Grid type transverse air-intake turbulent flow type electric dust remover

An electrostatic precipitator, horizontal technology, applied in the field of grid-type horizontal air inlet turbulent-flow electrostatic precipitator, can solve the problems of poor rapping effect, large area occupied by the electrostatic precipitator, poor overload capacity, etc., and achieves The effect of prolonging the movement distance and running time, stabilizing the dust content of the exhaust gas, and high absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

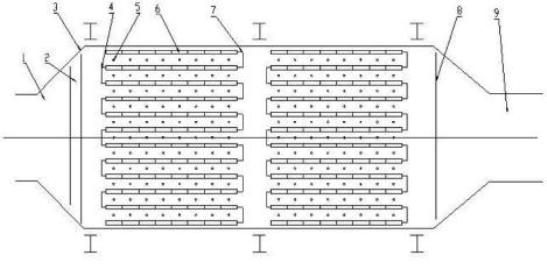

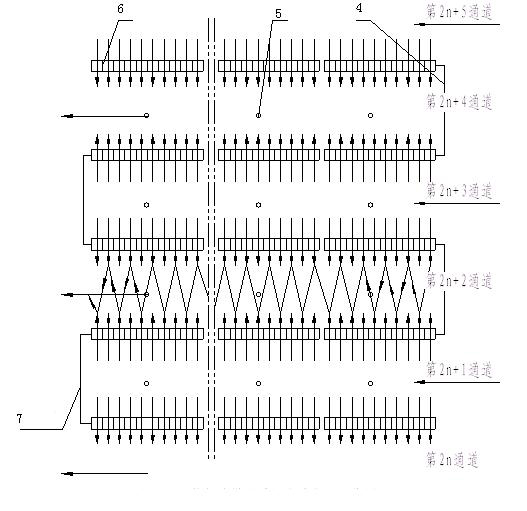

[0025] The grid-type transverse air inlet turbulent flow electrostatic precipitator includes a dust removal device and a vibrator. The dust removal device uses the horizontal turbulent air inlet grille 6 as the anode plate, and the transverse turbulent air inlet grille 6 has multiple rows and is parallel to the The air flow is set, and the cathode line 5 and the gap as the flue gas passage are arranged between two adjacent pieces of each row of transverse turbulent flow inlet grilles 6, and the front end of the flue gas passage formed by each row of transverse turbulent flow inlet grilles 6 The front sealing plate 4 is arranged at intervals to form a high-voltage electric field outlet channel, and the rear sealing plate 7 is arranged at intervals to form a high-voltage electric field inlet channel, and the high-voltage electric field outlet channel is adjacent to the high-voltage electric field inlet channel.

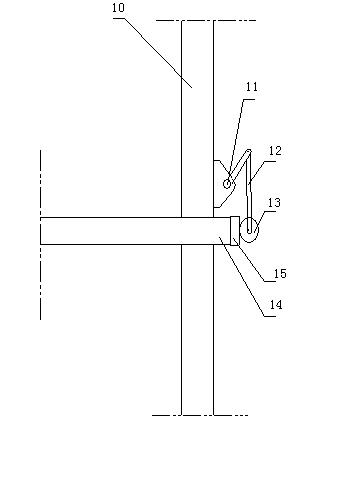

[0026] The cathode wire 5 is fixed on the cathode frame 14. The cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com