Preparation method of extra high concentration wort

A technology of extra-high-concentration wheat and high-concentration wheat is applied in the field of preparation of extra-high-concentration wort, which can solve the problems of difficulty in filtering wort and prolonged filtering time, and achieve breakthroughs in low utilization rate of raw materials, soft and harmonious taste, and saving saccharification. effect of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

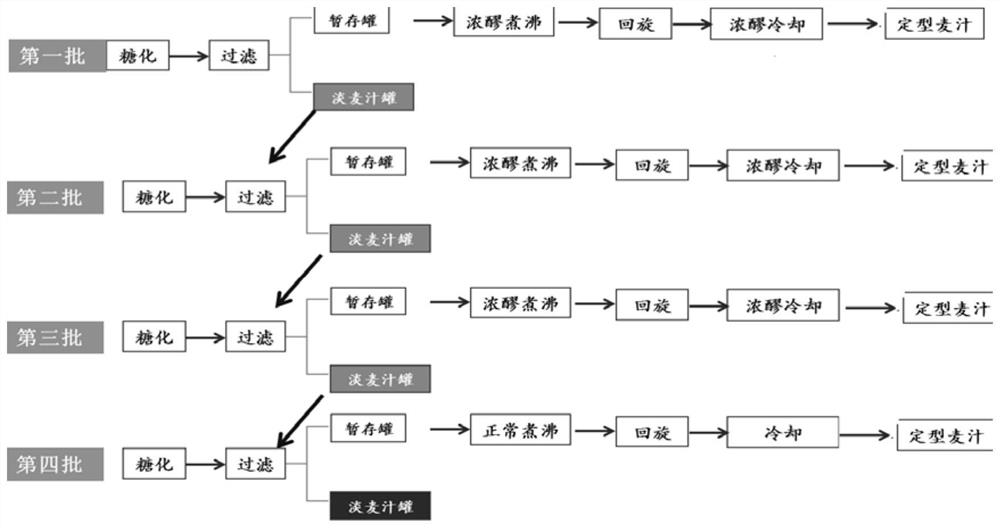

[0034] The embodiment of the present invention provides a method for preparing extra-high-concentration wort, including a process for preparing extra-high-concentration wort in batches, and the specific steps are as follows:

[0035] S1. The first batch of wort preparation process:

[0036] In the saccharification pot, stop processing the crushed malt, then raise the temperature to 63-68°C, saccharify for 60-80min, after passing the iodine test, then raise the temperature to 76-78°C, then transfer to the filter tank for filtration;

[0037] When the filtered wort reveals the bad layer, the first wort filtration is completed, and the first wort enters the wort temporary storage tank;

[0038] After the first wort filtration is completed, add hot water at 76-78°C to the filter tank, and wash the wort remaining in the grains, which is called the second wort filtration;

[0039] Mix 70% to 100% of the second wort with the first wort and put it into the boiling pot for thick mash ...

Embodiment 1

[0089] This embodiment provides a method for preparing extra-high-concentration wort, including the preparation of the first batch of wort and the preparation of the second batch of wort. The specific methods are as follows:

[0090] 1. Preparation of the first batch of wort:

[0091] (1-1) In the saccharification pot, rest the crushed malt at 45°C for 40 minutes, then raise the temperature to 63°C, and saccharify for 60 minutes. After passing the iodine test, raise the temperature to 76°C and transfer to the filter tank for filtration ;

[0092] (1-2) When the filtered wort reveals the bad layer, the filtration of the first wort is completed, and the first wort enters the wort temporary storage tank;

[0093] (1-3) After the first wort filtration is completed, add hot water at 76°C to the filter tank, and after washing the wort remaining in the grains, it is called the second wort filtration. The residual sugar concentration of juice filtration is 0.8°P;

[0094] (1-4) Aft...

Embodiment 2

[0103] This embodiment provides a method for preparing extra-high-concentration wort, including the preparation of the first batch of wort and the preparation of the second batch of wort. The specific methods are as follows:

[0104] 1. Preparation of the first batch of wort:

[0105] (1-1) In the saccharification pot, rest the crushed malt at 50°C for 40 minutes, then raise the temperature to 65°C, and saccharify for 65 minutes. After passing the iodine test, raise the temperature to 78°C and transfer to the filter tank for filtration ;

[0106] (1-2) When the filtered wort reveals the bad layer, the filtration of the first wort is completed, and the first wort enters the wort temporary storage tank;

[0107] (1-3) After the first wort filtration is completed, add hot water at 76°C to the filter grains, and after washing the wort remaining in the grains, it is called the second wort filtration. The residual sugar concentration of juice filtration is 1.5°P;

[0108] (1-4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com