Treatment method for high-precision rolled copper foil oxide treatment on produced wastewater

A treatment method and a technology of rolling copper foil, which are applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve the problems of inability to meet the discharge standards of wastewater treatment and increase the concentration of pollutants, and achieve good promotion and application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

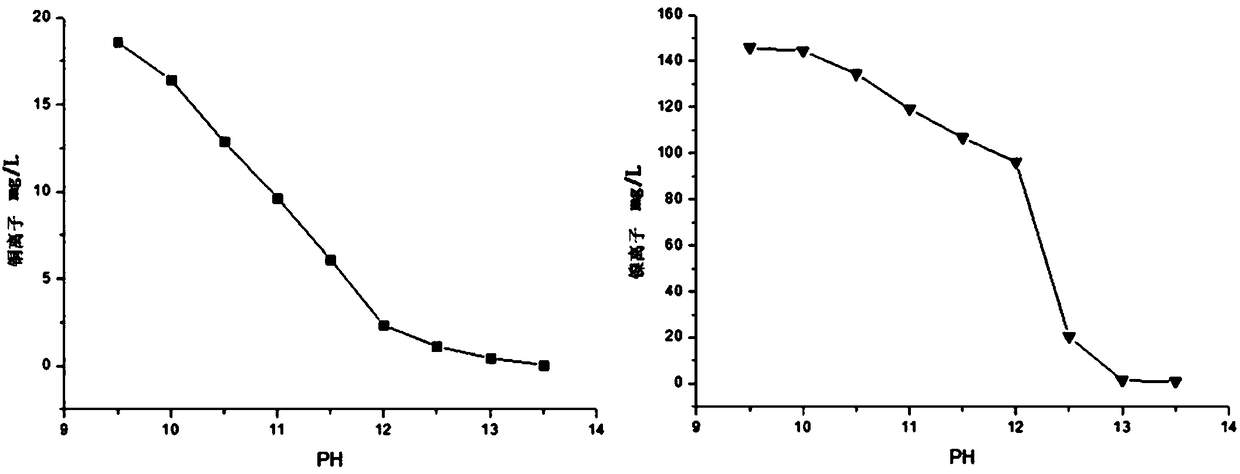

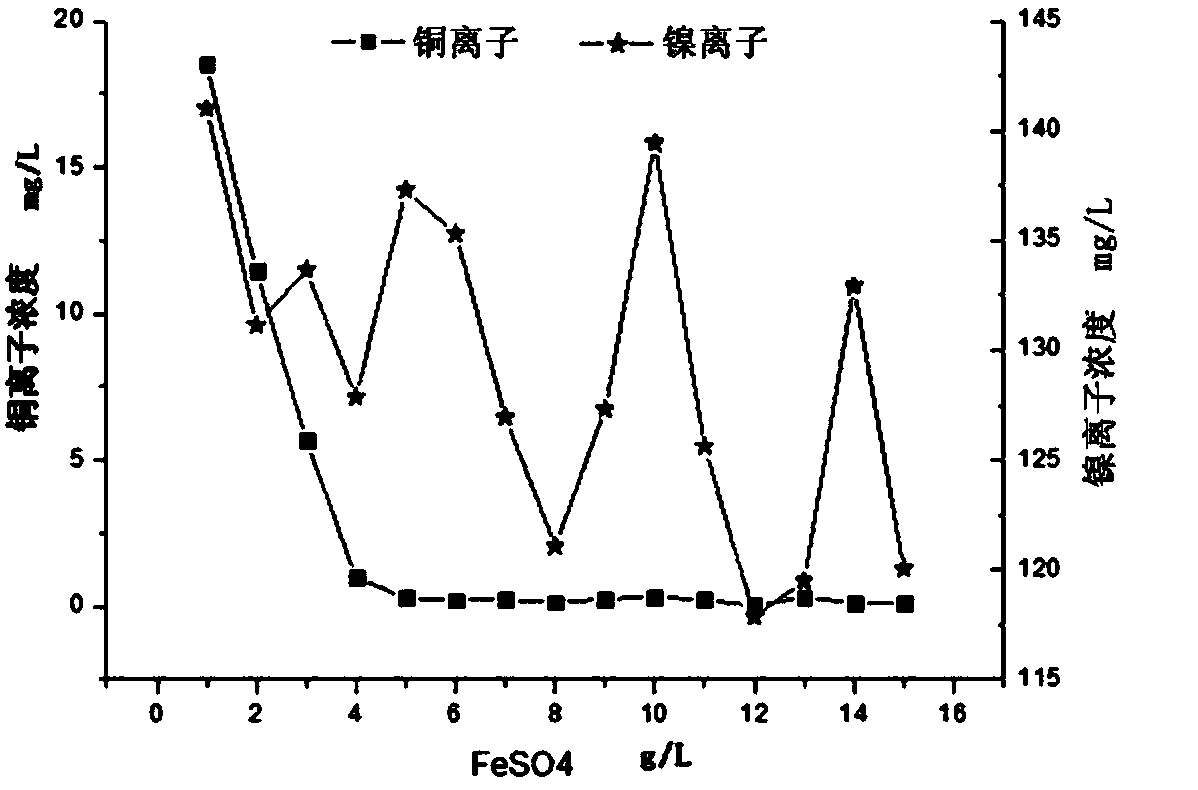

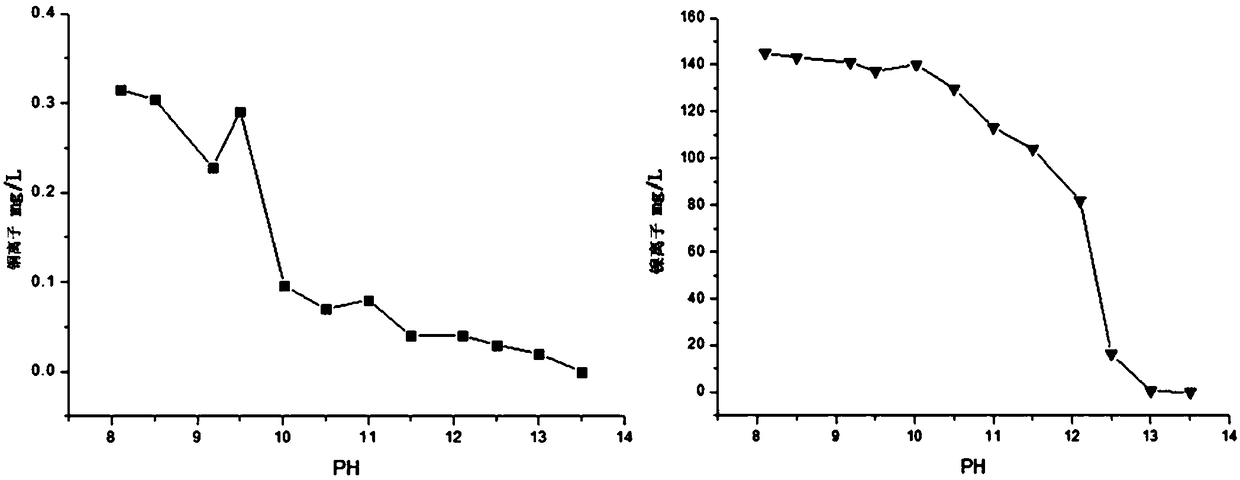

[0021] This application provides a method for treating wastewater produced by blackening treatment of high-precision rolled copper foil. First, sodium hydroxide is added to the wastewater to be treated to adjust the pH, then ferrous sulfate is added, and then fully stirred, and then mixed The coagulant and flocculant are precipitated again, and then filtered to obtain the filter residue and filtrate, then add hydrochloric acid to the filtrate to adjust the pH, and finally discharge the filtrate after testing that the content of copper ions and nickel ions in the filtrate reaches the standard.

[0022] In one embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com