Posture-beautifying cushion and manufacturing method thereof

A manufacturing method and technology for a seat cushion, applied in the field of seat cushion, can solve the problems of easy cracking, short service life, increased production cost, etc., and achieve the effects of increasing softness and wear resistance, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

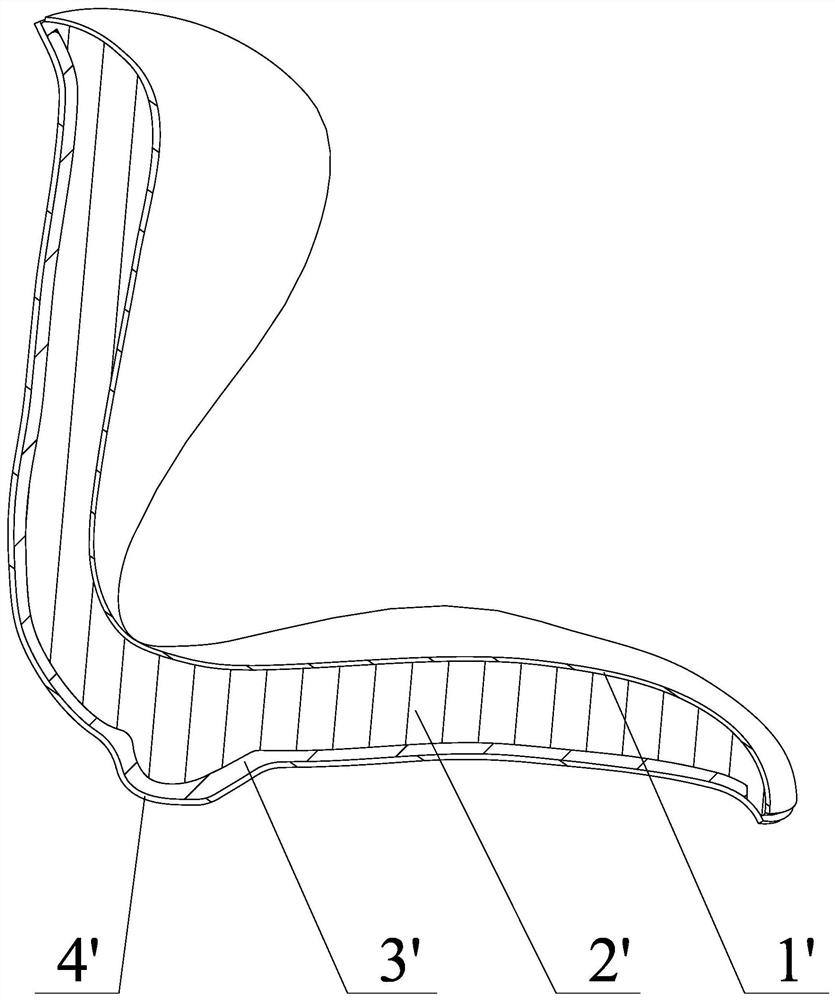

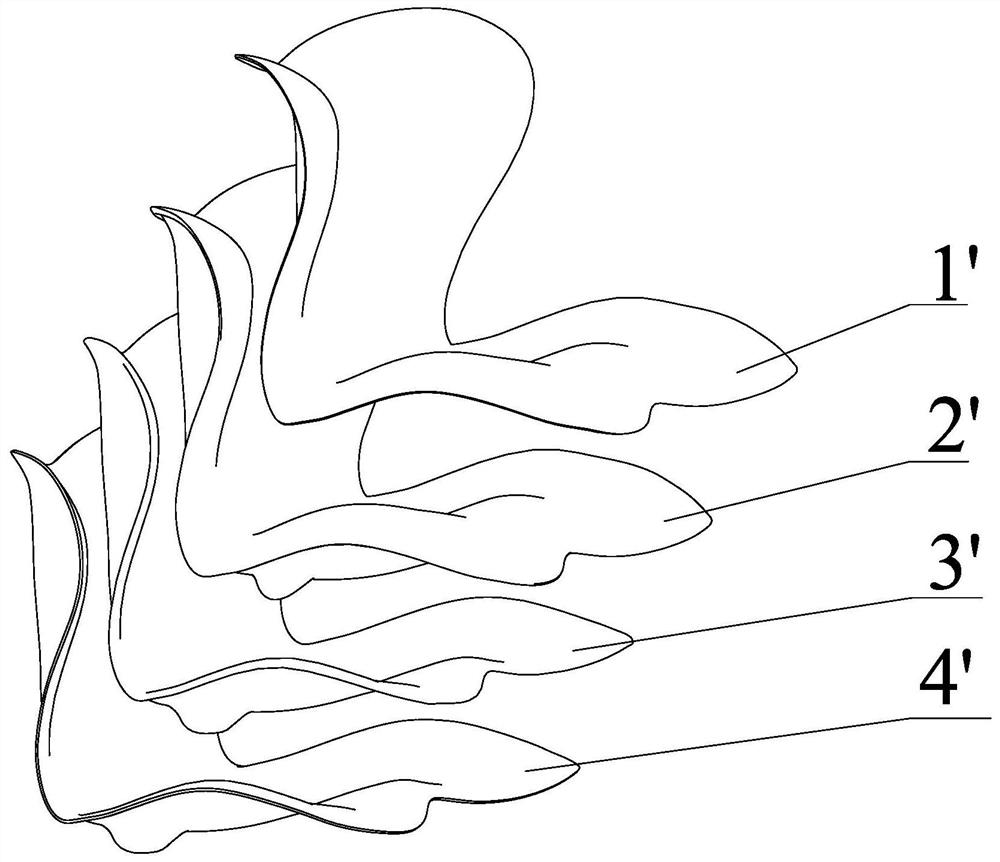

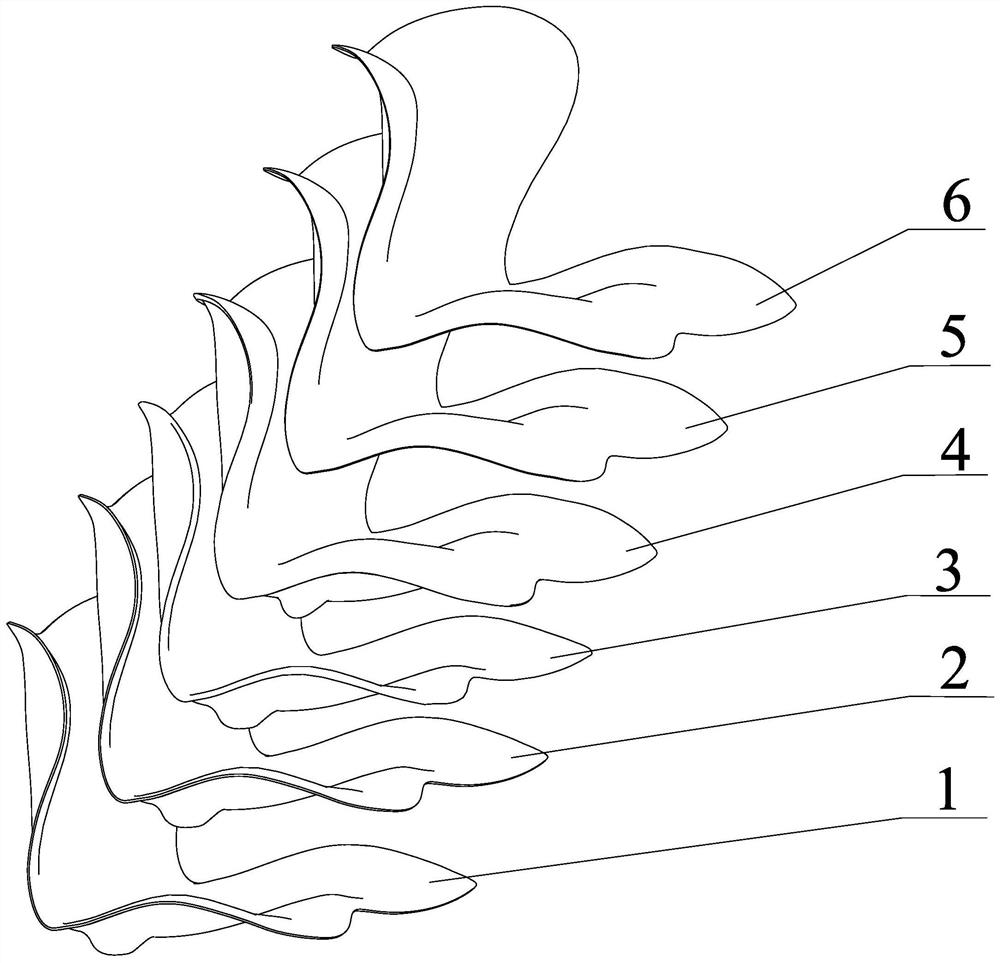

[0039] The invention provides a beautiful posture cushion, such as image 3 As shown, it includes a back sheet 1, a first composite film 2, a plastic shell 3, a molding sponge 4, a second composite film 5 and a front sheet 6, the back sheet 1, the first composite film 2, a plastic shell 3, The forming sponge 4, the second composite film 5 and the front sheet 6 are stacked successively from bottom to top, and the forming sponge 4 is foamed and molded by the foam material; The casing 3 is integrally formed; the back sheet 1 is bonded to the back of the plastic casing 3 .

[0040] In order to improve the user's sense of experience, the present invention adds a first composite film and a second composite film to increase the softness and elasticity of the cushion and prolong the service life of the cushion. The first composite film 2 is compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com