Automatic tensile force detection device of wrapping machine

An automatic detection device and wrapping machine technology, applied in the direction of tension measurement, conductor/cable insulation, electrical components, etc., can solve the problems of wrapping tape rework, wrapping tape tension without measurement and monitoring, etc., to achieve reasonable structure and good detection results Accurate, timely and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

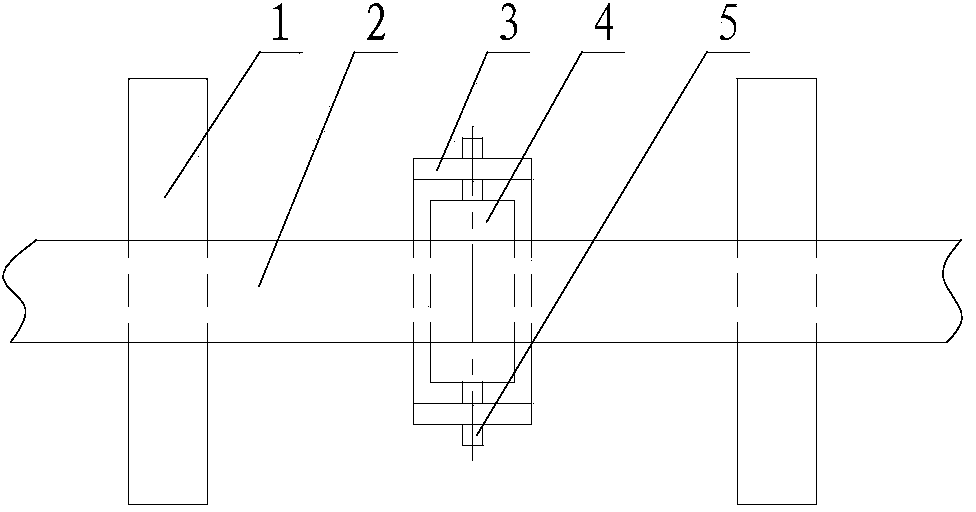

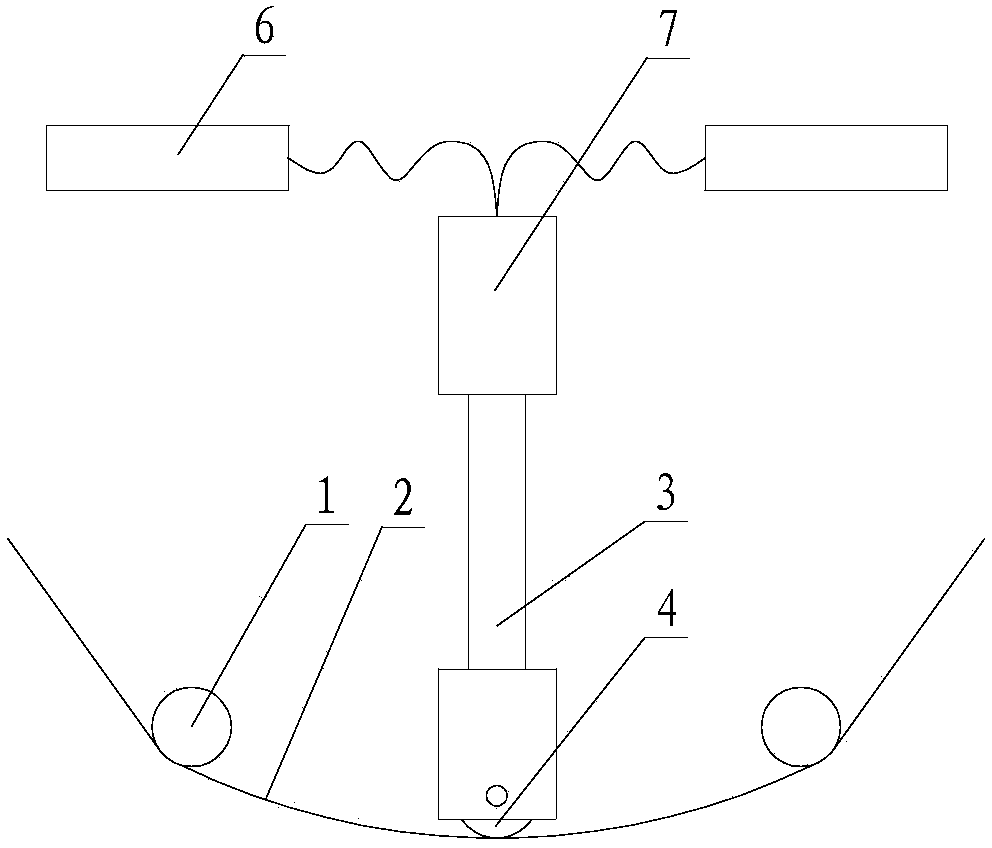

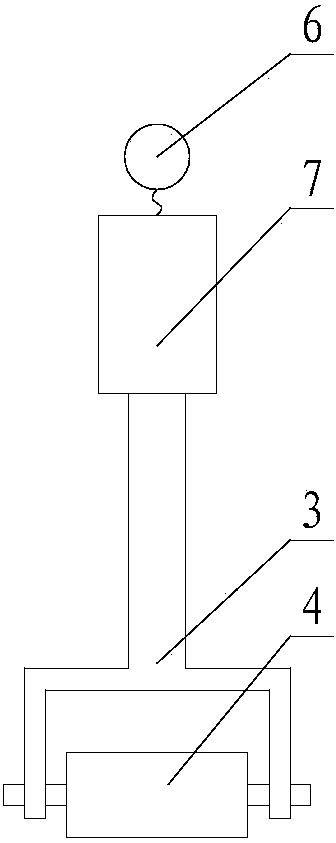

[0017] An automatic tension detection device for a wrapping machine, including a pressure sensor 7, a bracket 3 and a guide wheel 4, the guide wheel is installed on the front end of the bracket through the guide wheel shaft 5, and the guide wheel is vertically pressed against the wrapping belt 2, and the wrapping belt is It refers to the straight line part wound on the outer surface of the two film guide rods 1 on the rotary table of the wrapping machine, and the guide wheel presses against the middle of the straight line part.

[0018] The rear end of the bracket is fixedly mounted on the force-measuring surface of the pressure sensor. The pressure sensor is installed on the turntable of the wrapping machine. The pressure sensor is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com