Water filtering and dust removing device of dust collector

A technology of dust removal device and water filtration, applied in suction filters and other directions, can solve the problems of not being able to block or secondary filtration, affecting filtration quality, and discharging into the atmosphere, so as to prevent the reduction of dust removal efficiency, improve filtration quality, and reduce height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

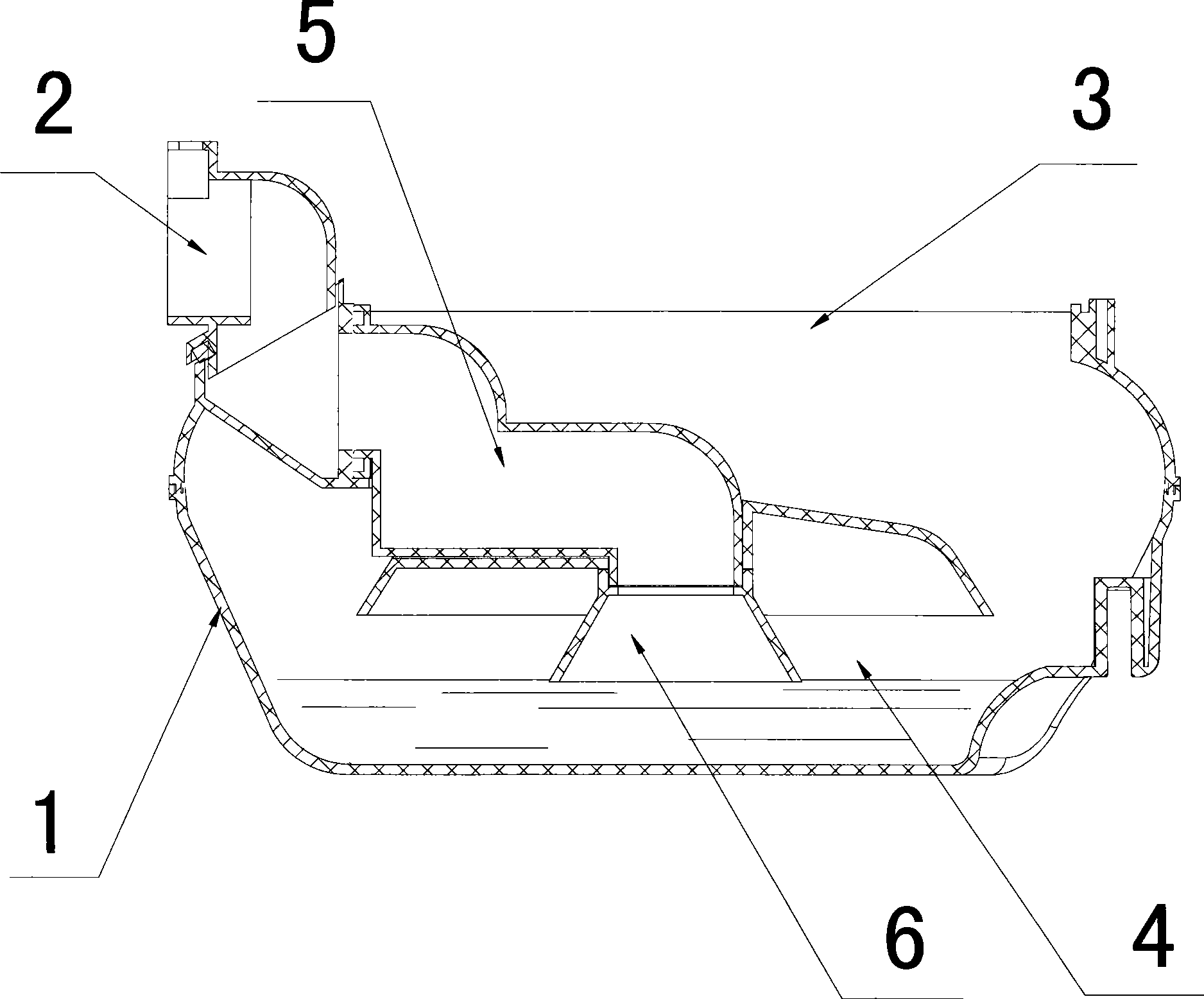

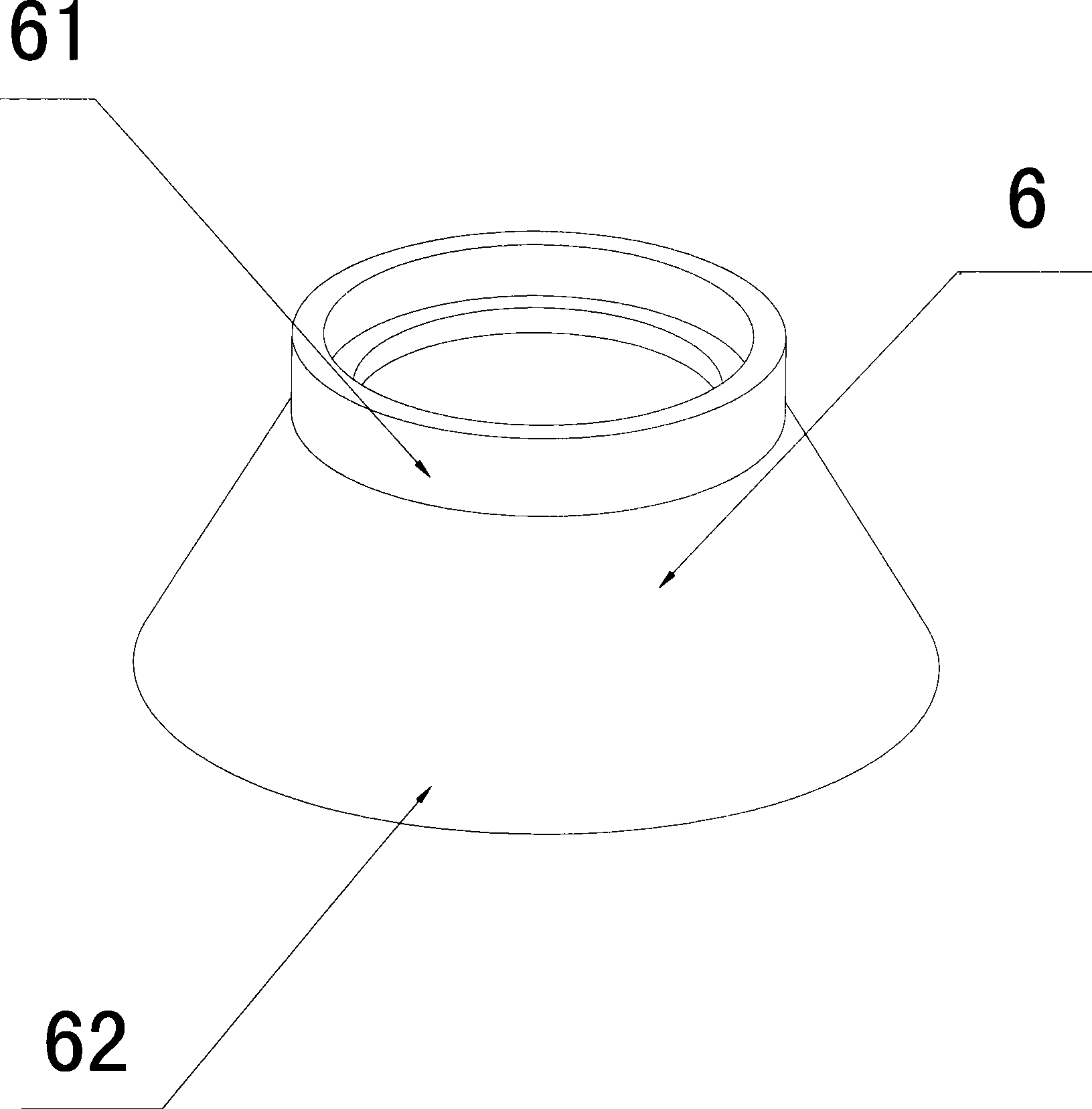

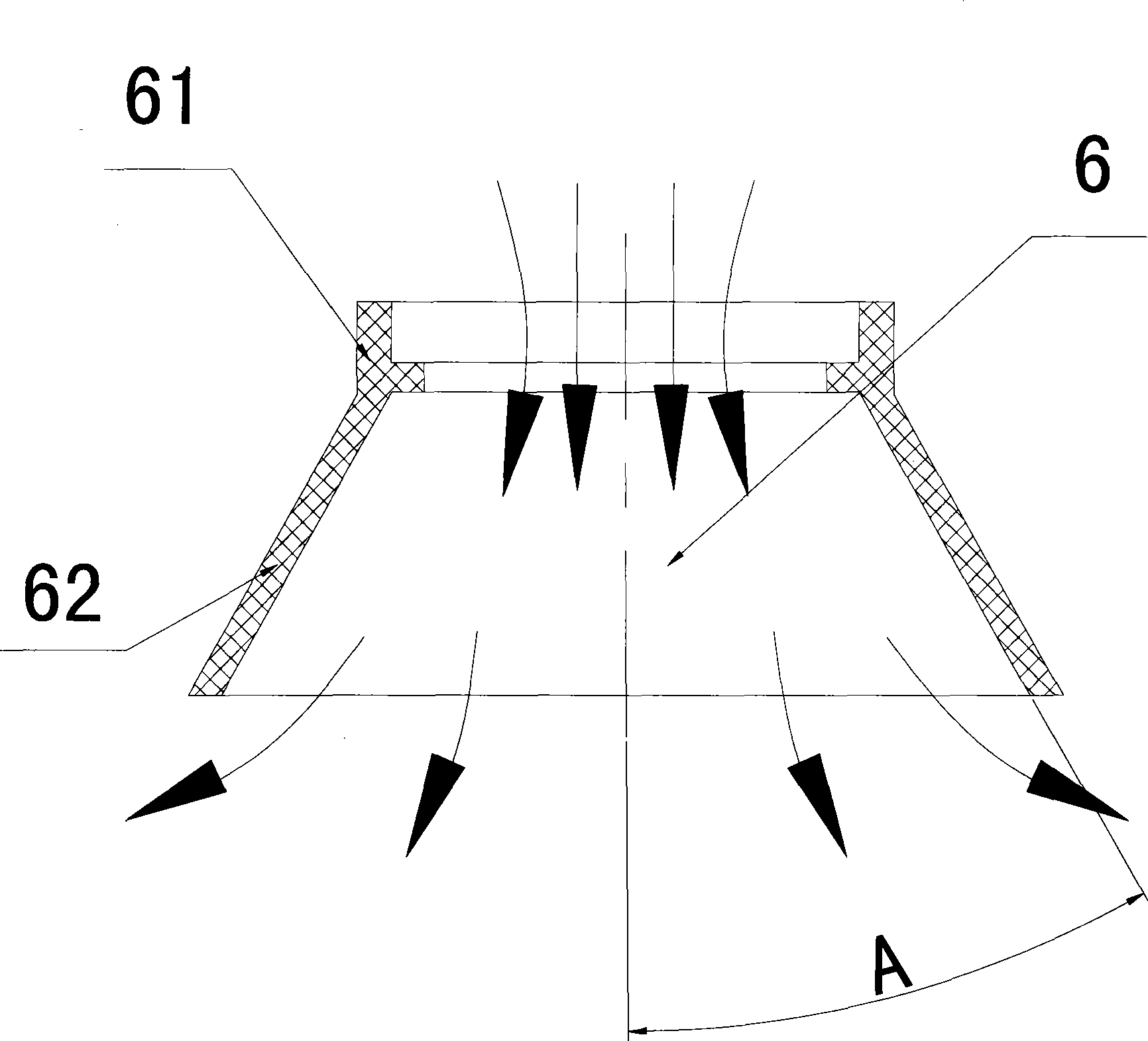

[0036] Example 1: Combining figure 1 , figure 2 , image 3 Shown is a specific embodiment of the water filtration and dust removal device for a vacuum cleaner of the present invention, which includes a dust cup 1 with an air inlet 2 and an air outlet 3, and the dust cup 1 has a water collection chamber 4 located below and a water collection chamber 4 above the dust cup 1. The water and air separation chamber; the dust cup 1 is also equipped with an air inlet pipe 5 connected to the air inlet 2 at one end, and the other end of the air inlet pipe 5 is located in the water collection chamber 4, which is characterized in that the dust cup 1 further includes A diffusion element 6 with an opening facing downwards, its upstream end 61 is connected to the end of the air inlet pipe 5 , and the downstream end 62 is immersed in the water of the water collection chamber 4 , and the cross-sectional area of the downstream end 62 is greater than that of the upstream end 61 .

[0037] An...

Embodiment 2

[0041] Example 2: Combining Figure 5 , Image 6 , Figure 7 , Figure 8 Shown is the specific embodiment of the water filter vacuum cleaner of the present invention;

[0042] It includes a body 8 equipped with a vacuum motor 7 and a detachable water filter and dust removal device installed at the bottom of the body 8; the body 8 is provided with an air inlet 9 and an air outlet 10 connected with the vacuum motor 7, and the water filter and dust removal device includes A dust cup 1 with an air inlet 2. The dust cup 1 has a water collection chamber 4 located below and a water-gas separation chamber located above the water-gas separation chamber. Above the water-gas separation chamber is the dust cup air outlet 3 and the body 8. The air inlet 9 is connected; the dust cup 1 is also equipped with an air inlet pipe 5 connected to the air inlet 2 at one end, and the other end of the air inlet pipe 5 is located in the water collecting chamber 4 . There are three baffles arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com