Aluminum ore crushing machine

An aluminum ore and crusher technology, which is used in solid separation, smoke removal, and air flow to separate solids from solids. , the effect of increasing utilization and reducing work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

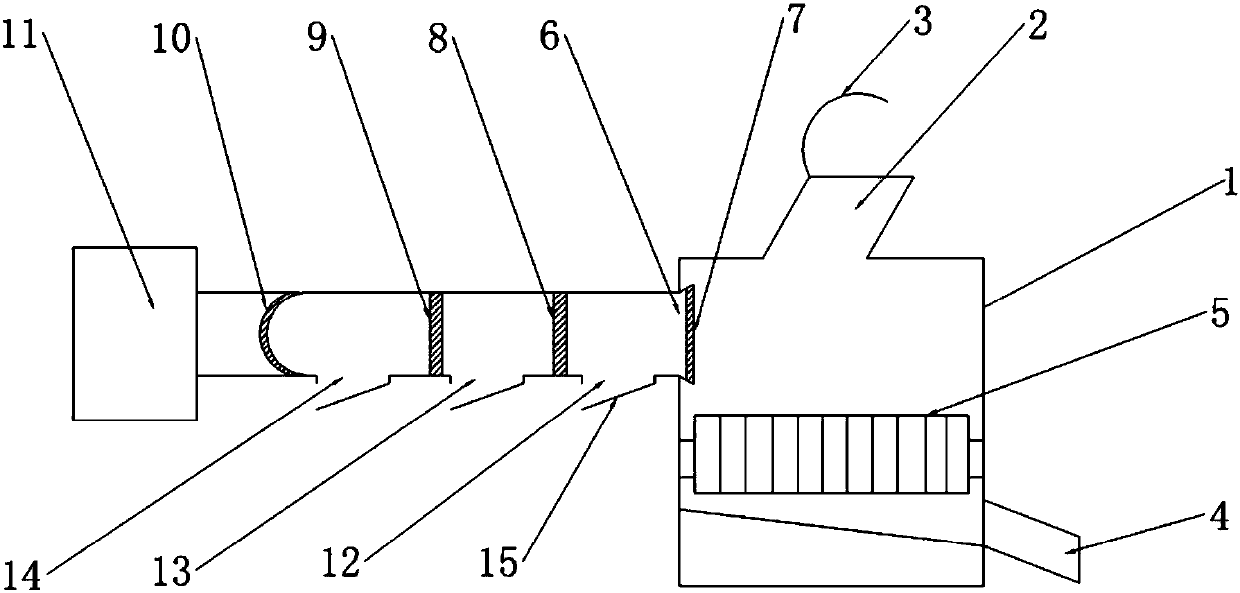

[0015] The reference signs in the drawings of the specification include: body 1, feed inlet 2, arc-shaped dustproof plate 3, discharge outlet 4, crushing mechanism 5, dust removal port 6, first screen 7, second screen 8 , The third screen 9, the dust bag 10, the exhaust fan 11, the first collection port 12, the second collection port 13, the third collection port 14, the cover plate 15.

[0016] Such as figure 1 As shown, the present invention provides an aluminum ore crusher, comprising a fuselage 1, the fuselage 1 is provided with a feed port 2 and a discharge port 4, and the feed port 2 is connected with an arc-shaped dustproof plate 3 by bolts . The fuselage 1 is provided with a crushing mechanism 5 for crushing aluminum ore. The crushing mechanism 5 is an existing conventional design, such as rollers, pendulums and other mechanisms that can crush aluminum ore. The body 1 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com