A high cleanliness dust removal equipment

A dust removal equipment and high cleanliness technology, which is applied in the field of high cleanliness dust removal equipment, can solve the problems of high cost and general dust removal effect, achieve the effect of improving the effect, avoiding excessive water vapor, and improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

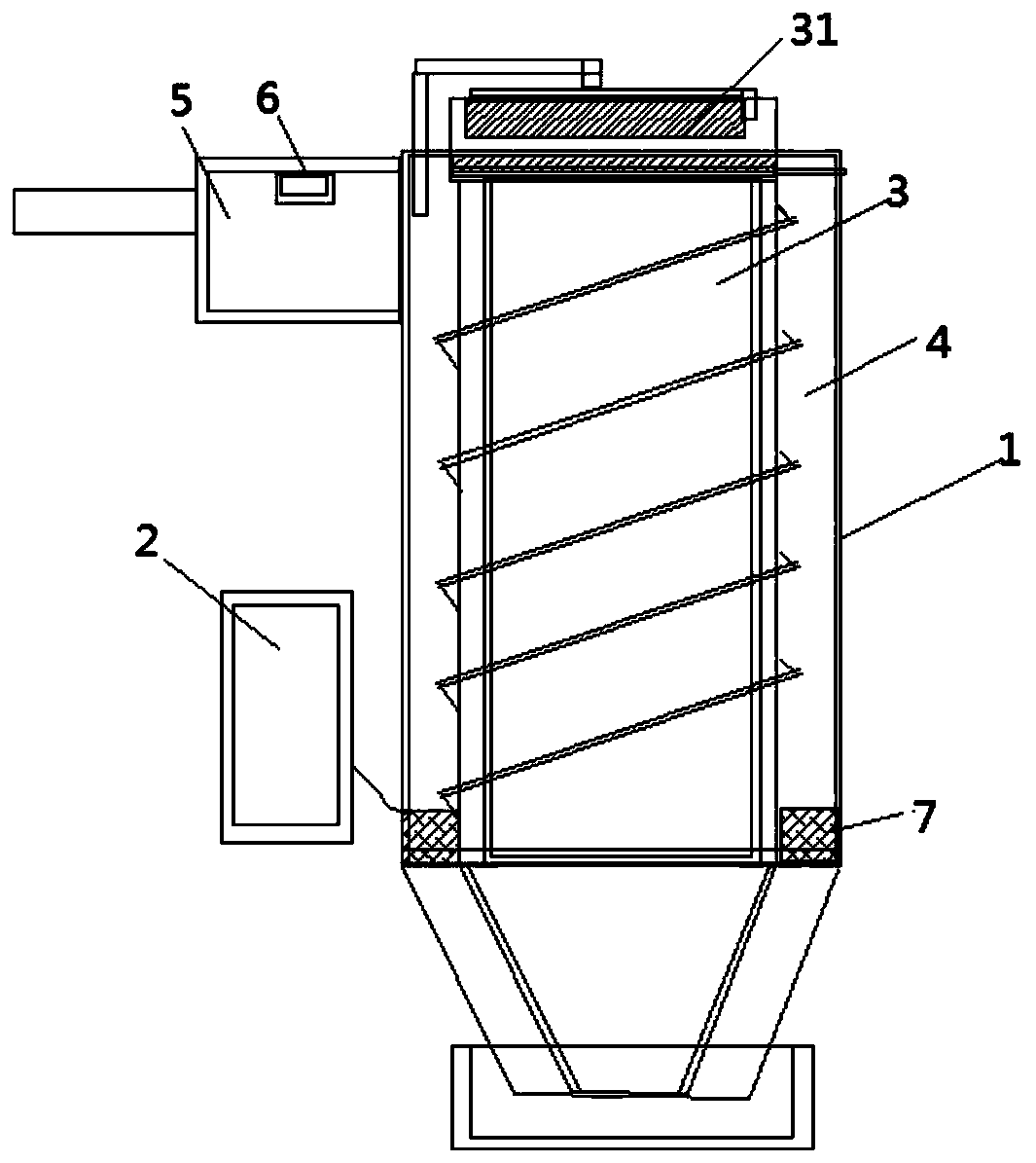

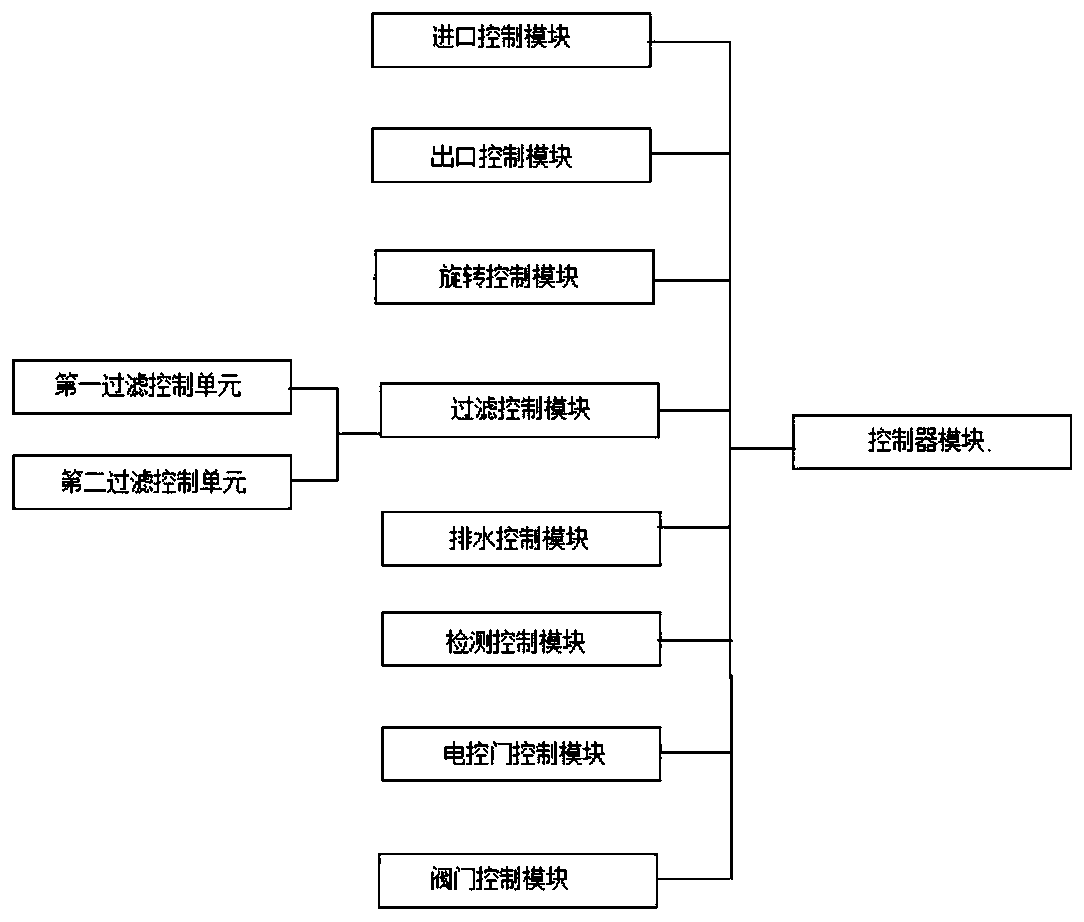

[0022] As shown in the figure, a high-cleanliness dust removal equipment includes: a housing 1 and a control device 2, the housing 1 is provided with a set of air inlets and an air outlet, and the housing 1 is provided with an inner cavity 3 and an outer cavity 4, the air inlet is provided with a gas collection chamber 5, the inner cavity 3 is located inside the outer cavity 4, a rotating mechanism 41 is provided in the outer cavity 4, and the inner cavity The outlet of the body 3 is provided with a first filter mechanism 31 , the gas collection chamber 5 is provided with a gas detection mechanism 6 , and the rotation mechanism 41 , the first filter mechanism 32 and the gas detection mechanism 6 are all connected to the control device 2 .

[0023] In this embodiment, the outlet of the inner cavity 3 is provided with an electric control door and a ventilation pipe, and the ventilation pipe is connected with the outer cavity, and the ventilation pipe is provided with an electric ...

Embodiment 2

[0030] As shown in the figure, a high-cleanliness dust removal equipment includes: a housing 1 and a control device 2, the housing 1 is provided with a set of air inlets and an air outlet, and the housing 1 is provided with an inner cavity 3 and the outer cavity 4, the air inlet is provided with a gas collection chamber 5, the inner cavity 3 is arranged inside the outer cavity 4, a rotating mechanism 41 is provided in the outer cavity 4, and the inner cavity The outlet of the body 3 is provided with a first filter mechanism 31 , the gas collection chamber 5 is provided with a gas detection mechanism 6 , and the rotation mechanism 41 , the first filter mechanism 32 and the gas detection mechanism 6 are all connected to the control device 2 .

[0031] In this embodiment, the outlet of the inner cavity 3 is provided with an electric control door and a ventilation pipe, and the ventilation pipe is connected with the outer cavity, and the ventilation pipe is provided with an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com