A kind of solid raw material pretreatment device and method for nanocomposite preparation

A technology of nano-composite material and pretreatment device, which is used in the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc., can solve the problems of poor screening effect, rejection, difficult impurities, etc. Filter effect, avoid accumulation, and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

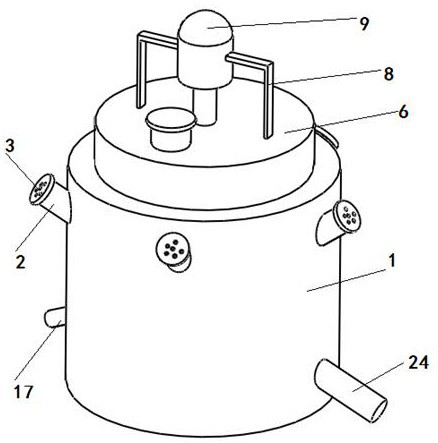

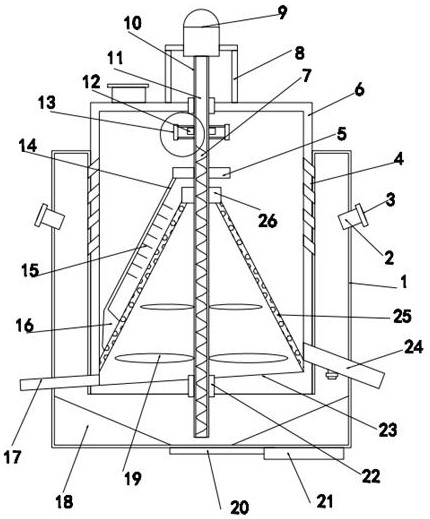

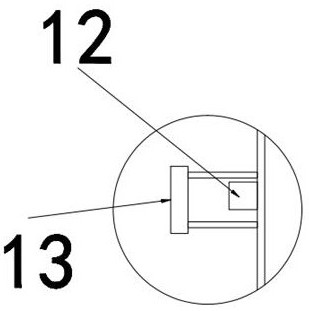

[0029] see Figure 1-3 , in an embodiment of the present invention, a solid raw material pretreatment device for preparing nanocomposite materials, comprising an inner box 6 and an outer box 1 arranged outside the inner box 6, the upper end of the inner box 6 is provided with a feeding port and is arranged on a feeding The cover at the port, the upper end of the inner box 6 is provided with a drive motor 9 through a fixed frame 8, the output end of the drive motor 9 is connected to the upper end of the rotating shaft 10, and the lower end of the rotating shaft 10 runs through the upper and lower end surfaces of the inner box 6;

[0030] The lower end surface of the outer box 1 is provided with a discharge port, and the discharge port is equipped with a movable sealing plate 20 for blocking. The right end of the movable sealing plate 20 is connected to a push cylinder 21 for driving it to move left and right. The bottom of the outer box 1 where the material port is located is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com