Dust removing device applied to pipeline

A technology of a dust removal device and a pipeline, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of the danger of burning, the reduction of dust removal efficiency, the intensification of eddy current, etc., and the effect of simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

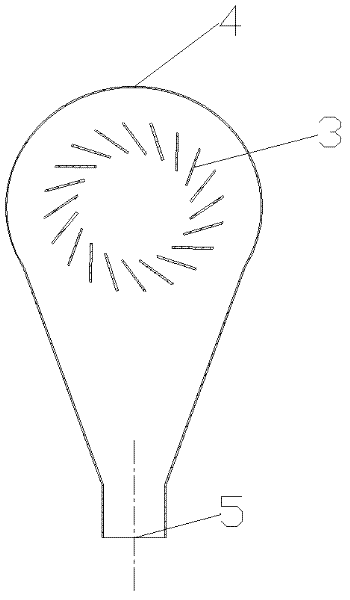

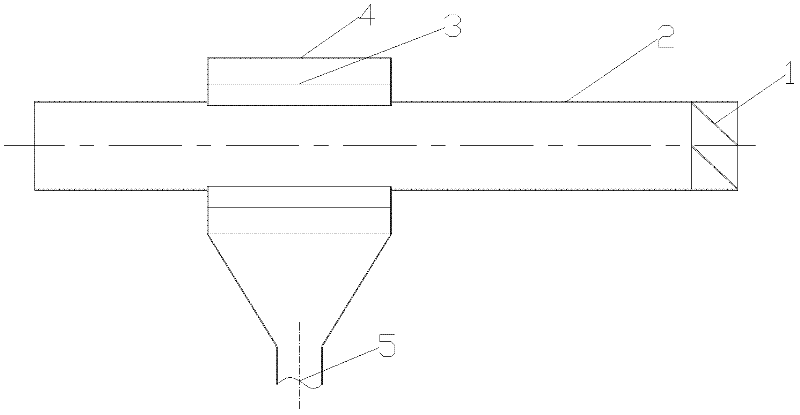

[0045] Embodiment 1: As shown in the figure, a dust removal device used on a pipeline uses the guide fins of the guide part 1 installed inside the pipeline conduit 2 to make the air flow rotate and move the dust to the pipe wall. Dust enters the gap between the gas-solid separation fin 3 and the housing 4 through the action of the gas-solid separation fin 3 of the dust removal part, flows downward under the action of gravity, and is discharged out of the system through the lower ash fall pipe 5 .

Embodiment 2

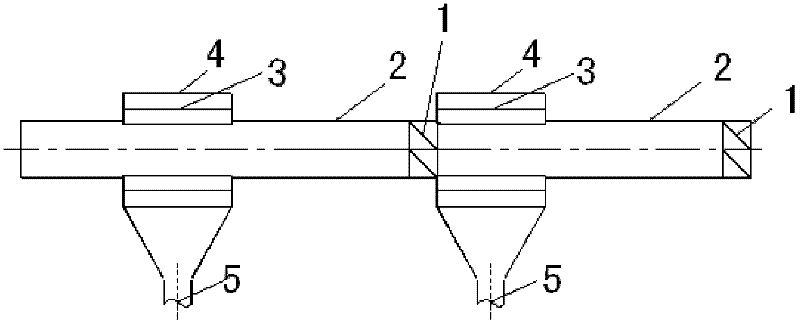

[0046] Embodiment 2: As shown in the figure, a dust removal device used on a pipeline uses a guide member 1 to rotate the fluid, and the dust-laden gas (liquid) enters the dust removal part through the conduit 2 and under the action of the gas-solid separation fin 3, Dust (liquid droplets) enters the shell 4 through the gap of the gas-solid separation fin 3, enters the ash falling pipe 5 under the action of gravity, and is discharged out of the system to realize dust removal in the pipeline.

[0047] The front and rear of the dust removal device are connected with pipes or conduits 2, which are part of the gas or liquid delivery pipeline.

[0048] The dedusting device can be used in pipelines conveying dusty gas or liquid containing solid particles.

[0049] The container connected to the ash fall pipe 5 at the lower part can be equipment under normal pressure or with pressure, but it must be ensured that the pipeline connected to the dust removal device is a sealed system, an...

Embodiment 3

[0052] A dust removal device used on pipelines. The structure of the guide part 1 of the dust removal device is a plate-shaped structural member that forms a certain angle with the radial section of the duct 2, and is fixed on the inner wall of the duct 2 by welding, inlaying or clamping;

[0053] The structure of the gas-solid separation fin 3 is a rectangular plate 6 according to Figure 8 The layout of the schematic diagram, there is an auxiliary line 7 of a virtual circle (just to illustrate the structure, in fact there is no real object), at the junction of the rectangular plate 6 and the auxiliary line 7, the extension line of the rectangular plate 6 at the joint is in the same shape as the radius line of the virtual circle Distributed at a certain angle a;

[0054] The connection relationship between the shell 4 and the gas-solid separation fin 3 is fixed on the side wall of the shell 4 by means of welding, inlaying or clamping;

[0055] The connection relationship betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com