Honeycomb body consisting of metal foils and method for the production thereof

A technology of honeycomb body and thin plate, applied in the direction of chemical instruments and methods, manufacturing tools, metal processing, etc., to achieve the effect of economical manufacturing, ensuring flow and wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

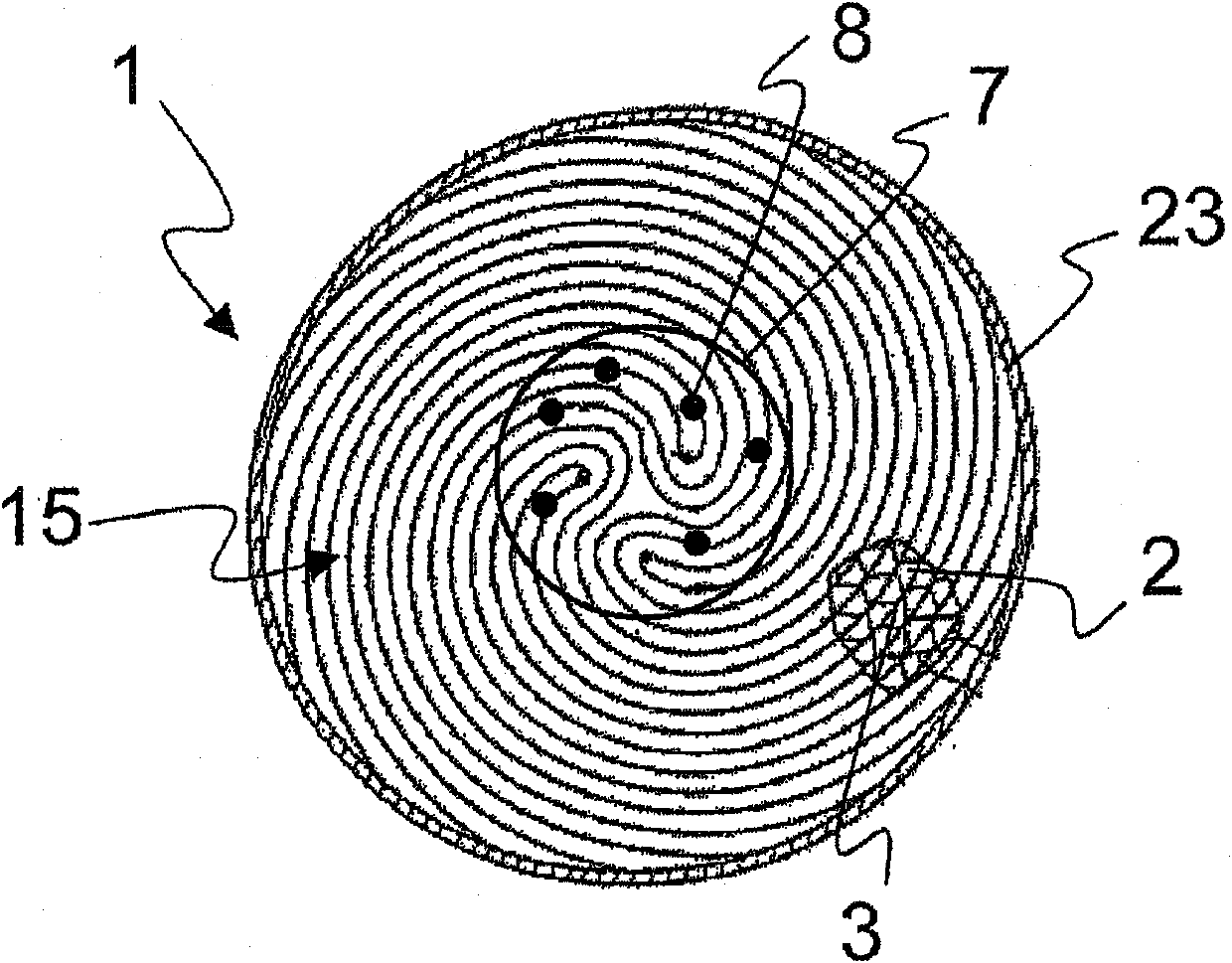

[0055] figure 1 A schematic end view of a honeycomb body 1 is shown, which consists of a smooth sheet metal 2 and a structured sheet metal 3 , which are arranged in a housing 23 . For the present case, the exact shape of the honeycomb structure 15 formed in the housing by the wound sheets 2 , 3 is not critical. In fact, the invention is applicable to metal honeycomb bodies of all known shapes. For example, a region 7 is mentioned here, in which a connection point 8 is formed, for example by brazing, between adjacent sheet metal sheets 2 , 3 , so that the honeycomb body 1 has a high stiffness at this connection point. Separate connection points 8 are optionally provided in this region 7 , which can be positioned in any desired manner within the honeycomb body 1 , of course also in relation to the connection between the metal sheets 2 , 3 and the housing 23 .

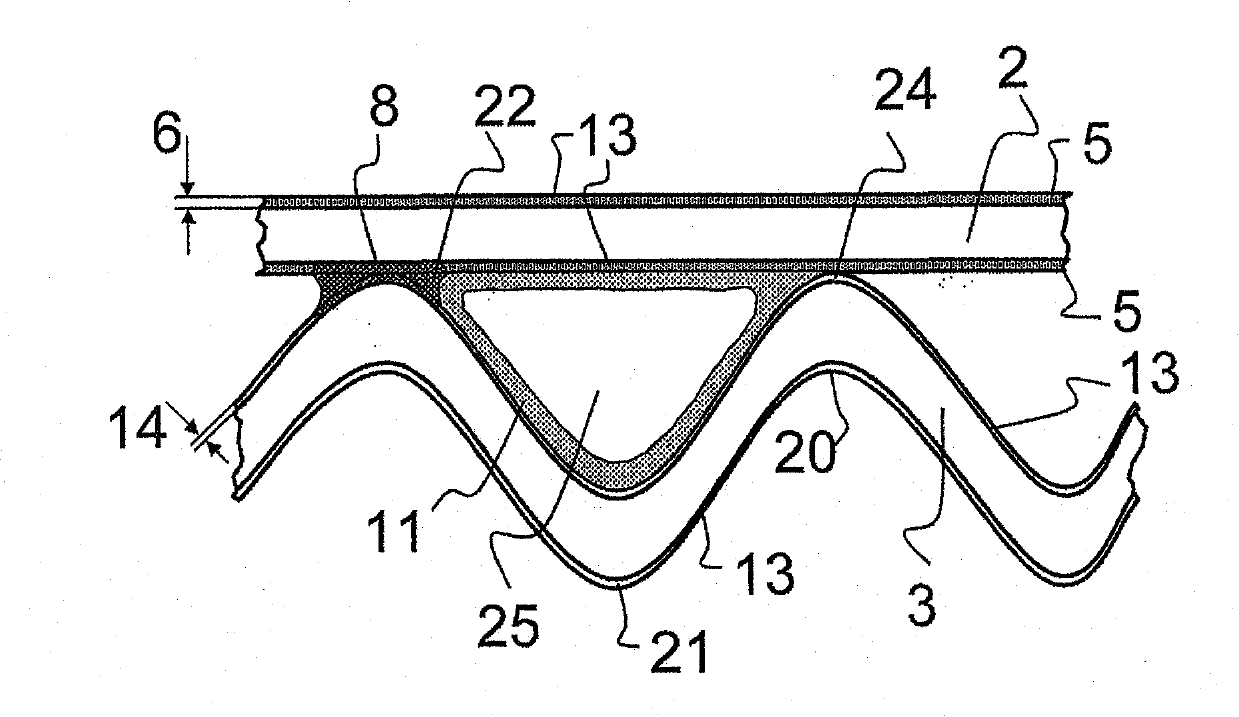

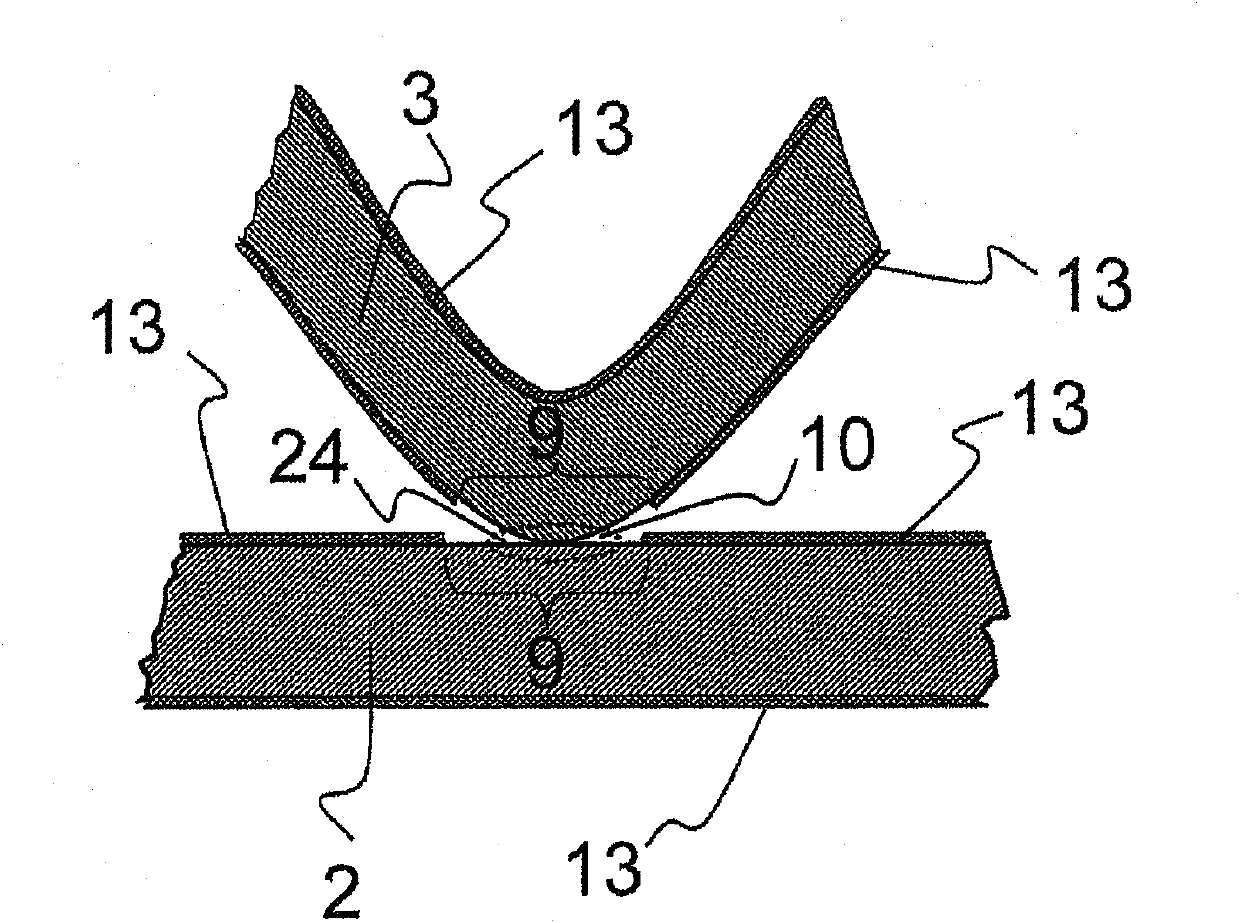

[0056] figure 2 The contact points 24 between the smooth sheet metal 2 and the structured sheet metal 3 in the hone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com