Full-automatic multifunctional mask machine

A multi-functional and fully automatic technology, applied in the direction of clothing, thin material processing, winding strips, etc., can solve the problems of slow production and slow speed of high-standard masks, achieve high degree of automation, convenient use, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

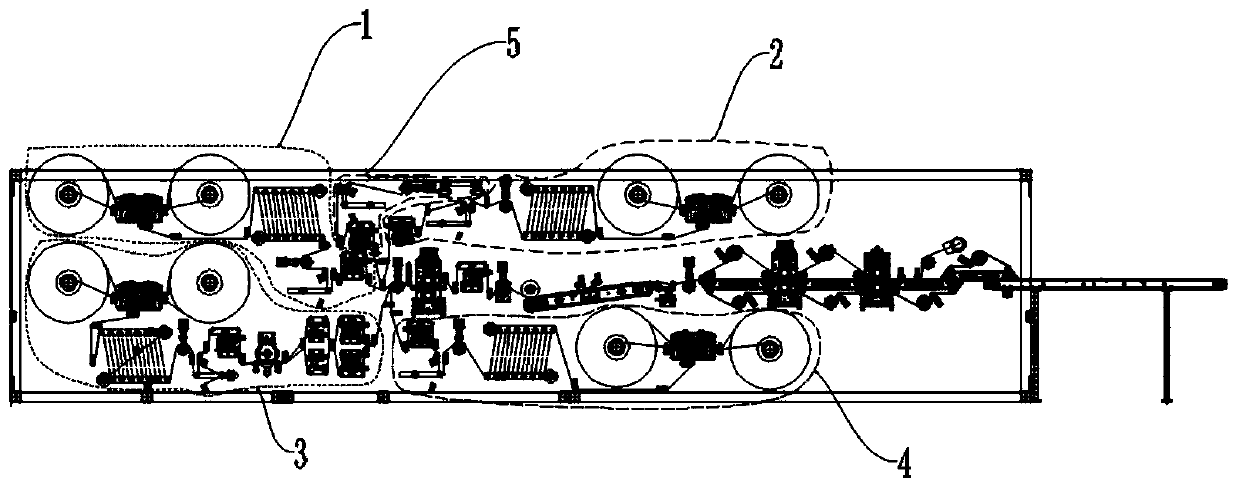

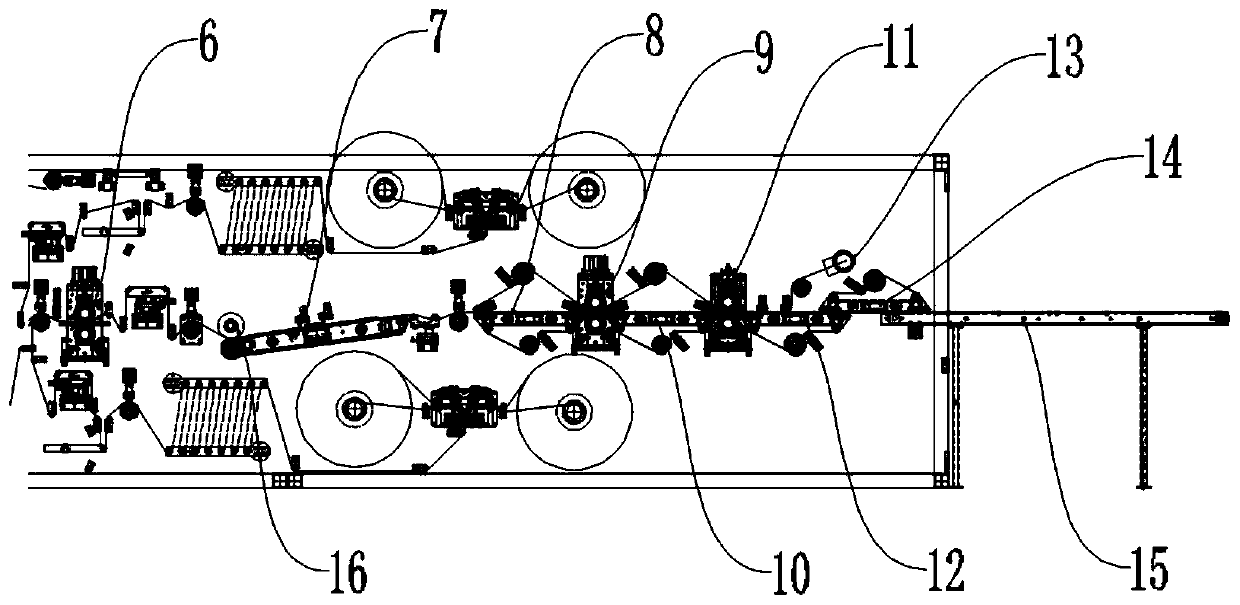

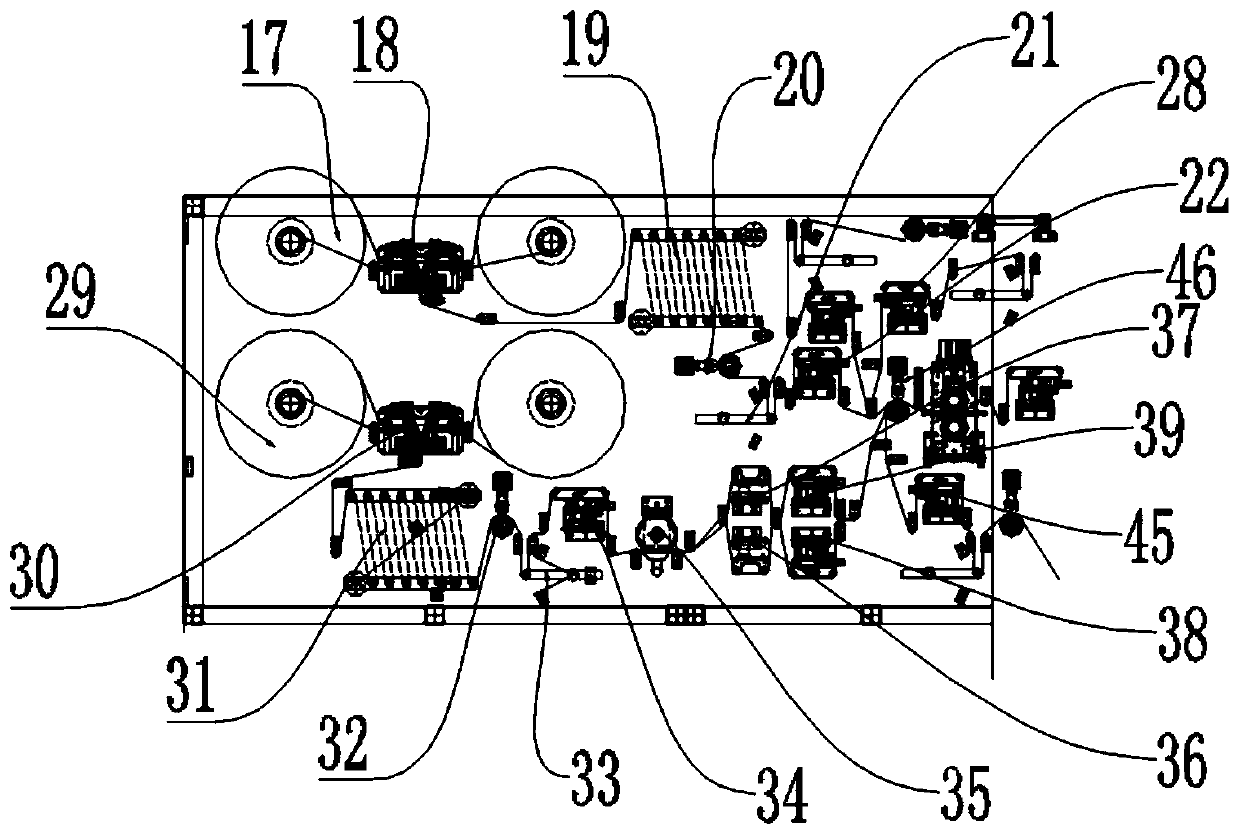

[0045] refer to Figure 1 to Figure 19 A fully automatic multi-functional mask machine shown, including a meltblown cloth conveying mechanism 1, a lining material conveying mechanism 2, an inner layer material conveying mechanism 3, an outer layer material conveying mechanism 4, a spare material conveying mechanism 5, and a leveling mechanism 6. Folding mechanism 7, wind bucket assembly, ultrasonic heat pressing mechanism 9, peripheral cutting mechanism 11, edge material collection mechanism 13 and frame 64, said wind bucket assembly includes wind bucket assembly one 8, wind bucket assembly two 10, wind bucket assembly two Bucket assembly three 12 and wind bucket assembly four 14, wind bucket assembly one 8, wind bucket assembly two 10, wind bucket assembly three 12, and wind bucket assembly four 14 all include bellows 53, drive wheel 54, tension pulley 55, and drive roller 56 , auxiliary wheel combination eight 57 and conveyer belt 58, conveyer belt 58 is arranged around bell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com