A 5D three-dimensional relief effect material and production process

A three-dimensional relief, driving roller technology, applied in synthetic resin layered products, chemical instruments and methods, layered products and other directions, can solve problems such as unfavorable display, unsatisfactory 5D relief three-dimensional effect, etc. Structural strength and tensile properties, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] refer to figure 1 Described, a 5D three-dimensional relief effect material, the 5D three-dimensional relief effect material is composed of the following components by weight: 65 parts of PVC resin, 45 parts of polyurethane, 35 parts of polymethyl methacrylate, 12 parts of phosphite, two parts by weight. 15 parts of glycol dibenzoate, 4 parts of PVC stabilizer, 1 part of non-toxic plasticizer, 1.5 parts of cyclohexyl p-methoxycinnamate, 1.2 parts of 4-methyl-6-methoxycoumarin share.

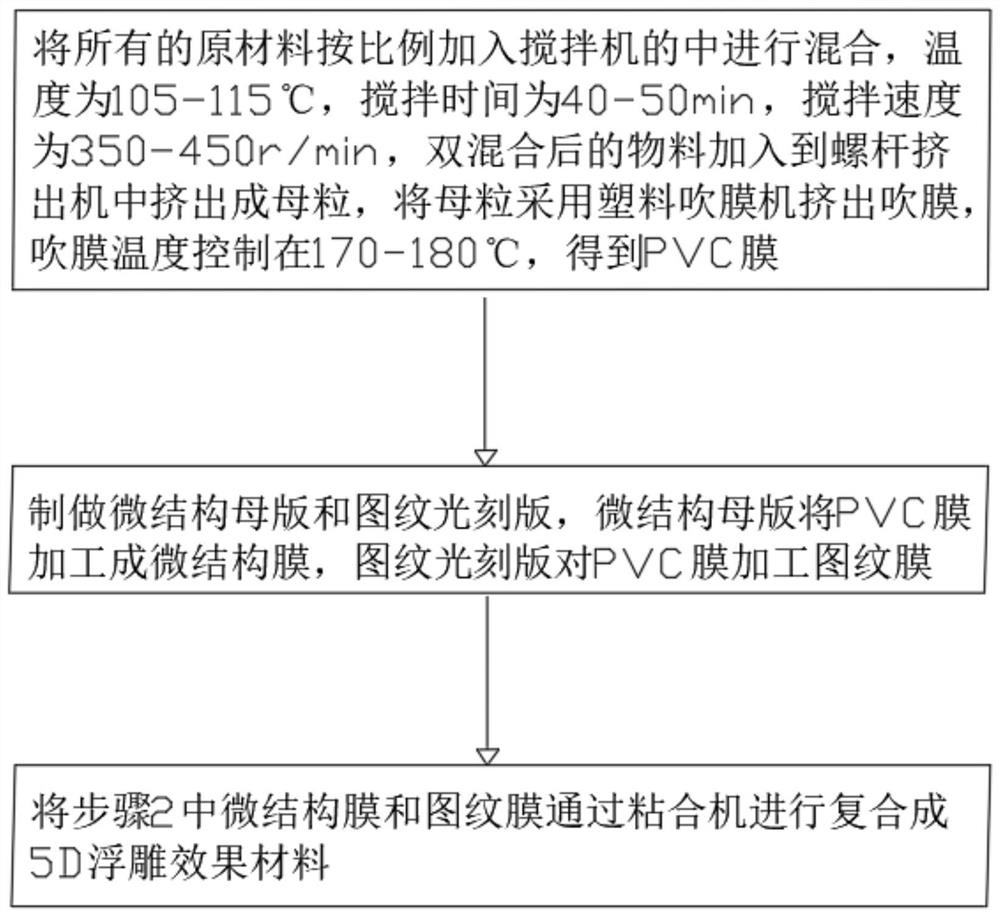

[0042] A production process of a 5D three-dimensional relief effect material, comprising the following steps;

[0043] Step 1: Add all the raw materials in proportion to the mixer for mixing, the temperature is 115°C, the mixing time is 40min, the mixing speed is 450r / min, the double-mixed materials are added to the screw extruder and extruded into masterbatches , the masterbatch is extruded and blown by a plastic film blowing machine, and the blown film temperature is controlled at 170 °...

Embodiment 2

[0047] refer to figure 1 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that a 5D three-dimensional relief effect material is composed of the following components by weight: 82 parts of PVC resin, 35 parts of polyurethane parts, 28 parts of polymethyl methacrylate, 16 parts of phosphite, 5 parts of diethylene glycol dibenzoate, 4 parts of PVC stabilizer, 1 part of non-toxic plasticizer, p-methoxycinnamic acid ring 1.1 parts of hexyl esters, and 1.5 parts of 4-methyl-6-methoxycoumarins.

[0048] A production process of a 5D three-dimensional relief effect material, comprising the following steps;

[0049] Step 1: Add all the raw materials in proportion to the mixer for mixing, the temperature is 105°C, the mixing time is 40min, the mixing speed is 350r / min, the double-mixed materials are added to the screw extruder and extruded into masterbatches , the masterbatch is extruded and blown by a plastic film blowing machine, and the f...

Embodiment 3

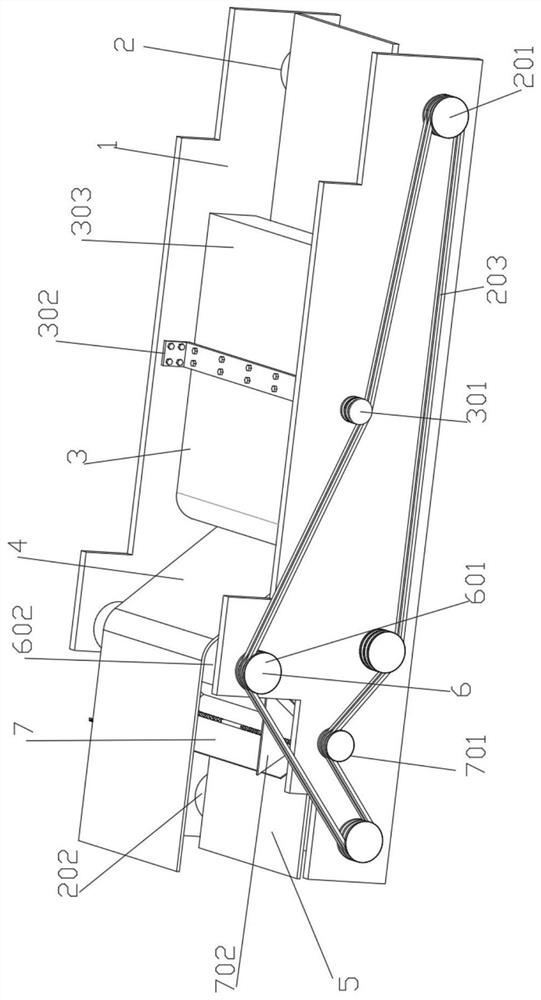

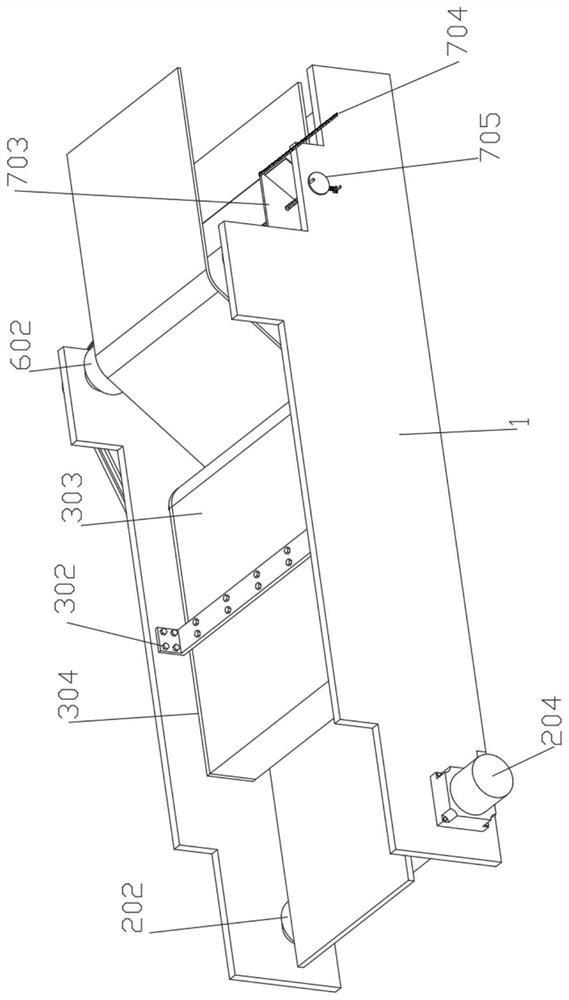

[0054] refer to Figure 2-11 As shown, a device for 5D three-dimensional relief effect material, the device is the bonding machine of step 3, including a support frame 1, a pattern film 4, a microstructure mold 5 and a horizontal plate 8, the horizontal plate 8 is provided with multiple groups, and the horizontal Both ends of the plate 8 are fixedly installed at the bottom of the inner wall of the support frame 1, and the support frame 1 is connected with a first driving structure 2 for driving the movement of the microstructure mold 5. The first driving structure 2 includes a first pulley 201, a first driving roller 202, The belt 203 and the drive motor 204, the drive motor 204 is fixedly installed on the side wall of the support frame 1, the support frame 1 is rotatably connected with the first drive roller 202 through the fixedly connected bearing, and a group of the first drive roller 202 is connected with the drive motor 204. The output end of the first drive roller 202 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com