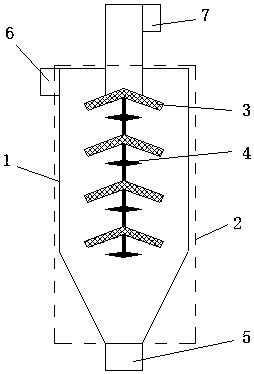

Method and device for electromagnetic collaborative electrofiltration dust removal

A dust removal device and electromagnetic technology, which can be applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problem of difficulty in fine particles, and achieve the effects of efficient separation and removal, enhanced removal, and economic cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

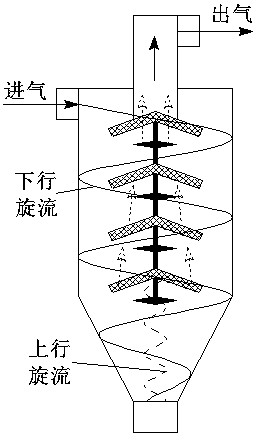

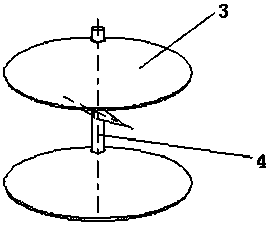

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Purify the tail gas of the closed calcium carbide furnace by using the electromagnetic cooperative electric filter dust removal method

[0041] At present, most of the calcium carbide industry in my country adopts closed calcium carbide furnaces, which will produce 400m of furnace gas at 700-1000°C for every 1 ton of calcium carbide produced in the closed calcium carbide furnace. 3 , in which the dust content is 100~250g / Nm 3 , most of the dust is composed of 0.1-20 μm particles with tar adhered to the surface, and the fine particles are difficult to remove efficiently.

[0042] In this embodiment, the tail gas of the sealed calcium carbide furnace uses the conventional cyclone dust removal technology to generate a cyclone flow field at a wind speed of 30m / s to remove large particles, and the difficult-to-remove fine particles enter the corona region generated by the corona electrode for charging, and then the charged particles In the electric field generate...

Embodiment 2

[0048] Example 2: Purify smelting flue gas by using electromagnetic cooperative electric filtration dust removal method

[0049] The non-ferrous metal pyrometallurgy process (including drying, sintering, roasting, smelting, blowing, fuming, volatilization, casting, etc.) produces a large amount of smoke, which contains smoke and dust, which contains metals and various valuable elements. In order to improve the recovery rate of smelting, comprehensively recover valuable elements, and reduce environmental pollution, the dust must be collected from the flue gas.

[0050] In this embodiment, the smelting flue gas uses the conventional cyclone dust removal technology to generate a cyclone flow field at a wind speed of 23m / s to remove large particles, and the difficult-to-remove fine particles enter the corona region generated by the corona electrode for charging, and then the charged particles are in the corona area. The electric field generated by the corona electrode (cathode, do...

Embodiment 3

[0055] Example 3: Purify yellow phosphorus tail gas using electromagnetic cooperative electric filtration dust removal method

[0056] The dust concentration in the yellow phosphorus tail gas produced by my country's yellow phosphorus industry is relatively high, generally 30-60g / m 3 , even higher than 100g / m under extreme working conditions 3 . In the production of yellow phosphorus, dust removal in yellow phosphorus production can be divided into wet dust removal and dry dust removal. Most domestic yellow phosphorus production lines use wet dust removal technology, but wet dust removal not only consumes water, but also produces a large amount of sludge phosphorus. A large amount of phosphorus-containing sewage is produced.

[0057] In this embodiment, the yellow phosphorus tail gas utilizes the conventional cyclone dedusting technology to generate a cyclone flow field at a wind speed of 16m / s to remove large particles, and the difficult-to-remove fine particles enter the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com