Efficient film laminating machine

A laminator and high-efficiency technology, applied in packaging and other directions, can solve the problems of inability to accurately adjust the speed, reduce the working efficiency of the laminator, reduce the applicability of the laminator, etc., to improve the lamination effect, easy to promote, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

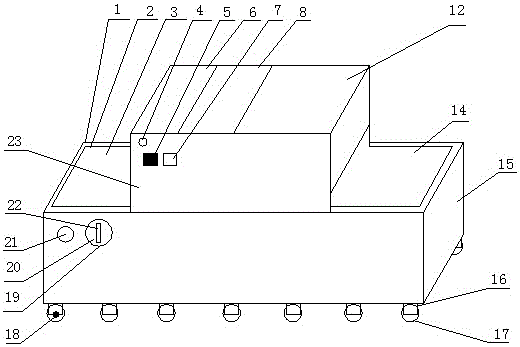

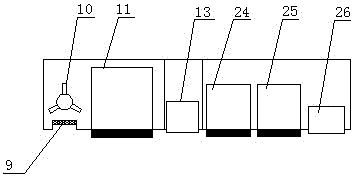

[0018] Example: see Figure 1-2 , a high-efficiency laminating machine of the present invention includes a laminating machine body 1, the laminating machine body 1 includes a working chamber 23 and a machine base 15, the working room 23 is fixedly connected to the machine base 15, and the working room 23 The main opening key 5 is provided on the top, the main opening key 5 is provided with a main key 7 on one side, the power indicator light 4 is provided on the one side of the working room 23, and the film coating chamber 6 is provided on the working room 23, so One side of the film coating chamber 6 is fixedly connected to the drying chamber 8, and one side of the drying chamber 8 is provided with a hot-press chamber 12, and the base 15 is provided with a conveyor belt 3, and the base 15 is provided with a transfer switch 21. One side of the transmission switch 21 is provided with a speed regulator 22, the speed regulator 22 is provided with a speed dial 20, the speed dial 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com