Mechanical-electrical integration dust removal demister

A technology for mist eliminators and mechanical dust removal, which is applied in the field of dust removal and mist removal devices and mechatronics dust removal and mist removal devices, can solve the problems of high manufacturing cost, use cost and maintenance cost, heavy and complicated equipment, and large space occupation. The effect of high initial investment and operating costs, high dust removal efficiency, and long transformation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

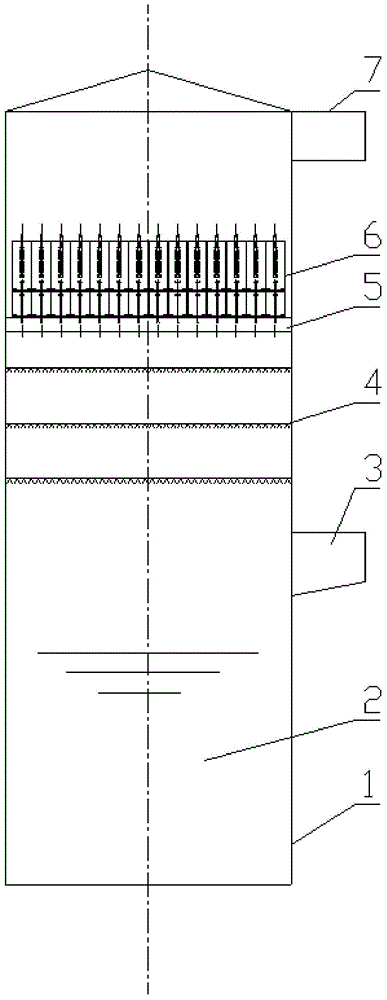

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

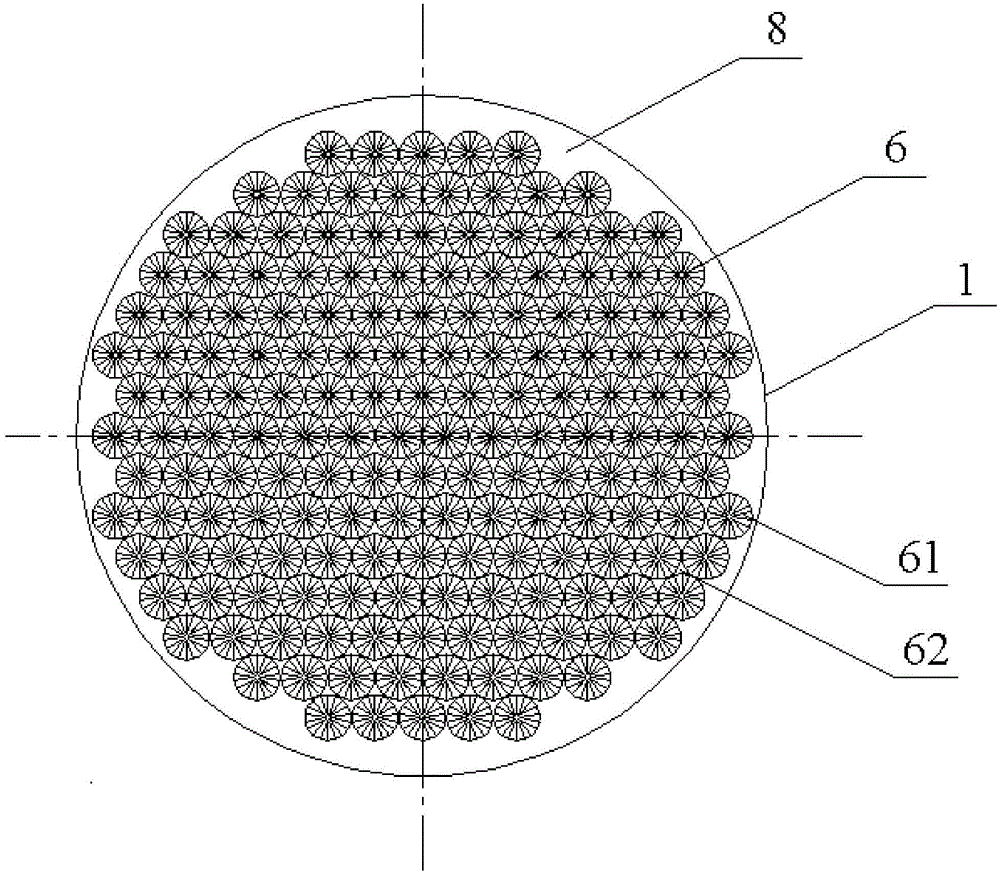

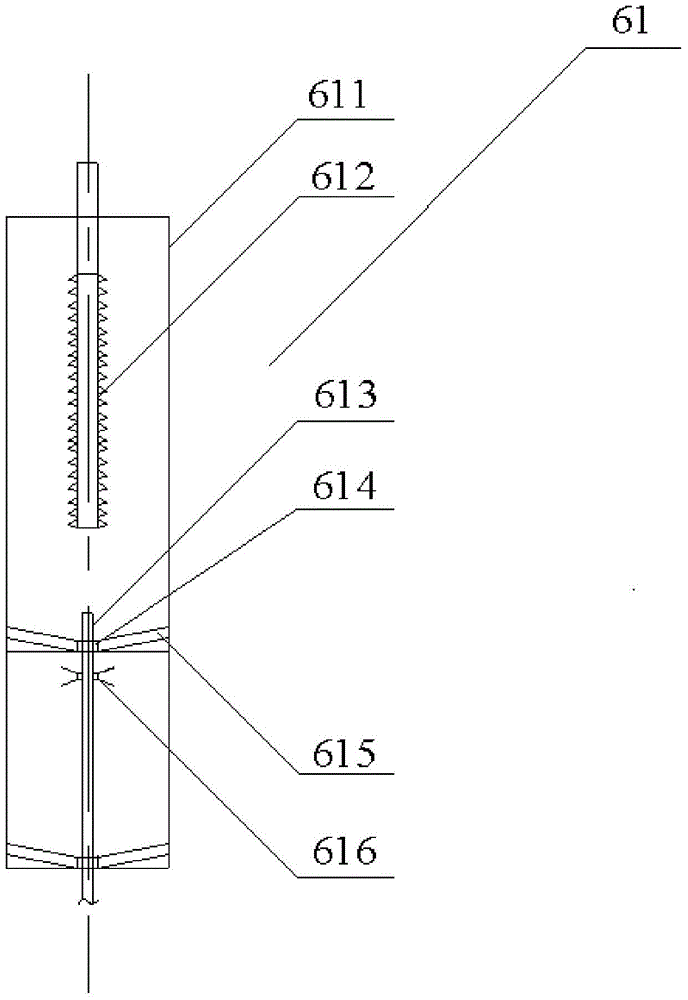

[0025] Such as Figure 1-Figure 3 As shown, the electromechanical integrated dust and mist removal device 6 includes several dust and mist removal units 61, and the gap between adjacent dust and mist removal units 61 is provided with a first blocking plate 62, and the dust and mist removal units 61 include Cyclone cylinder 611, wet electrostatic precipitator and swirl plate mechanical dust and mist removal device, the wet electrostatic precipitator is located in the upper part of the interior of the cyclone cylinder 611, and the swirl plate mechanical dust and mist removal device is located in the The lower part of the interior of the swirl cylinder 611 .

[0026] The shape of the cross-section of the first blocking plate 62 matches the shape of the cross-section of the gap between the adjacent dust and mist removal units 61 .

[0027] The we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com