Production method of environment-friendly hygroscopic and sweat releasing fabric

A moisture-absorbing and sweat-wicking, production method technology, applied in dyeing, fabric surface trimming, textiles, etc., can solve the problems of waste liquid and fabrics that are difficult to degrade, environmental hazards, fabrics feel dry, etc., and achieve long-lasting moisture absorption and sweat-wicking functions , Improve hydrophilic performance, soft and plump hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Spinning process:

[0020] 1. Selection of raw materials:

[0021] Egyptian long-staple cotton: 60kg; American Pima cotton: 40kg.

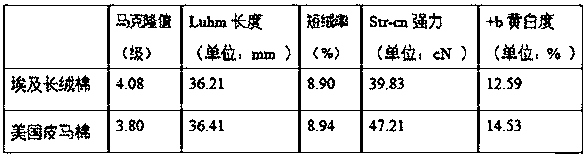

[0022] The following table is the HVI test comparison result table of raw materials:

[0023]

[0024] 2. Spinning process:

[0025] The double combing-ring spinning process is adopted, and the equipment passed through are the blowing disc FA002D, the opener A035E, the porcupine opener FA106, the coiler A076F, the carding machine FA231C, the pre-parallel machine FA311F, the first pass Sliver winding machine CL15, first-pass combing machine CJ60, second-pass sliver winding machine CL15, second-pass combing machine CJ60, end-parallel machine RSB-D40C, roving frame FA458A, spinning frame DTM129, automatic winder.

[0026] The characteristics are: the key is in the spinning process, when twisting, the designed twist coefficient is 260, and finally the low twist yarn with the twist coefficient of 260 is obtained by winding.

[0027] Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com