Composite mixed vanadium dioxide nano powder material and its preparation process

A technology of vanadium dioxide nanometer and powder materials, which is applied in the direction of vanadium oxide, etc., can solve the problems of adverse effects on the environment and the health of operators, complex process steps, and high power of the heating furnace, etc., and is beneficial to environmental protection and operators. health, less equipment investment, and small power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

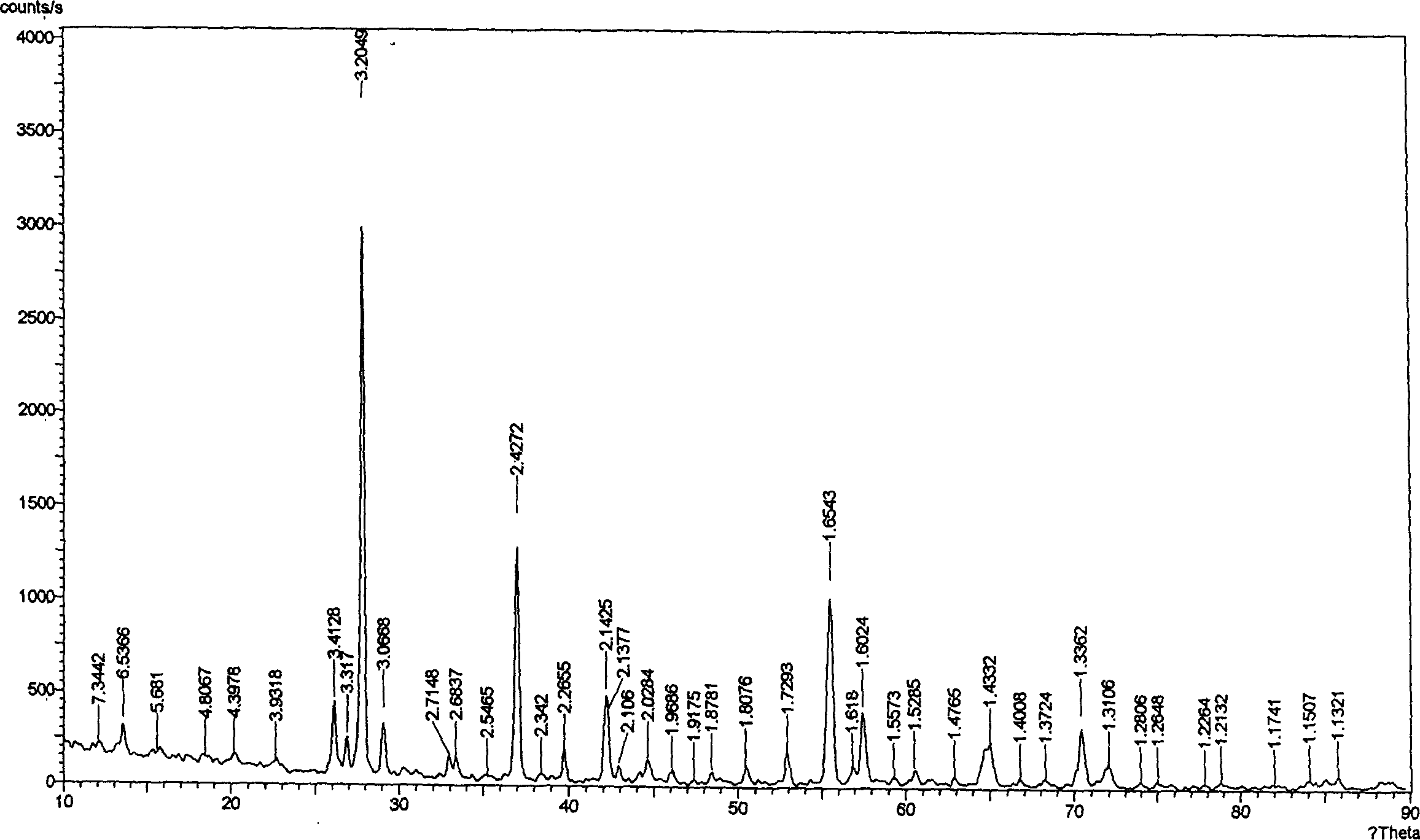

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of Mo-F composite doped vanadium dioxide nanopowder material

[0040] The first group: choose industrial grade V 2 o 5 , V 2 o 5 with MoO 3 , NH 4 The formula of F is calculated by weight percentage: V 2 o 5 98%, MoO 3 1%, NH 4 F 1%; V 2 o 5 The weight ratio with oxalic acid is 1:1.

[0041] (1) Preparation of precursor

[0042] First the ratio of V 2 o 5 with MoO 3 After mixing evenly, put it into a container, heat it to 800°C under normal pressure to become a molten state, then pour the melt into a reaction container filled with water and stir (the amount of water added is not strictly required to disperse V 2 o 5 with MoO 3 melt), and then add the ratio of oxalic acid and NH 4 F and continue to stir until the reduction reaction is completed to obtain a blue liquid without precipitation (the whole process is about 3 hours), after the reduction reaction is completed, the obtained solution is evaporated to dryness at 90 ° C to o...

Embodiment 2

[0066] Embodiment 2: Preparation of W-F composite doped vanadium dioxide nanopowder material

[0067] The first group: choose industrial grade V 2 o 5 , V 2 o 5 with N 5 h 37 W 6 o 24 , NH 4 The formula of F is calculated by weight percentage: V 2 o 5 97%, N 5 h 37 W 6 o 24 1%, NH 4 F 2%; V 2 o 5 The weight ratio with oxalic acid is 1:1

[0068] (1) Preparation of precursor

[0069] First the ratio of V 2 o 5 , N 5 h 37 W 6 o 24 , NH 4 F, oxalic acid and V 2 o 5 Put polyethylene glycol and oxalic acid gross weight 2% into reaction container and add water and stir at normal pressure, 40 ℃ (the adding amount of water is not strictly required, it is advisable to be flooded with the raw material in the reaction container), until reduction reaction Until a blue liquid without precipitation is obtained (the whole process is about 3 hours), after the reduction reaction is completed, the obtained solution is evaporated to dryness at 90° C. to obtain a soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com