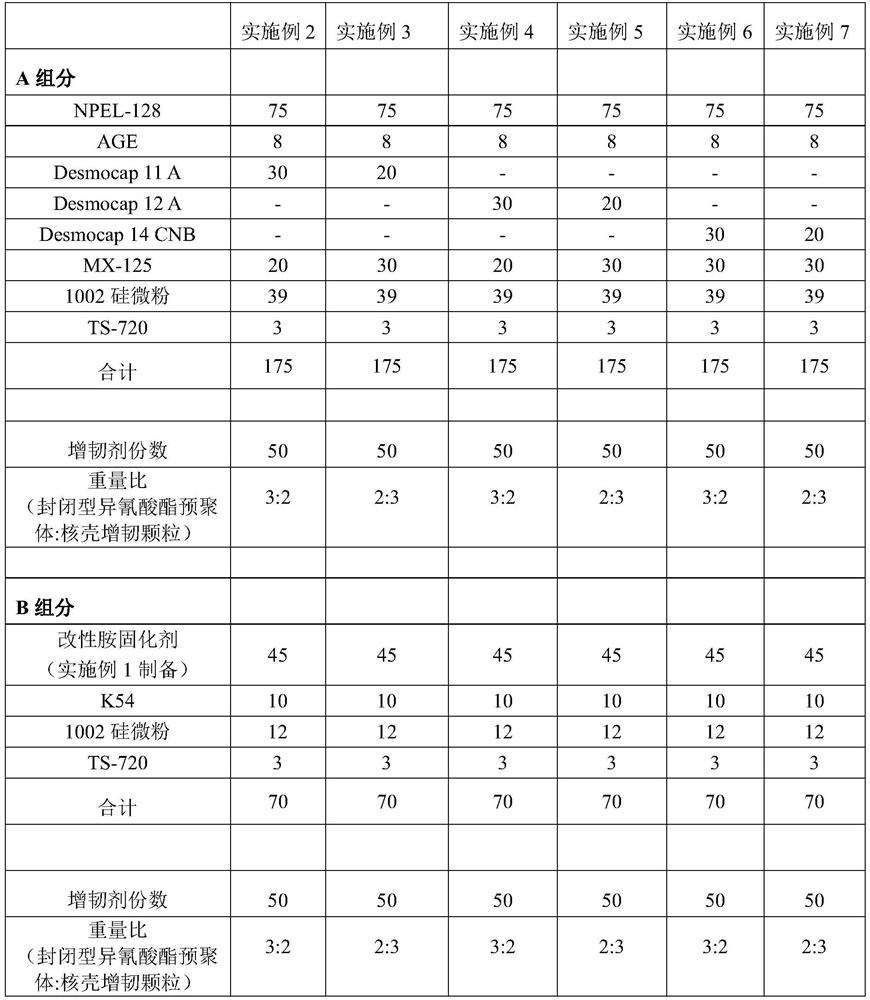

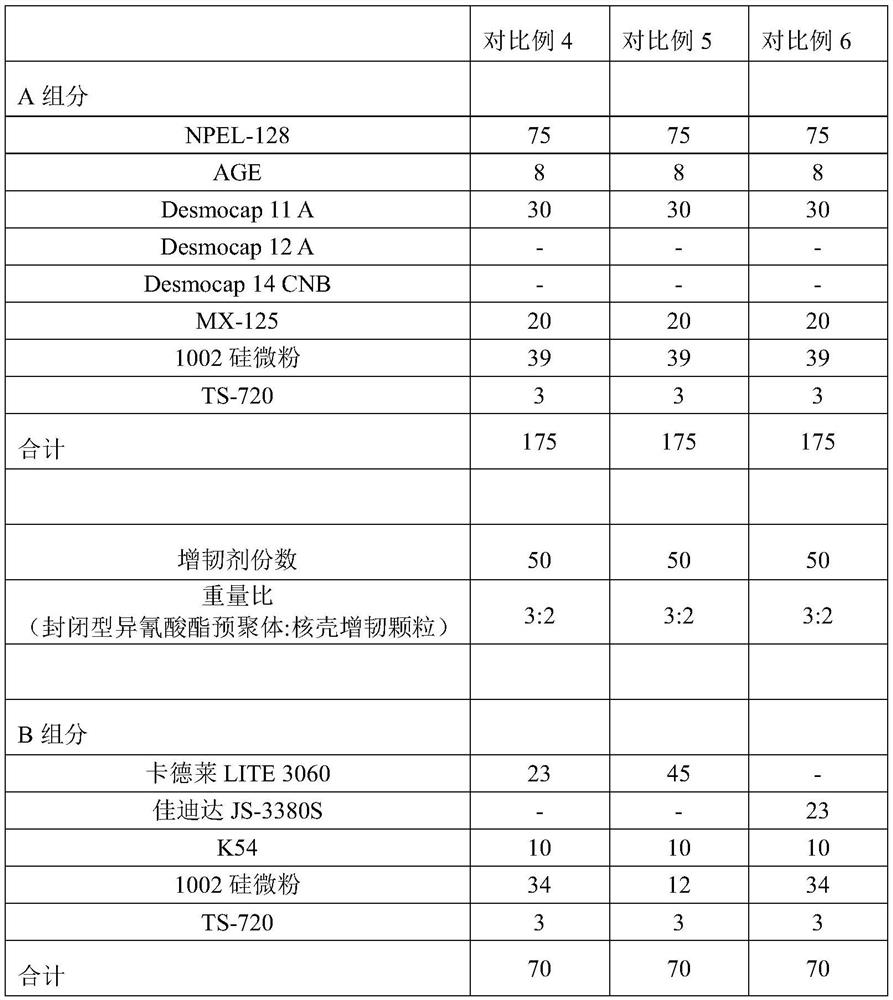

Embodiment 2- Embodiment 7

[0054] According to the A component and the B component provided in Example 1, the components of the high-strength epoxy adhesive are proportioned, wherein the epoxy resin is preferably bisphenol A type epoxy resin NPEL-128;

[0055] The epoxy diluent is C12-14 alkyl glycidyl ether (AGE);

[0056] The closed polyurethane prepolymer adopts the closed polyurethane prepolymer of Desmocap11A, Desmocap12A and Desmocap14CNB models;

[0057] The model of the core-shell rubber particle dispersion is MX125;

[0058] The filler is 1002 silica powder, the thixotropic agent is fumed silica, and the model is TS-720;

[0059] The curing accelerator is 2,4,6-tris(dimethylaminomethyl)phenol, K54.

[0060] The specific component ratio of the high-strength epoxy adhesive of embodiment 2-embodiment 7 is as follows:

[0061]

[0062] The preparation method of the high-strength epoxy adhesive of above-mentioned embodiment 2-embodiment 7 is:

[0063] The preparation method of component A: ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com