Hydraulic high-performance concrete with high durability as well as preparation process and preparation device thereof

A technology of high-performance concrete and preparation device, applied in the field of concrete, can solve the problems of unfavorable long-term use, unfavorable rapid production, low mixing efficiency of mixing station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as figure 1 Shown, a kind of high-durability hydraulic high-performance concrete, the raw material of this kind of high-durability hydraulic high-performance concrete comprises: 180 parts of fine aggregate, 100 parts of coarse aggregate, 100 parts of cement, 50 parts of water, 35 parts of fly ash, 80 parts of nano beads, 2.5 parts of superfine natural zeolite powder, 10 parts of alumina, 8 parts of silica fume, 4.5 parts of sodium sulfate, 1.3 parts of polymer emulsion, 3.4 parts of diethanolamine, 3.5 parts of sodium hydroxide, 1 part of methyltrichlorosilane, 2.3 parts of air-entraining agent, 4 parts of polyvinyl alcohol, 5.6 parts of mixed fiber, 0.3 part of sodium nitrite, 1.6 parts of polyvinylpyrrolidone and 1.8 parts of water reducing agent.

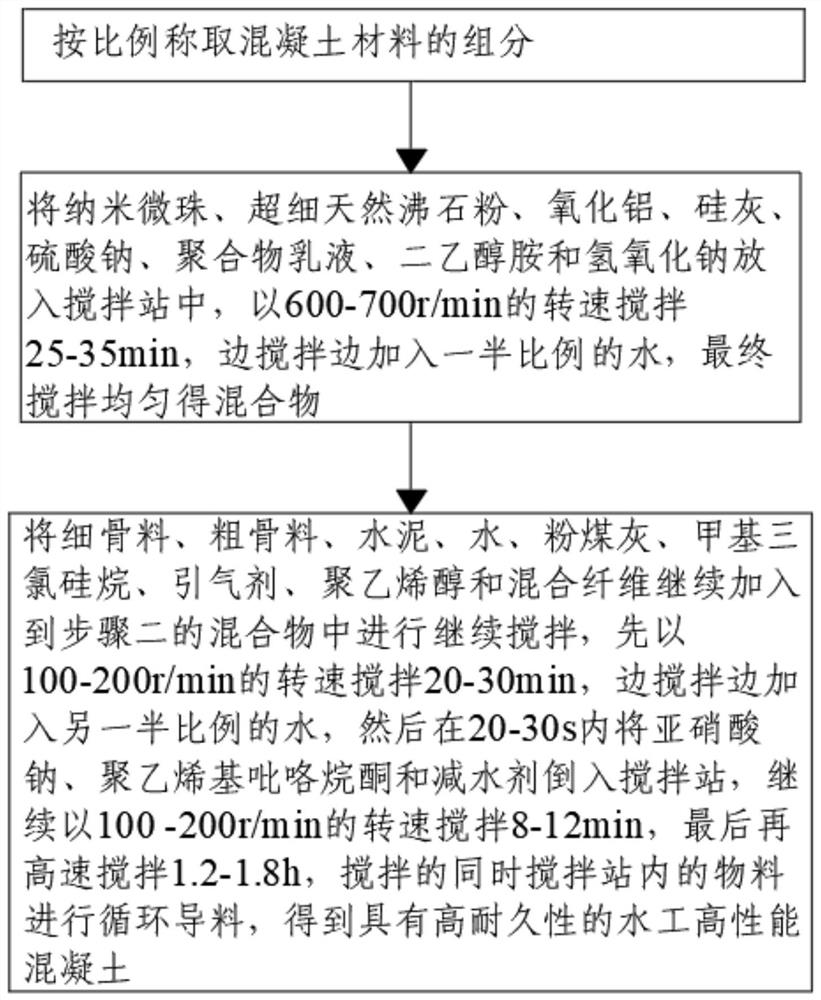

[0047] A preparation process of hydraulic high-performance concrete with high durability, the specific steps are as follows:

[0048] Step 1, taking the components of the concrete material in proportion;

[0049] St...

Embodiment 2

[0052] Such as figure 1 As shown, embodiment 2 is a further improvement to embodiment 1, a kind of high-durability hydraulic high-performance concrete, the raw material of this kind of high-durability hydraulic high-performance concrete includes: fine aggregate 240 parts, 90 parts of coarse aggregate, 200 parts of cement, 120 parts of water, 15 parts of fly ash, 30 parts of nano beads, 3.7 parts of superfine natural zeolite powder, 10 parts of alumina, 5 parts of silica fume, 2.6 parts of sodium sulfate 1.8 parts of polymer emulsion, 5.6 parts of diethanolamine, 1.4 parts of sodium hydroxide, 1.6 parts of methyltrichlorosilane, 3.6 parts of air-entraining agent, 2 parts of polyvinyl alcohol, 3.5 parts of mixed fiber, 1.2 parts of sodium nitrite, 0.5 parts of polyvinylpyrrolidone and 2.3 parts of water reducing agent.

[0053] A preparation process of hydraulic high-performance concrete with high durability, the specific steps are as follows:

[0054] Step 1, taking the compo...

Embodiment 3

[0059] Embodiment 3 is a further improvement to Embodiment 1.

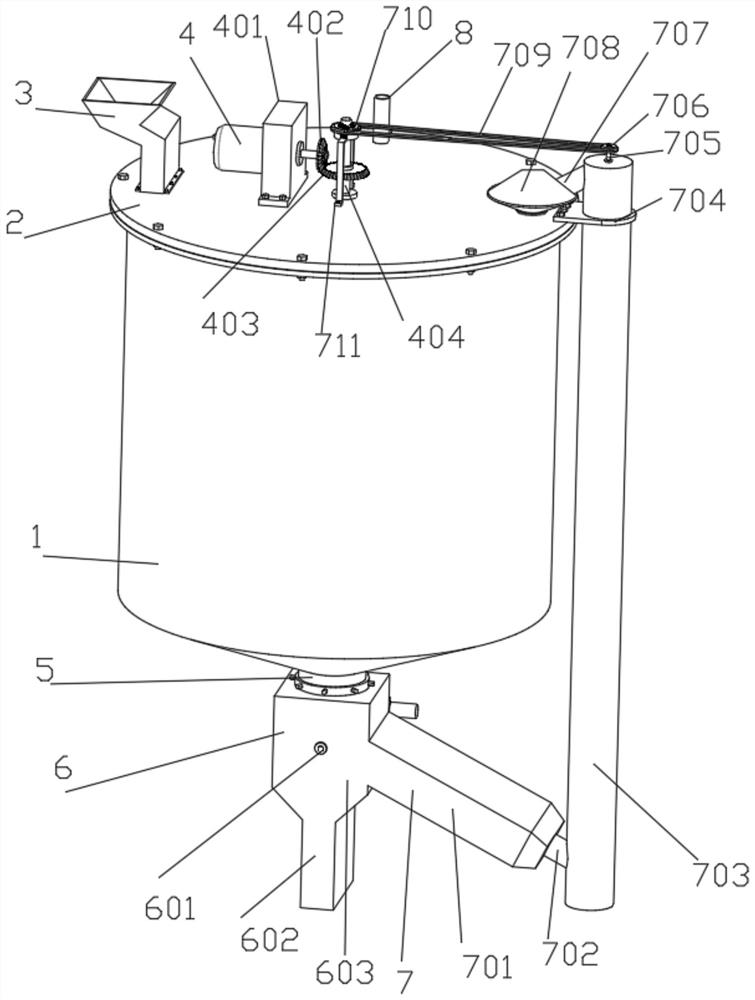

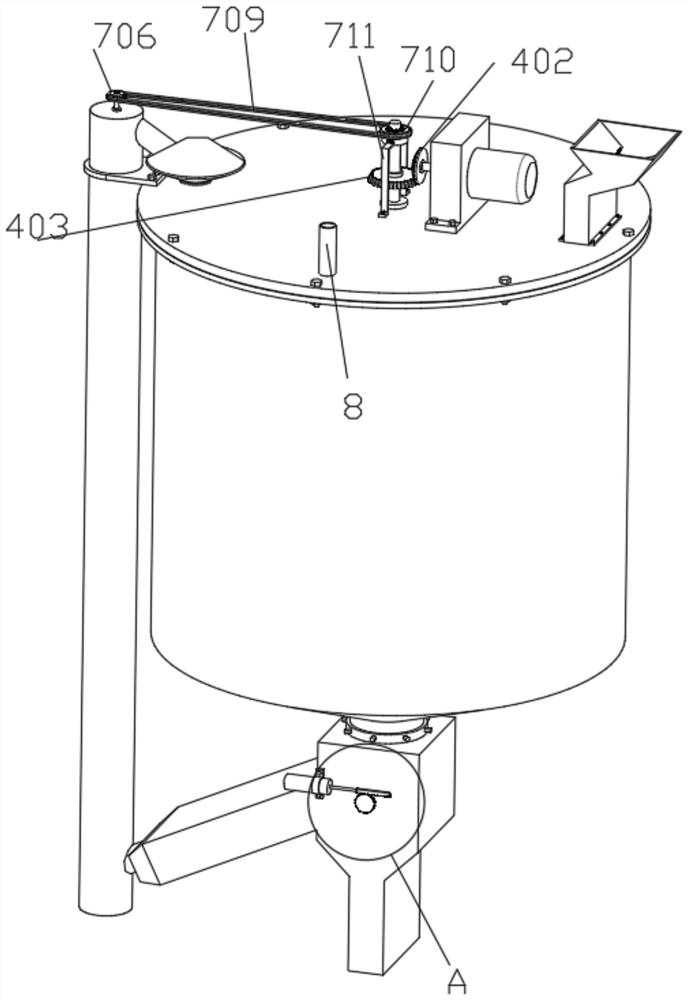

[0060] Such as figure 2 , 3 , 4, 5, 6, 7, 8, 9, 10, 11, a preparation device for hydraulic high-performance concrete with high durability, the preparation device is a mixing station, including a mixing tank 1, a cover plate 2, The straight pipe 5 and the water supply pipe 8, the top of the mixing tank 1 is fixedly connected with the cover plate 2, the top of the cover plate 2 is connected with the feed structure 3, and the feed structure 3 can be dust-proofed, and the feed structure 3 includes the feed Bucket 301, baffle plate 302, round rod 303, lower bump 304, upper bump 305 and inverted L-shaped pipe 306, the feeding hole at the top of cover plate 2 is fixedly connected with inverted L-shaped pipe 306, the inverted L-shaped pipe 306 The top is fixedly connected with a feeding hopper 301, and the bottom of the feeding hopper 301 is symmetrically fixedly connected with an upper bump 305, and between the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com