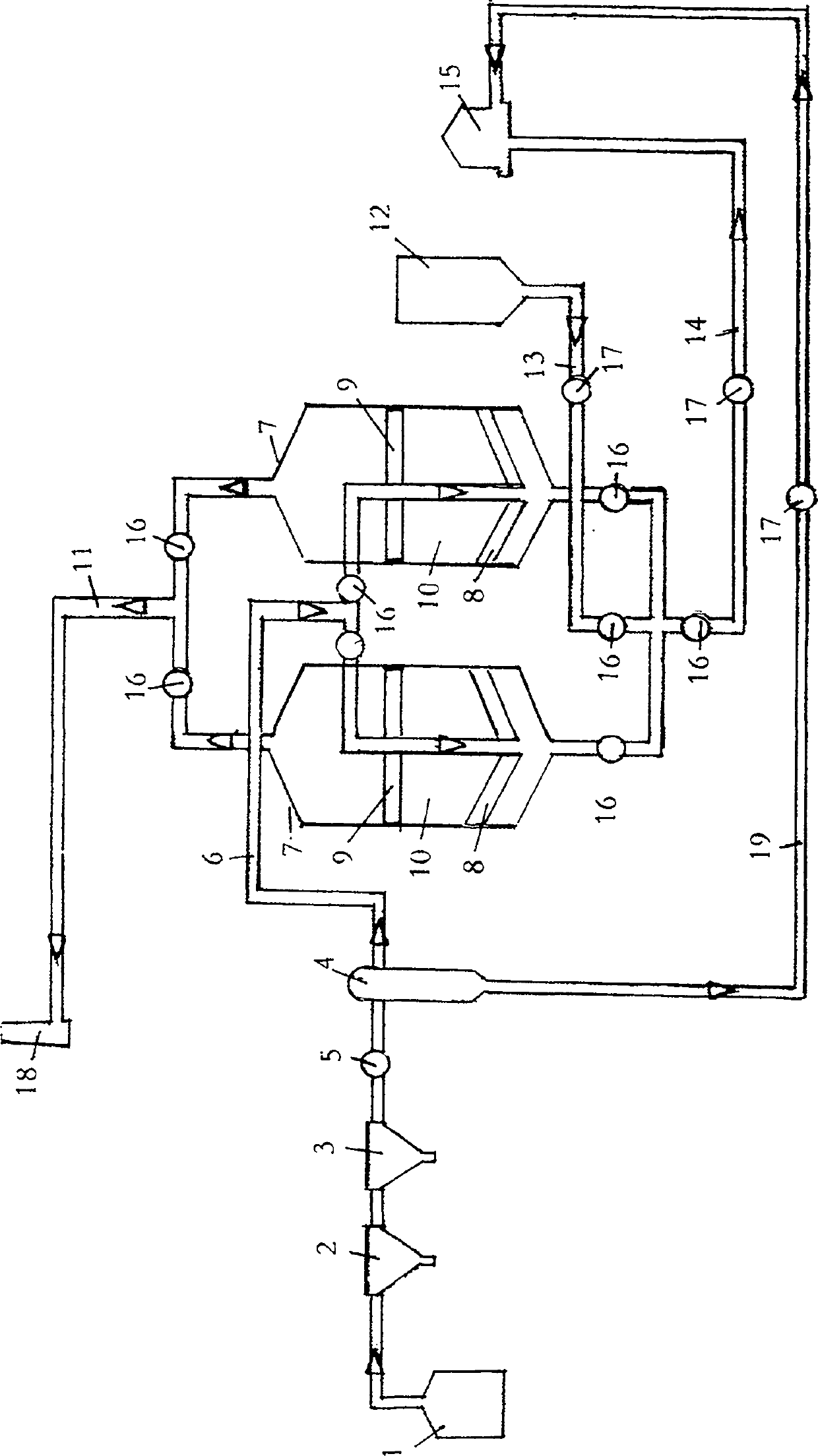

Coal-fired power plant flue gas sulfur dioxide catalytic desulfurization production and technical flow

A technology for sulfur dioxide and coal-fired power plants, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., to achieve the effects of fast reaction rate, saving equipment investment, and high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

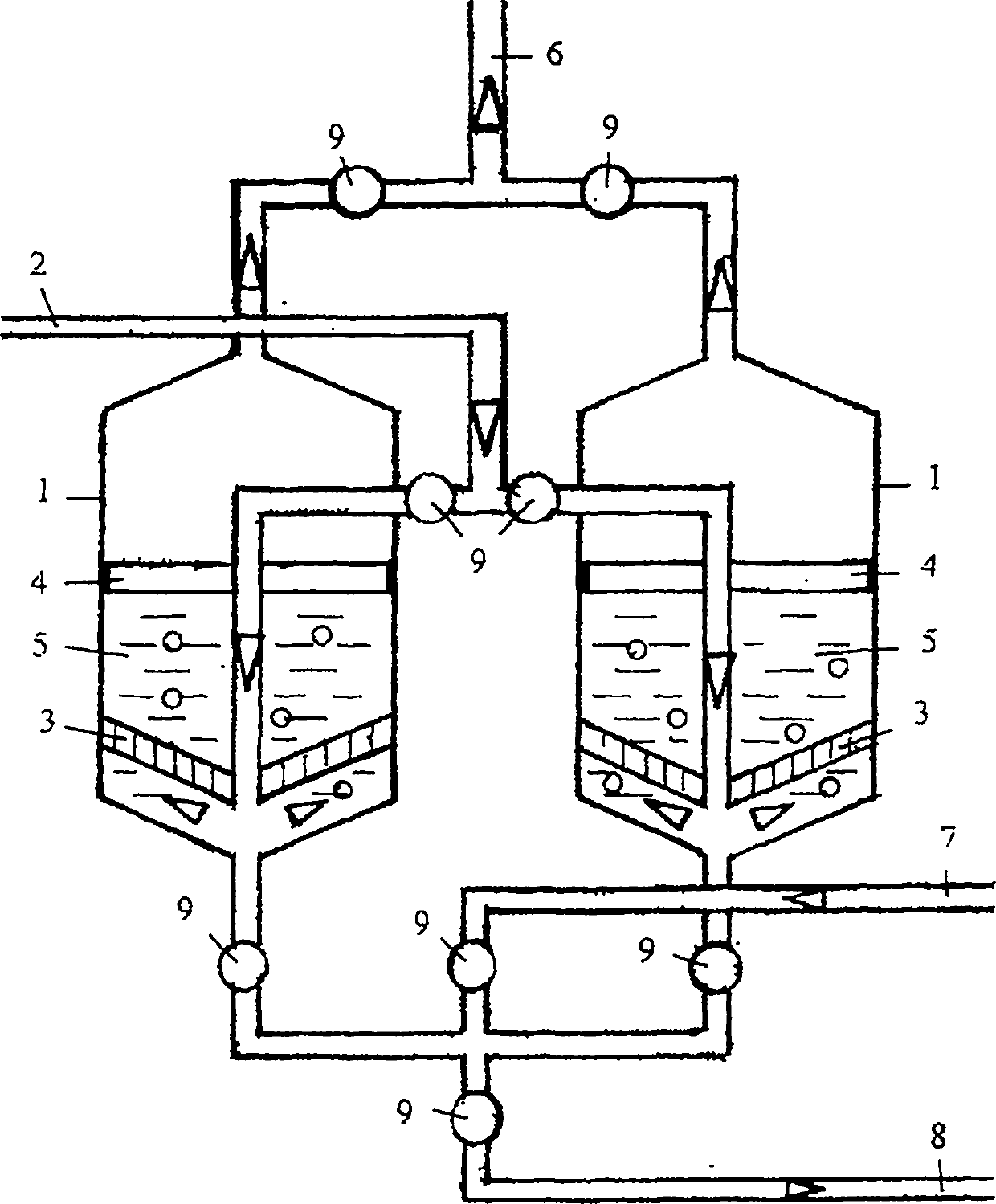

[0136] "Coal-fired power plant flue gas sulfur dioxide SO2, catalytic desulfurization production and process flow" is the application of catalysts in coal-fired power plant flue gas sulfur dioxide SO2 catalytic desulfurization, the specific implementation method is that coal-fired flue gas sulfur dioxide SO2 passes through the catalytic tower , Catalyst to achieve filtration, complete desulfurization method, catalytic filtration method, suitable for flue gas desulfurization of coal-fired enterprises of different scales, regardless of large, medium, or small coal-fired power plant desulfurization, have a wide range of adaptability.

[0137] (1) One-time investment can be realized, and economic, social and environmental benefits can be seen immediately:

[0138] (2) Make the coal-fired power plant of the enterprise, the sulfur dioxide SO2 desulfurization rate far higher than the standard stipulated by the state;

[0139] (3) Make the surrounding environment of the enterprise's c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com