Preparation method for fine grain anisotropy densified neodymium iron boron permanent magnet

An anisotropic and densifying technology, used in the manufacture of inductors/transformers/magnets, permanent magnets, electrical components, etc., can solve the problems of non-anisotropy, low remanence and low maximum magnetic energy product of magnets, and avoid crystal formation. The growth of grains, the effect of ensuring the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

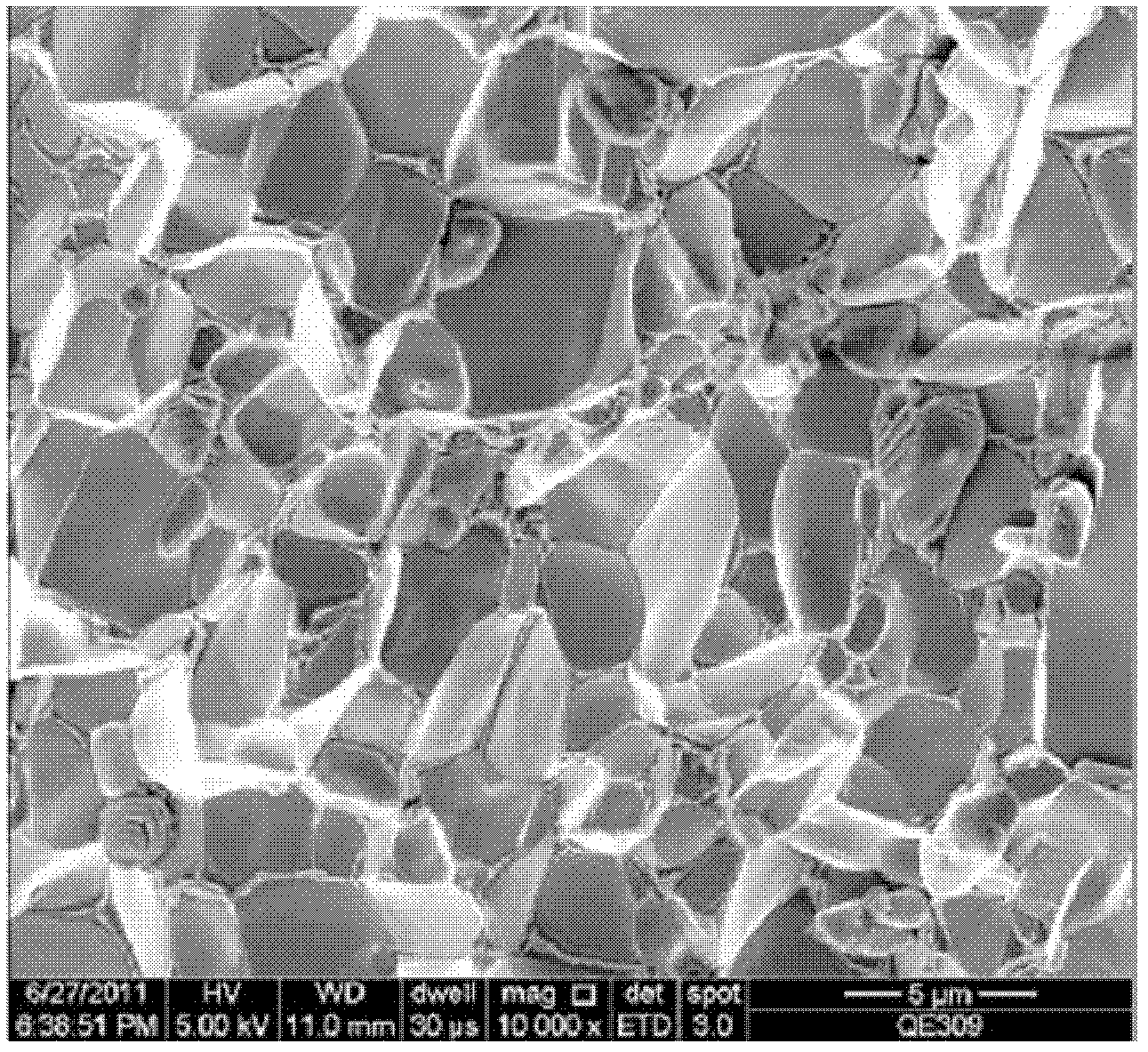

Image

Examples

Embodiment 1

[0022] 1. The alloy whose main alloy composition is Nd27.1Pr6.6Fe65.1B1.2 (mass percentage content) is made into thin slices by using quick-setting thin slice technology;

[0023] 2. Then use the hydrogen crushing and jet milling process to make the quick-setting flakes into a powder with an average particle size of 2.9 μm;

[0024] 3. Orient and press the alloy powder in a 2T magnetic field, and press isostatically for 20 seconds under a pressure of 300MPa;

[0025] 4. Place the green compact in a vacuum furnace and vacuumize to 3×10 -3 After Pa, pre-sinter at 800°C for 2 hours;

[0026] 5. Place the pre-sintered blank in a vacuum hot-press furnace and evacuate to 6×10 -3 After Pa, raise the temperature to 850°C, pressurize 500MPa along the orientation direction of the magnet blank, hold the pressure for 2 minutes, and then cool it out;

[0027] 6. Then heat-treat the hot-pressed blank at 900° C. and 500° C. for 2 hours in vacuum to obtain a final magnet.

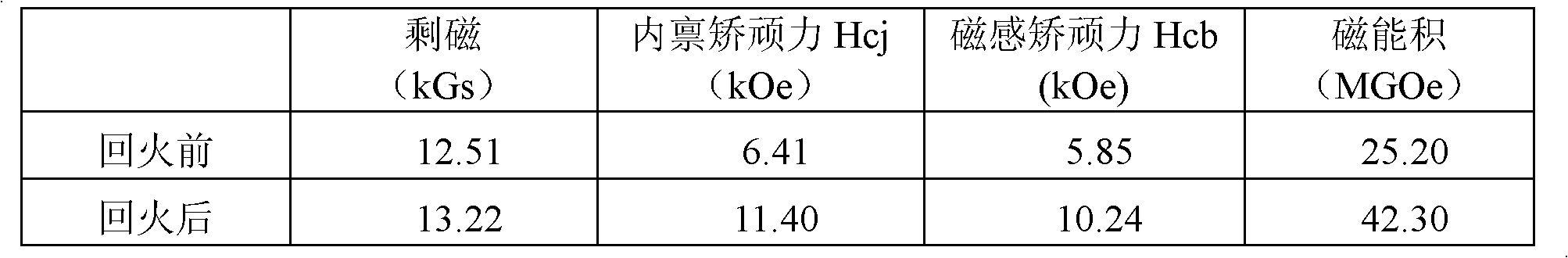

[0028] The mag...

Embodiment 2

[0032] 1. The alloy whose main alloy composition is Nd30.5Fe67.2Co1.0Cu0.2Al0.1B1.0 (mass percentage) is made into thin slices by using quick-setting thin slice technology;

[0033] 2. Then use the hydrogen crushing and jet milling process to make the quick-setting flakes into a powder with an average particle size of 2.7 μm;

[0034] 3. Orient and press the alloy powder in a 2T magnetic field, and press isostatically for 20 seconds under a pressure of 300MPa;

[0035] 4. Place the green compact in a vacuum furnace and vacuumize to 3×10 -3 After Pa, pre-sinter at 900°C for 2 hours;

[0036] 5. Place the pre-sintered blank in a vacuum hot-press furnace and evacuate to 6×10 -3 After Pa, raise the temperature to 830°C, pressurize 300MPa along the orientation direction of the magnet blank, hold the pressure for 2 minutes, then cool and take it out;

[0037] 6. Then heat-treat the hot-pressed blank at 900° C. and 500° C. for 2 hours in vacuum to obtain a final magnet.

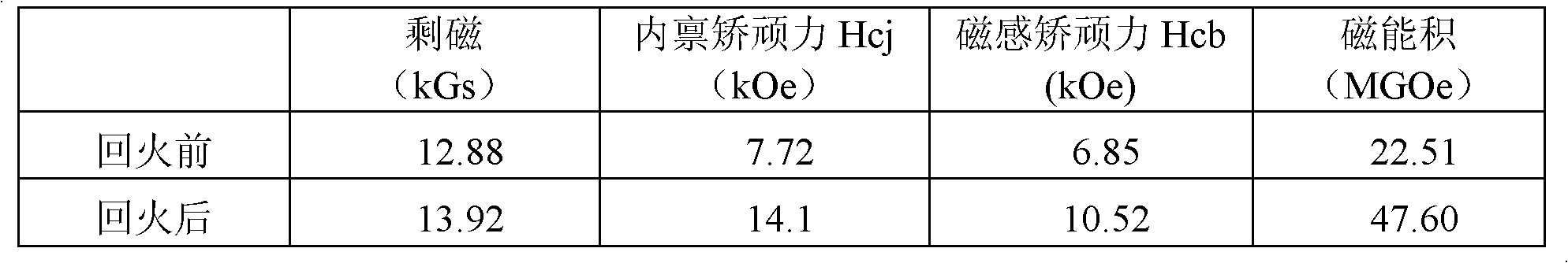

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com