Animal husbandry feed crushing device for

A pulverizing device and animal husbandry technology, applied in the field of animal husbandry, can solve the problems of lack of screening device, inability to pulverize feed, and inability to meet use requirements, and achieve the effect of improving screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

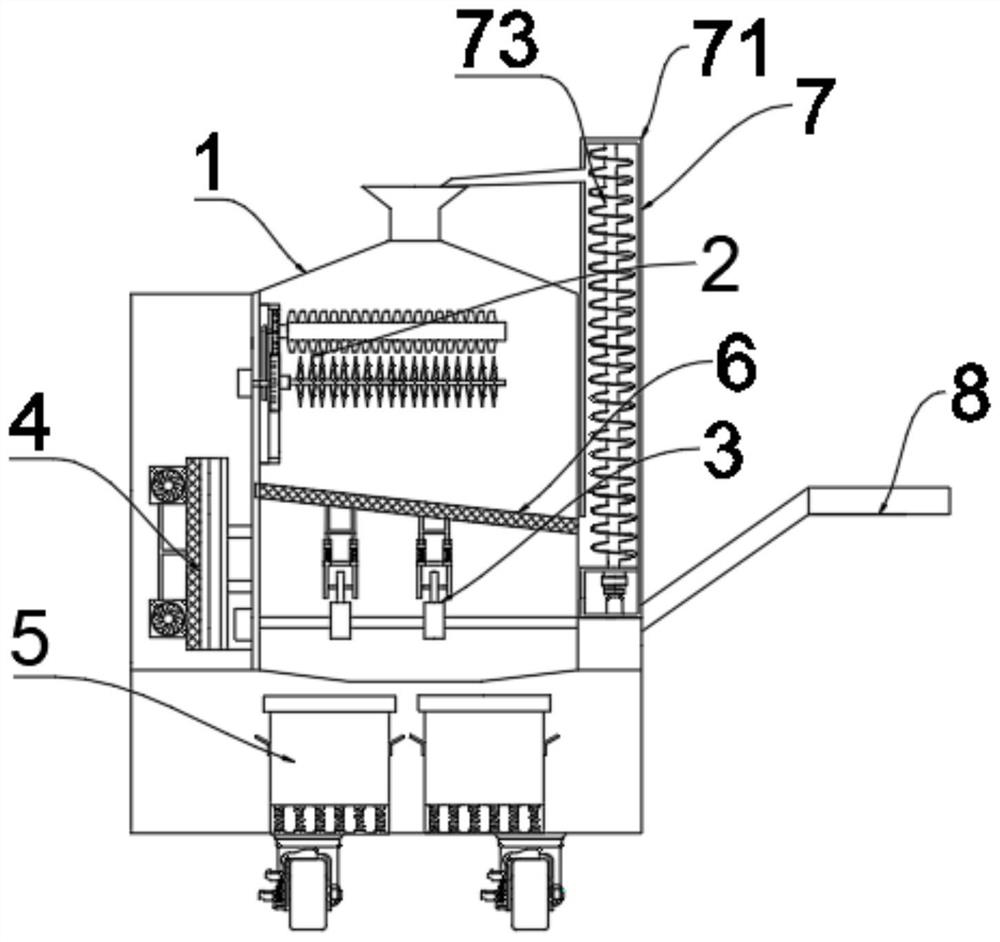

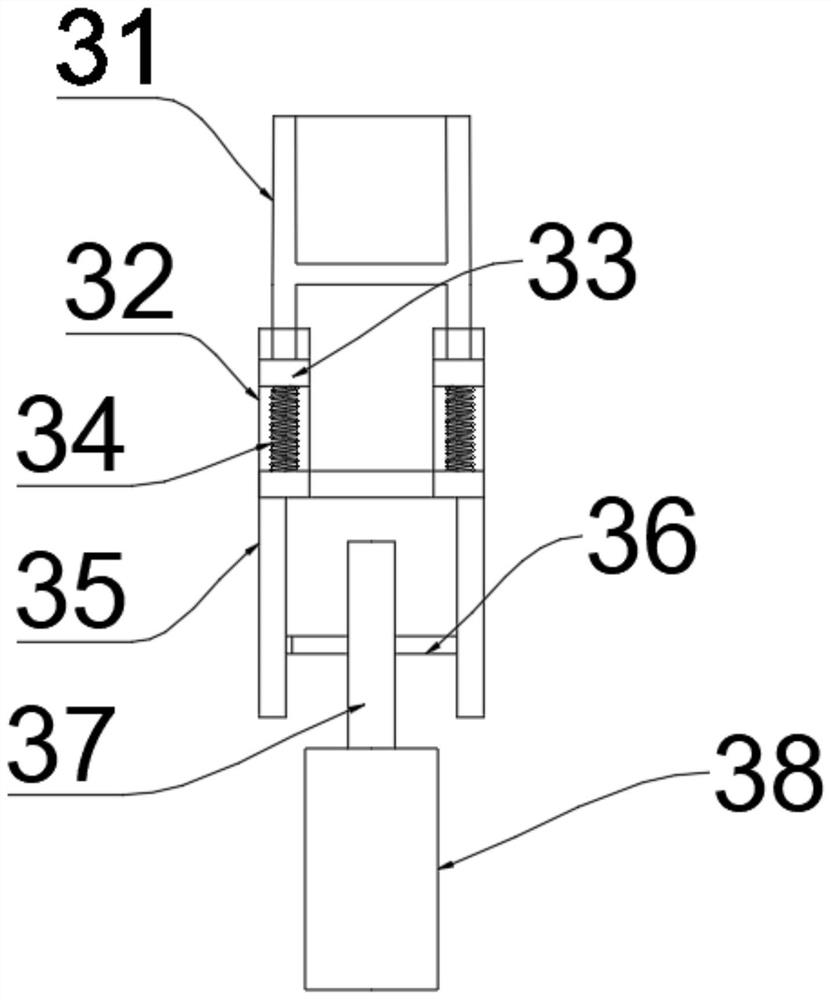

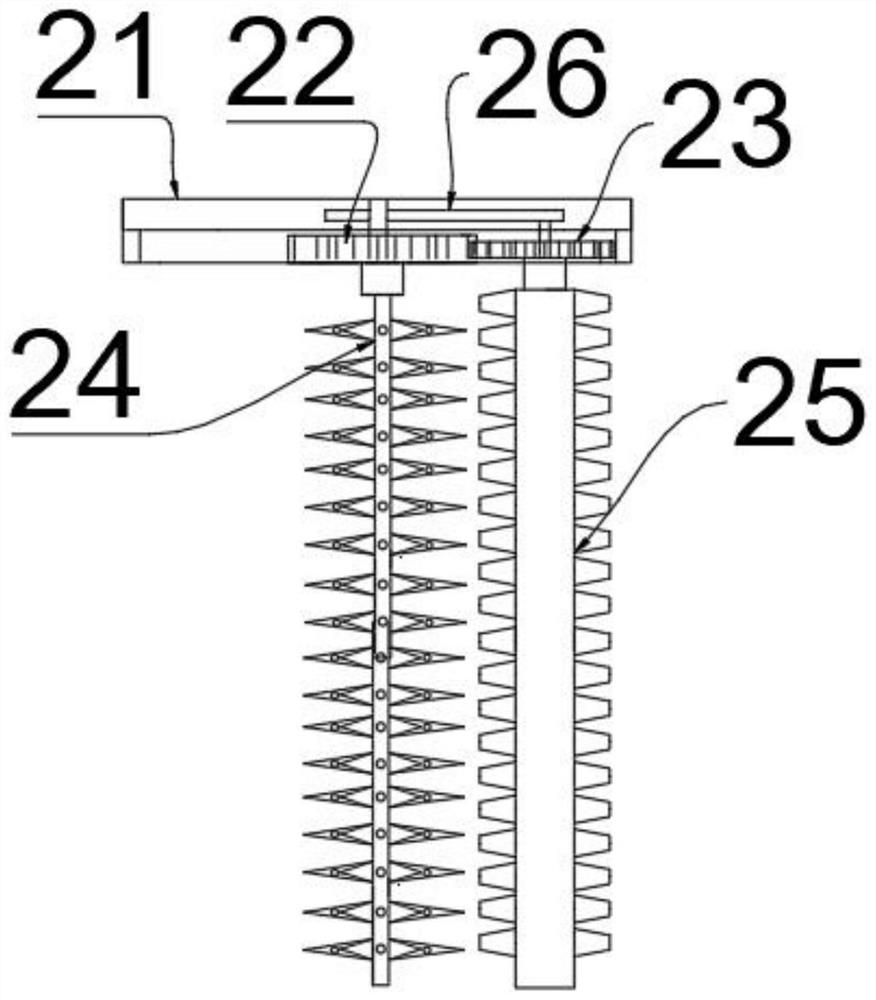

[0028] refer to Figure 1 ~ Figure 4 , a feed crushing device for animal husbandry, comprising a fuselage 1 and a crushing device 2 fixedly installed inside the fuselage 1, a filter plate 6 slidably mounted on the inner wall of the fuselage 1 is arranged below the crushing device 2, and the filter plate 6 Two shaking devices 3 are fixedly installed below the body 1, a return device 7 is fixedly installed on the side of the body 1, a motor is fixedly installed on the side of the body 1, the output end of the motor is connected to a rotating shaft, and the shaking device 3 includes a middle rod, And both sides of the middle rod are symmetrically equipped with contact rods 31, and the bottom of the two contact rods 31 is fixedly installed with a slide block 33, and the side of the slide block 33 is slidably installed with a sliding sleeve 32, and the side of the slide block 33 away from the contact rod 31 is connected. There is a spring 34 fixedly installed on the inner bottom su...

Embodiment 2

[0036] refer to Figure 5 , a feed crushing device for animal husbandry. Compared with Embodiment 1 in this embodiment, the dust removal device 4 includes a dust suction frame 41 fixedly installed on the side of the fuselage 1, and the side of the dust suction frame 41 away from the fuselage 1 is fixedly installed with There are two blowers 42 , and a filter screen 44 is fixedly installed inside the dust suction frame 41 , and two dust removal ports 43 are installed on the side of the dust suction frame 41 close to the fuselage 1 .

[0037] Working principle: when in use, it is convenient to recycle the dust generated in the crushing process by setting the dust removal device 4, collect the dust through the rotation of the fan 42, facilitate the absorption of dust by setting the dust removal port 43, and facilitate the protection of the fan 42 by setting the filter screen 44 Dust handling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com