Power plant desulfurization wastewater bypass treatment system and method and flue gas treatment system and method

A technology for desulfurization wastewater and power plants, applied in chemical instruments and methods, separation methods, heating water/sewage treatment, etc., can solve the problems of high treatment costs, non-recyclable products, secondary pollution, etc., to avoid secondary pollution, Reduction of processing costs and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

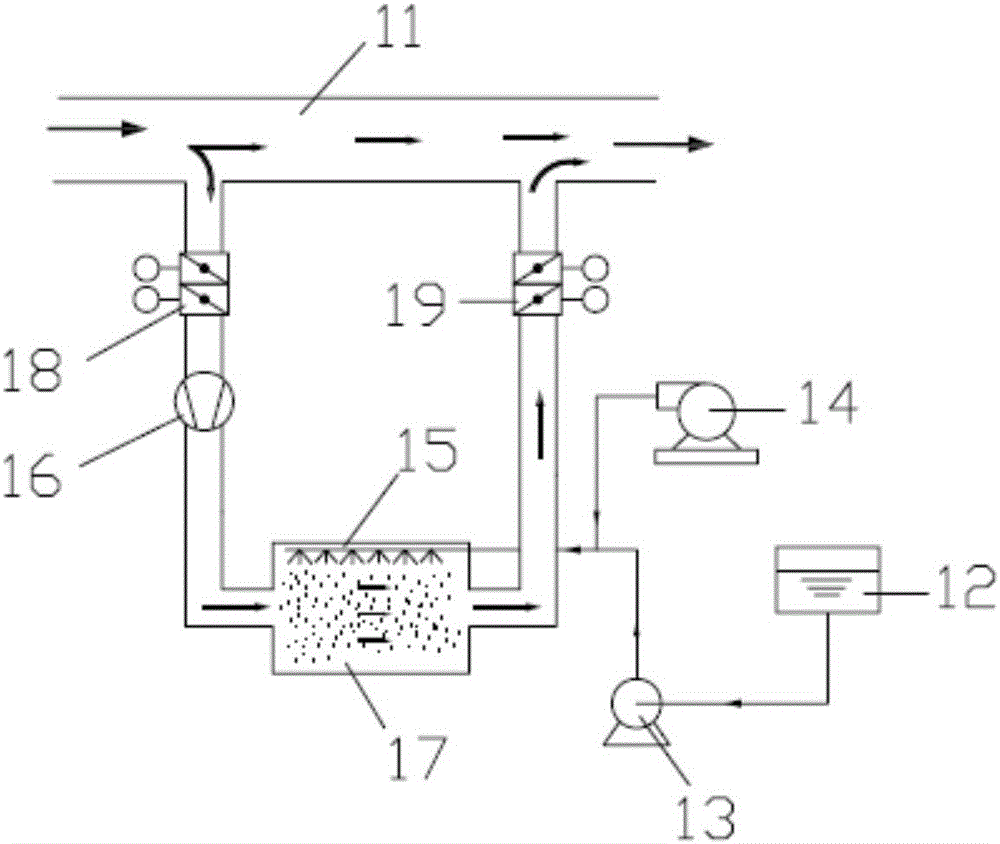

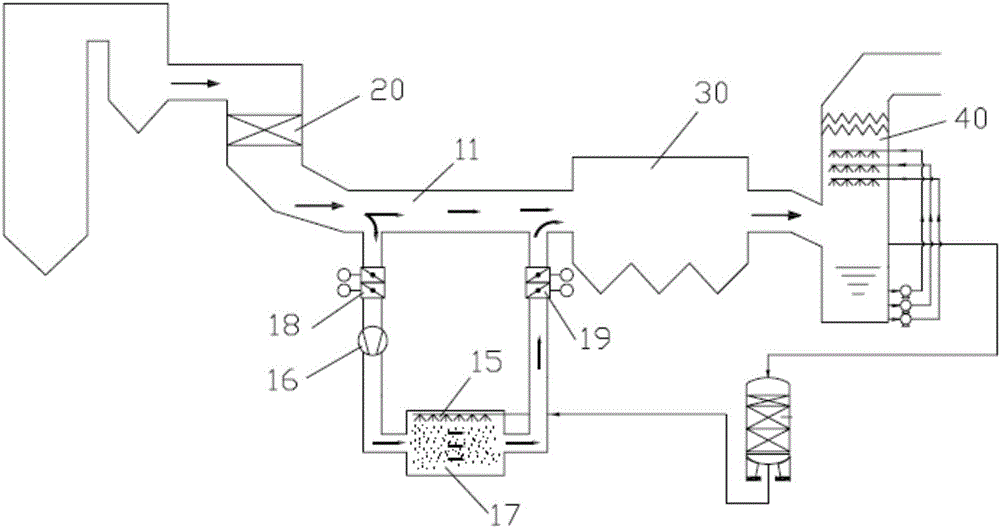

[0050] figure 1 Disclosed is the first embodiment of the system for treating desulfurization wastewater in a power plant bypass of the present invention, including: a main flue 11; a spray water tank 12 for storing desulfurization wastewater; a water pump 13 for extracting desulfurization wastewater in the spray water tank ; An air compressor 14 for atomizing and spraying desulfurization wastewater by compressing air; an atomization spray device 15 for spraying atomized desulfurization wastewater; an induced draft fan 16 for drawing flue gas from the main flue; An evaporator 17 for evaporating atomized desulfurization wastewater; an inlet baffle 18 for controlling the flue gas flux; and an outlet baffle 19 for controlling the flue gas flux.

[0051] The water outlet of the spray water tank 12 is communicated with the water inlet of the water pump 13; the water outlet of the water pump 13 is communicated with the atomizing spray device 15; the outlet of the air compressor 14 is...

Embodiment 2

[0056] Compared with the first embodiment, the improvement of the second embodiment is that the power plant bypass treatment system for desulfurization wastewater disclosed in the second embodiment also includes: a desulfurization wastewater pretreatment device for pretreating the desulfurization wastewater, the desulfurization wastewater pretreatment The treatment device communicates with the spray water tank.

[0057] After the desulfurization wastewater is pretreated by the desulfurization wastewater pretreatment device (such as softening treatment and concentration treatment, etc.), it is convenient for the atomization, spraying and evaporation of the desulfurization wastewater in the subsequent process.

Embodiment 3

[0059] Compared with Embodiment 1, the improvement of Embodiment 3 is that in the system for treating desulfurization wastewater by the power plant disclosed in Embodiment 3, the atomization spraying device is arranged on the top of the evaporator, and the atomized desulfurization wastewater Small droplets are sprayed in the evaporator from top to bottom; the atomization spray device adopts a high-pressure gas-liquid two-phase flow alloy nozzle; and the evaporator is a cylindrical evaporator, and the cylindrical evaporator is arranged horizontally. CFD flow field simulation is the basic setting.

[0060] In this embodiment, the uniformity of the flow field in the evaporator is effectively improved, which further facilitates the complete evaporation of the desulfurization wastewater in the evaporator.

[0061] Of course, in other embodiments, the position of the atomizing spray device in the evaporator can also be adjusted according to needs, such as being arranged on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com