Organic silicon prepolymer, organic silicon modified epoxy resin, adhesive, colloid and preparation method thereof

An epoxy adhesive and epoxy resin technology, applied in the field of materials, can solve the problems of reduced bonding strength and inability to meet the bonding requirements of heating devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] The present invention also provides a kind of preparation method of silicone modified epoxy adhesive, comprising the following steps:

[0107] S101: preparing component A of the silicone-modified epoxy adhesive;

[0108] Further, step S101 includes the following steps:

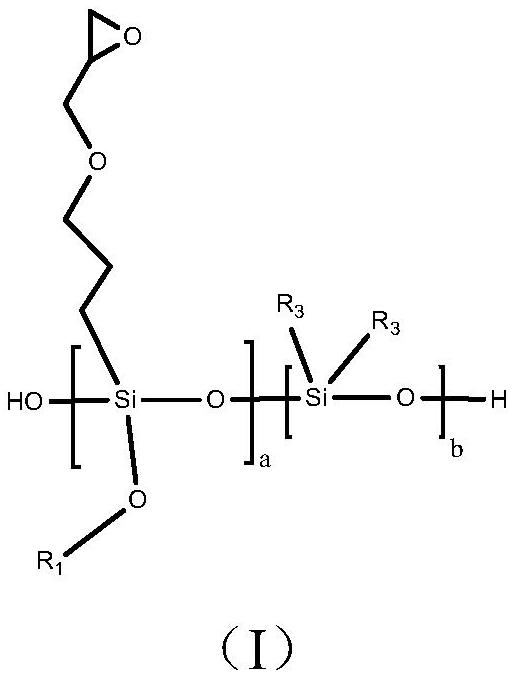

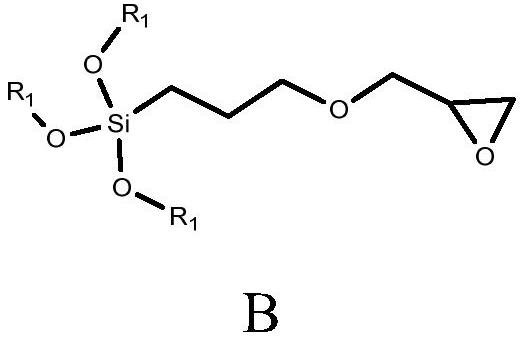

[0109] S1011: Mix siloxane, silicone oil, catalyst and water, and react at 110°C-130°C (preferably 115°C-125°C, more preferably 120°C) (preferably react for 1-3h, more preferably react 1.5-2.5h), to obtain silicone prepolymer.

[0110] The siloxane, silicone oil and catalyst in step S1011 are as above.

[0111] In one embodiment, step S1011 performs the following reaction:

[0112]

[0113] The definitions of each group in the above reaction formula are as described above.

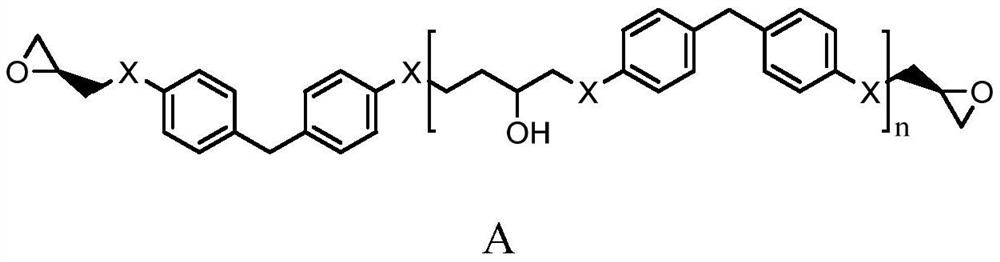

[0114] S1012: Mix the silicone prepolymer and epoxy resin, and react under the conditions of 110°C-130°C (preferably 115°C-125°C, more preferably 120°C) to obtain silicone-modified epoxy resin A component.

[0115] In one e...

Embodiment 1

[0132] Silicone modified epoxy adhesive

[0133] A component: silicone modified epoxy resin, its reaction raw materials: 40 parts of epoxy resin, 10 parts of siloxane, 10 parts of silicone oil, 1 part of 35% hydrochloric acid, 5 parts of deionized water;

[0134] Component B: 10 parts of 1,3-cyclohexanedimethylamine, 1 part of accelerator.

[0135] Preparation:

[0136] (1) Mix siloxane, silicone oil, catalyst and water, stir evenly, heat to 120°C at the same time, stir and reflux for 2 hours to obtain prepolymer a, set aside;

[0137] (2) Mix the epoxy resin with the prepolymer a obtained in step (1), stir, mix evenly, and heat to 120°C at the same time, stir and reflux for 2 hours, then open to stir and keep warm for 3 hours to obtain organic Silicon modified epoxy resin, as A component;

[0138] (3) Mix component A and component B at a mass ratio of 10:1 and stir evenly to prepare a mixture.

[0139] (4) Coating the mixture obtained in step (3) on the substrate and curi...

Embodiment 2

[0141] Silicone modified epoxy adhesive

[0142] A component: silicone modified epoxy resin, its reaction raw materials: 40 parts of epoxy resin, 5 parts of siloxane, 15 parts of silicone oil, 1 part of 35% hydrochloric acid, 5 parts of deionized water;

[0143] Component B: 10 parts of 1,3-cyclohexanedimethylamine, 1 part of accelerator.

[0144] Preparation:

[0145] (1) Mix siloxane, silicone oil, catalyst and water, stir evenly, heat to 120°C at the same time, stir and reflux for 2 hours to obtain prepolymer a, set aside;

[0146] (2) Mix the epoxy resin with the prepolymer a obtained in step (1), stir, mix evenly, and heat to 120°C at the same time, stir and reflux for 2 hours, then open to stir and keep warm for 3 hours to obtain organic Silicon modified epoxy resin, as A component;

[0147] (3) Mix component A and component B at a mass ratio of 10:1 and stir evenly to prepare a mixture.

[0148] (4) Coating the mixture obtained in step (3) on the substrate and curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com