Equipment for removing nano-grade dust in gas and dust removing method of equipment

A nano-scale, dust-based technology, which is applied to the equipment for removing nano-scale dust in the gas and its dust removal field, can solve the problems of easy dust accumulation on the surface of the positive electrode, easy deformation of the negative electrode, etc., to avoid abnormal discharge, easy to clean, and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

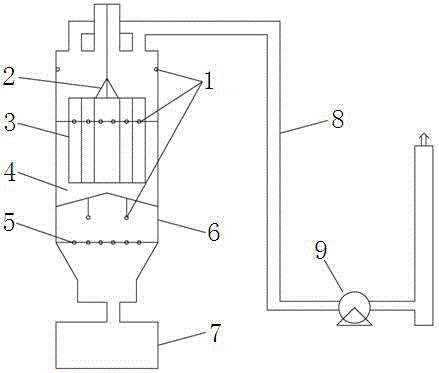

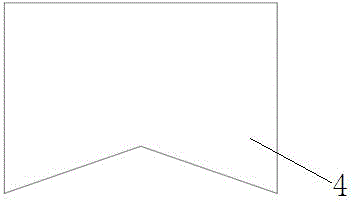

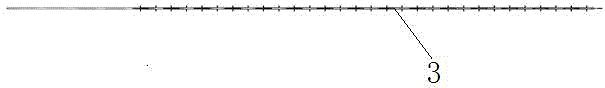

[0038] Refer to attached Figure 1~5 , a device for removing nano-scale dust in gas includes a plate-type positive electrode, a tube-type negative electrode, a spray device 1, an air distribution device 5, a casing 6, a buffer tank 7, an exhaust pipe 8 and an induced draft fan 9. A plate-type positive electrode mounting bracket and a tube-type negative electrode mounting bracket are installed in the shell 6. A plate-type positive electrode 4 is installed on the plate-type positive electrode mounting bracket, and a tube-type negative electrode 3 is installed on the tube-type negative electrode mounting bracket. The tube-type negative electrode 3 is located between the plate-type positive electrode 4 between.

[0039]The sprinkler device 1 includes water pipes and sprinkler heads. The water pipes are distributed in the upper, middle and lower parts of the casing. The sprinkler heads are evenly distributed on the water pipes. On the positive electrode and the tubular negative el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com