Antifoaming dust suppressant and preparation method thereof

The technology of a dust suppressant and defoamer, which is applied in the field of defoaming dust suppressant and its preparation, can solve problems such as mine safety production accidents, excessive foam, and affecting the effect of spray dust suppression, so as to ensure normal and safe operation and improve dust suppression. Efficiency, the effect of ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

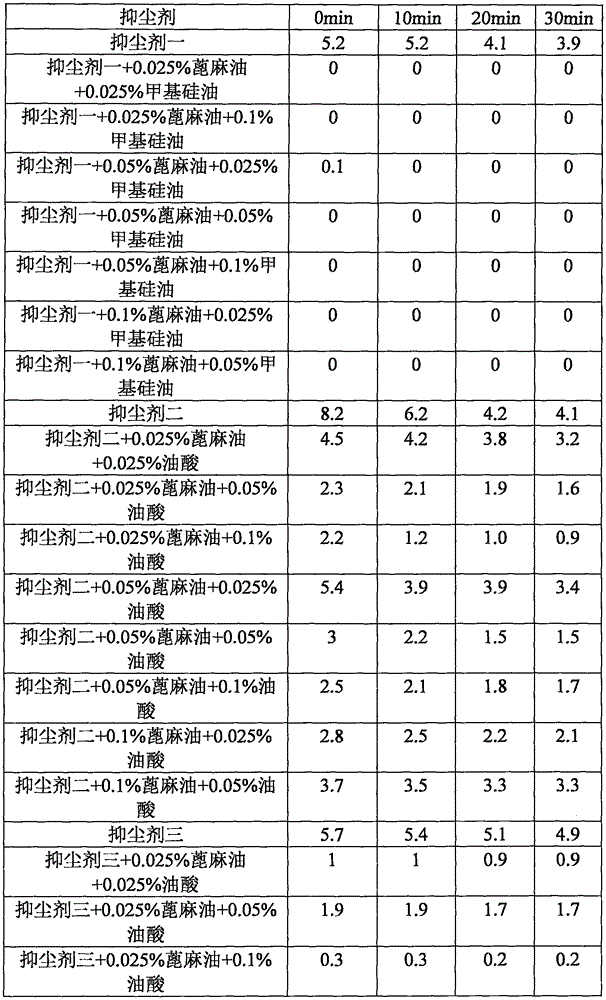

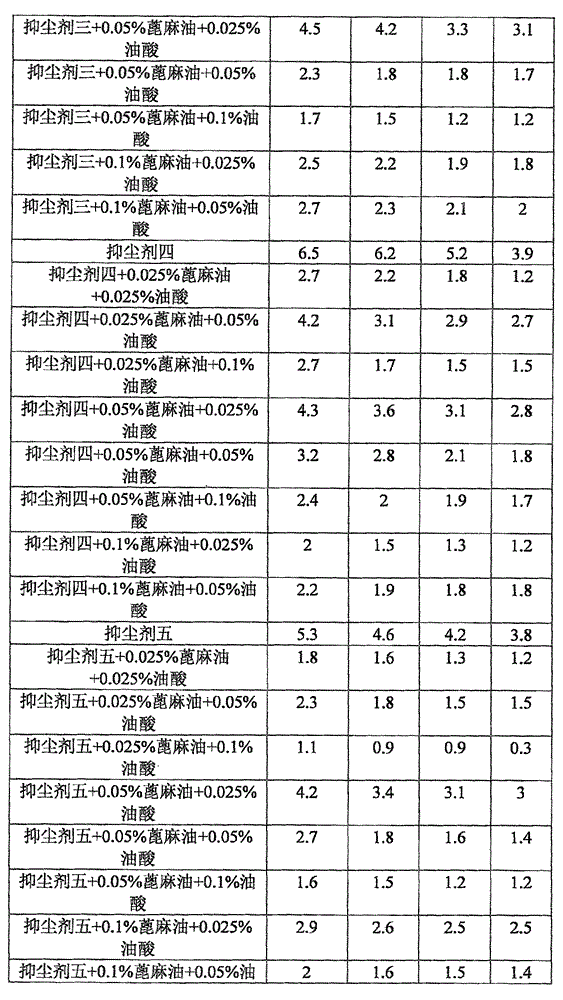

Examples

Embodiment 1

[0050] As an embodiment of the present invention, the preparation method of described dust suppressant comprises the following steps:

[0051] 1) Weigh 2.2g of OP-20 and dissolve it in 10g of deionized water, and dissolve it completely for later use; in addition, weigh 2.05g of sodium dodecylbenzenesulfonate and dissolve it in 10g of deionized water, and dissolve it completely for later use; then The two were mixed, and after standing for 20 minutes, 9.08 g of deionized water was added to the mixed solution, and left for 10 minutes to obtain the first solution (A1), which was set aside;

[0052] 2) Weigh 2.84g of ethylene glycol and dissolve it in 20g of deionized water. After completely dissolving, add 10.49g of deionized water and let it stand for 15 minutes to obtain the second solution (B1) for later use;

[0053]3) Weigh 2.75g of sodium silicate and dissolve it in 20g of deionized water, then add 10.58g of deionized water after it is completely dissolved, and let it stand...

Embodiment 2

[0056] As an embodiment of the present invention, the preparation method of described dust suppressant comprises the following steps:

[0057] 1) Weigh 0.95g of AEO-9 and dissolve it in 10g of deionized water, and dissolve it completely for later use; in addition, weigh 1.50g of sodium dodecylsulfonate and dissolve it in 10g of deionized water, and dissolve it completely for later use; then mix the two Mix, then add 10.88g deionized water, let stand for 8min, obtain the first solution (A2), set aside;

[0058] 2) Weigh 0.85g of ethanol, dissolve it in 20g of deionized water, after completely dissolving, add 12.48g of deionized water, and let it stand for 15min to obtain the second solution (B2) for later use;

[0059] 3) Weigh 0.65g of potassium sulfate and dissolve it in 20g of deionized water, then add 12.68g of deionized water after it is completely dissolved, and let it stand for 18min to obtain the third solution (C3) for later use;

[0060] 4) The first solution (A2), t...

Embodiment 3

[0062] 1) Weigh 0.55g TX-7 and dissolve it in 10g of deionized water, and dissolve it completely for later use; in addition, weigh 1.50g of sodium dodecylbenzenesulfonate and dissolve it in 10g of deionized water, and dissolve it completely for later use; Mixed, then add 11.25g deionized water, let stand for 8min, obtain the first solution (A3), for subsequent use;

[0063] 2) Weigh 1.95g of polyethylene glycol, dissolve it in 20g of deionized water, and after it is completely dissolved, add 11.38g of deionized water and let it stand for 15 minutes to obtain the second solution (B3) for later use;

[0064] 3) Weigh 2.05g of strontium carbonate and dissolve it in 20g of deionized water, then add 11.28g of deionized water after completely dissolving, and let stand for 22min to obtain the third solution (C3) for later use;

[0065] 4) The first solution (A3), the second solution (B3) and the third solution (C3) were mixed evenly, and the dust suppressant (dust suppressant 3) was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com