Water purifier or water purifying plant with circulating filtration function of filter elements and manufacturing method

A water purification equipment and circulating filtration technology, applied in the field of liquid purification treatment and water quality, can solve the problems of limited number of filter elements, the taste of purified water is not perfect and sweet, and pure water is not ideal, etc., to achieve cost-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

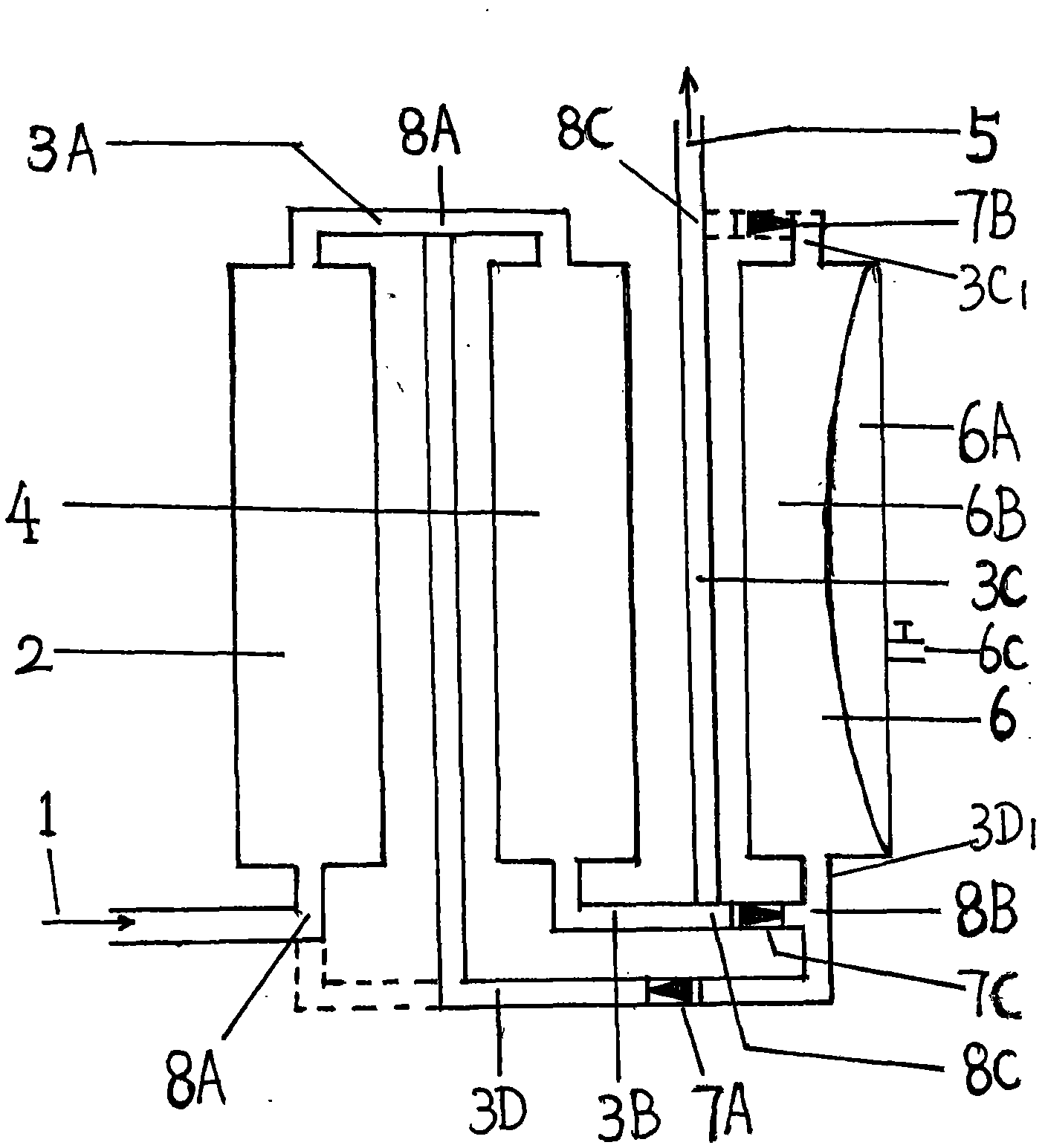

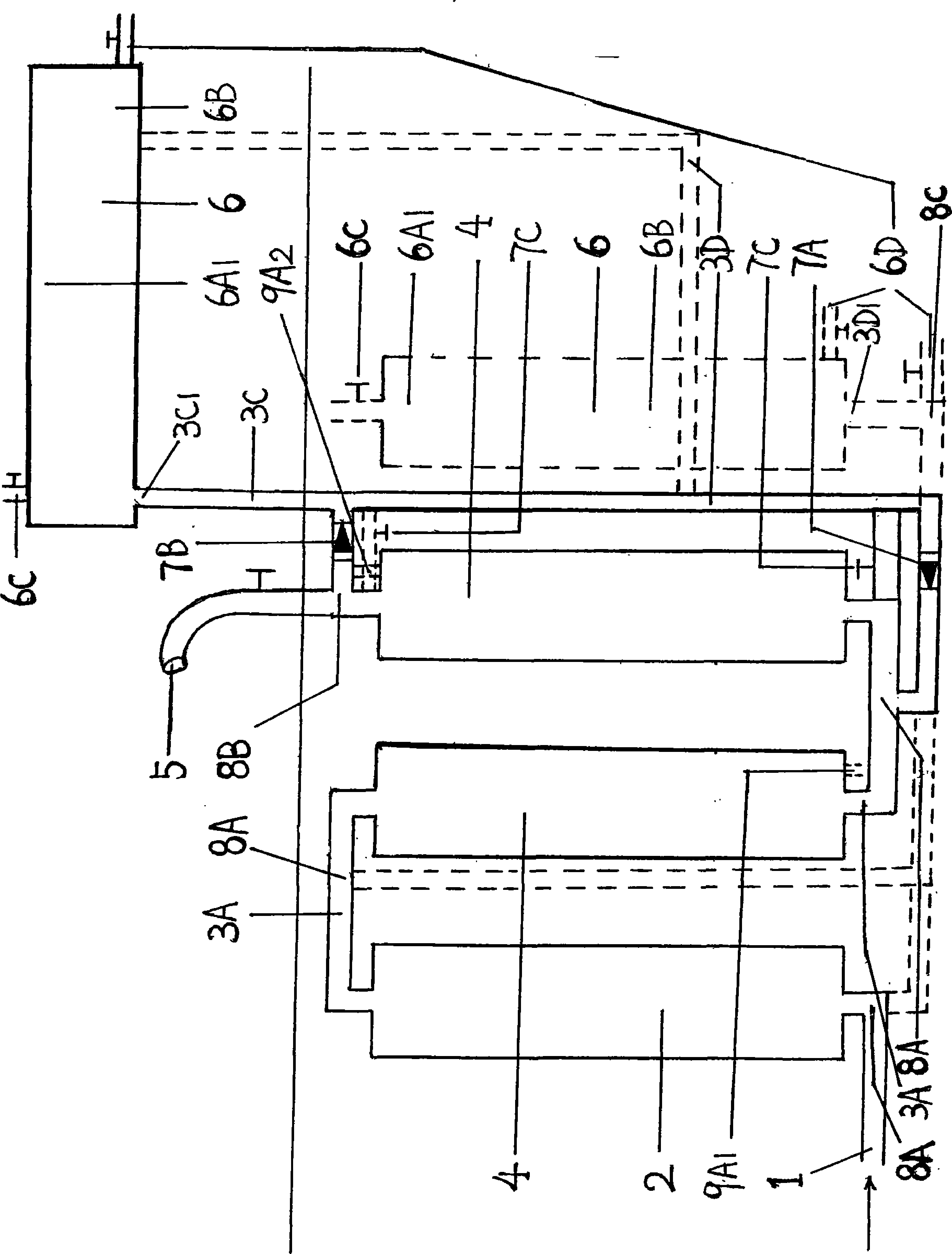

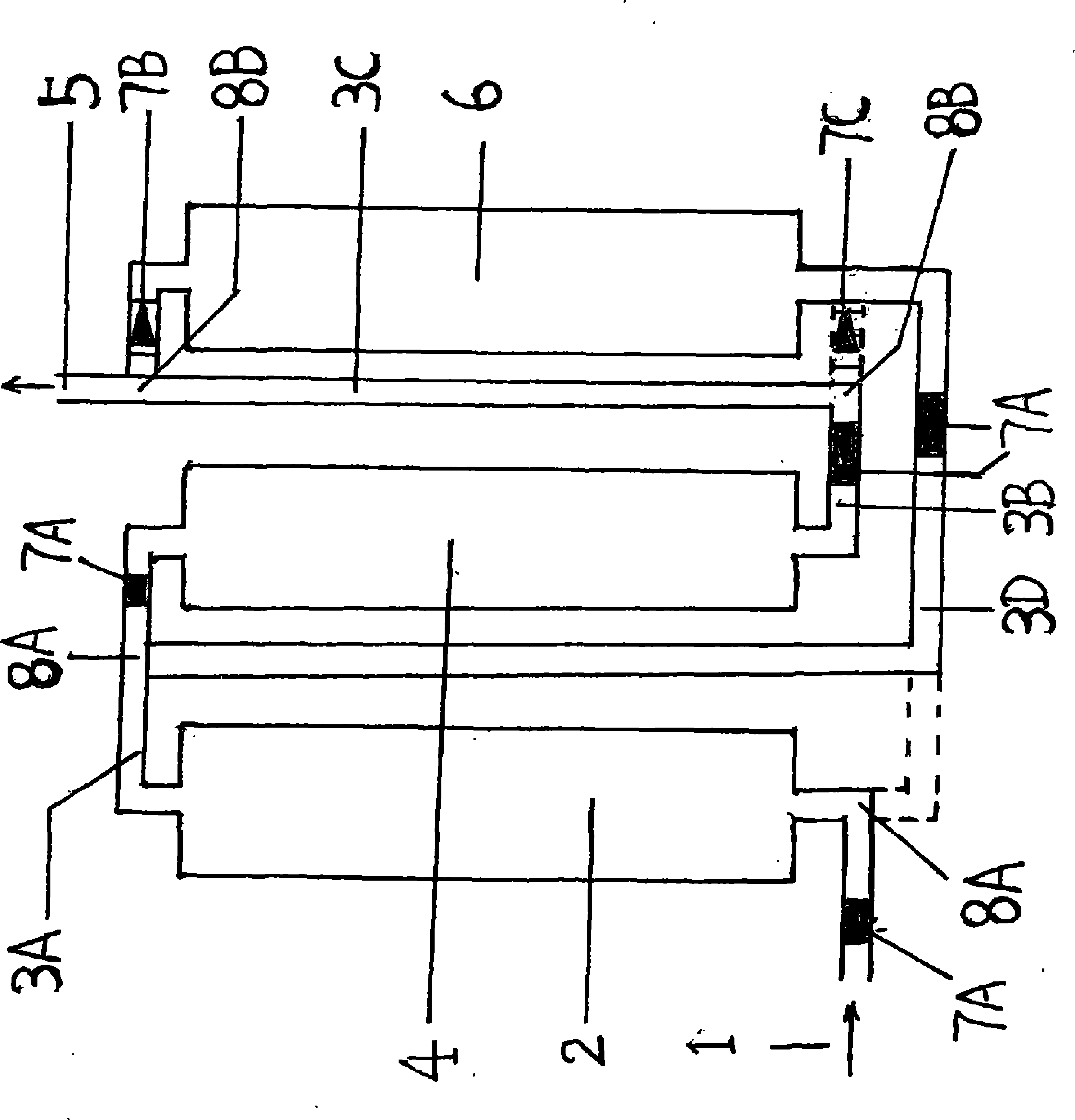

[0068] The specific embodiment: describe embodiment 1 of the present invention below in conjunction with accompanying drawing and a preferred embodiment:

[0069] figure 1 and figure 2 It is a structural cross-sectional diagram of a water purifier or water purification equipment that is circulated and filtered by the filter element:

[0070] (1) The original state of the filter: all the inlet and outlet valves are in the closed state.

[0071] (2), the process of manufacturing purified water or pure water:

[0072] Open the raw water inlet (1), and the raw water passes through the pre-filter element (2) of grade 0 or above, the connecting pipe A (3A), the filter element of grade 1 or above (4), the connecting pipe B (3B), and the purified water Or pure water enters into the water storage chamber (6B) with air pressure water storage chamber or bucket (6) for storage, the gas in the air bag (6A) is compressed, and when the clean water outlet or the next stage filter element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com