Washing type grinding dedusting equipment

A kind of dust removal equipment and water washing technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of waste and dust scattered randomly, achieve good dust removal treatment, keep clean and tidy, The effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

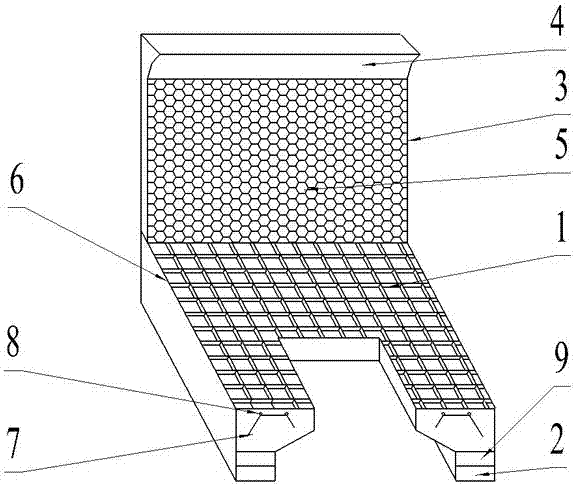

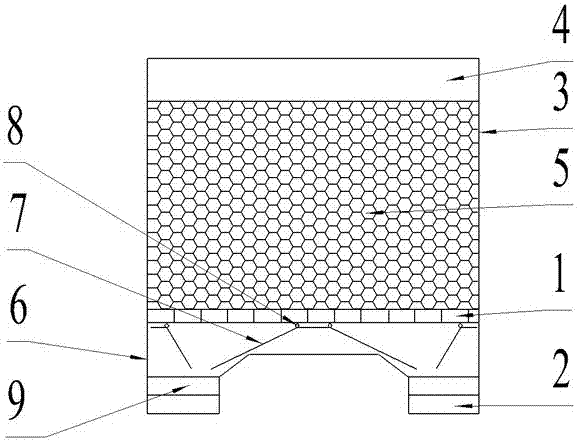

[0025] like figure 1 and figure 2 As shown, a water-washing grinding and dust removal equipment includes a hollowed out grinding platform 1 and a dust removal device. The dust removal device includes a vertical dust removal device located behind the grinding platform 1 and a horizontal dust removal device located below the grinding platform 1. The vertical dust removal device There is a spray system distributed in the horizontal and horizontal dust removal devices, and the bottom of the vertical dust removal device and the horizontal dust removal device have a connected water storage tank 2, and a water pump is arranged on one side of the water storage tank 2, and the water inlet of the water pump is connected to the water storage tank 2 , the water outlet of the water pump is connected with the sprinkler system.

[0026] The grinding platform 1 is a support screen placed above the horizontal dust removal device, and the aperture of the support screen is 2-5 cm.

[0027] Wh...

Embodiment 2

[0031] like figure 1 and figure 2 As shown, the vertical dust removal device includes a first housing 3, a first spray device 4 and a water curtain 5, wherein both sides of the rear end of the grinding platform 1 are fixedly connected to the first housing 3, and the first housing 3 A water curtain 5 is fixed on the vertical surface on one side of the grinding platform 1, and the top of the water curtain 5 is provided with a first spray device 4.

[0032] The water curtain 5 is distributed obliquely, the lower edge of the water curtain 5 is located at the rear end edge of the grinding platform 1, and the upper edge of the water curtain 5 is inclined at 5°-15° toward the grinding platform 1.

[0033] The first spraying device 4 is a spray pipe distributed along the width direction of the water curtain plate 5, and the lower surface of the spray pipe is evenly distributed with two rows of spray holes along the width direction of the water curtain plate 5, and the opening direct...

Embodiment 3

[0039] like figure 1 and figure 2As shown, the horizontal dust removal device includes a second housing 6, a flushing dust removal device, and a particle recovery device 9, wherein a grinding platform 1 is placed on the upper surface of the second housing 6, and the second housing 6 below the grinding platform 1 A flushing and dust removal device and a particle recovery device 9 are sequentially arranged inside from top to bottom, and a water storage tank 2 is located below the particle recovery device 9 .

[0040] The flushing and dedusting device consists of several inclined sliding plates 7 and a second spray device 8 placed on the top of each inclined sliding plate 7 and spraying downwards. The inclined sliding plates 7 cover the entire space under the grinding platform 1, and the adjacent inclined There is a gap of 2-10 cm between the bottoms of the slides 7, and the second spray device 8 on the top of each inclined slide 7 is connected in series through the water pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com