Automatic wire barrow

A pay-off car, automatic technology, applied in the direction of conveying filamentous materials, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as large space and occupation, and achieve improved cleaning effect, reduced space occupation, and improved convenience. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

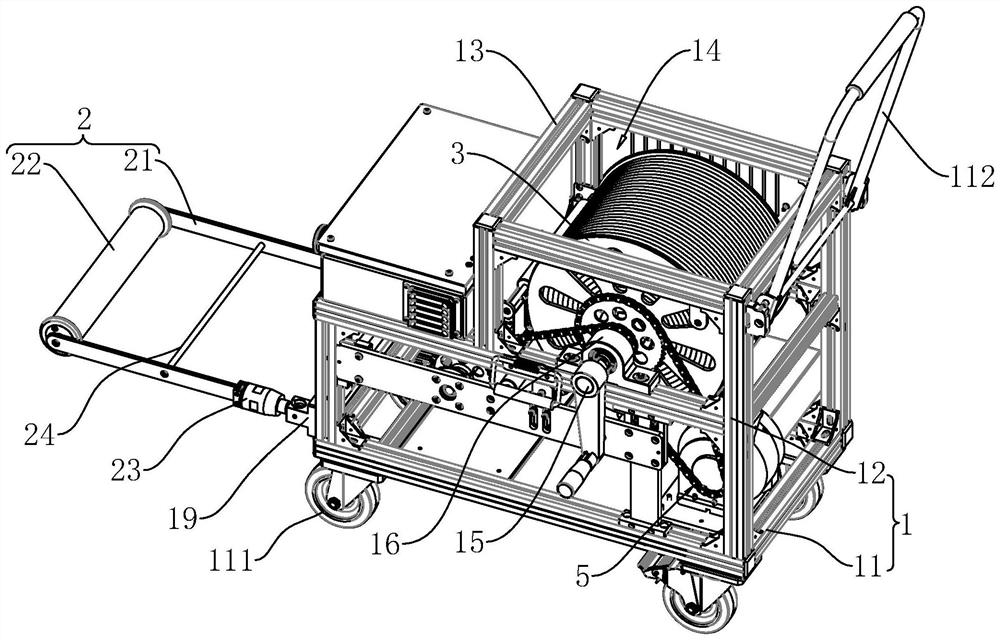

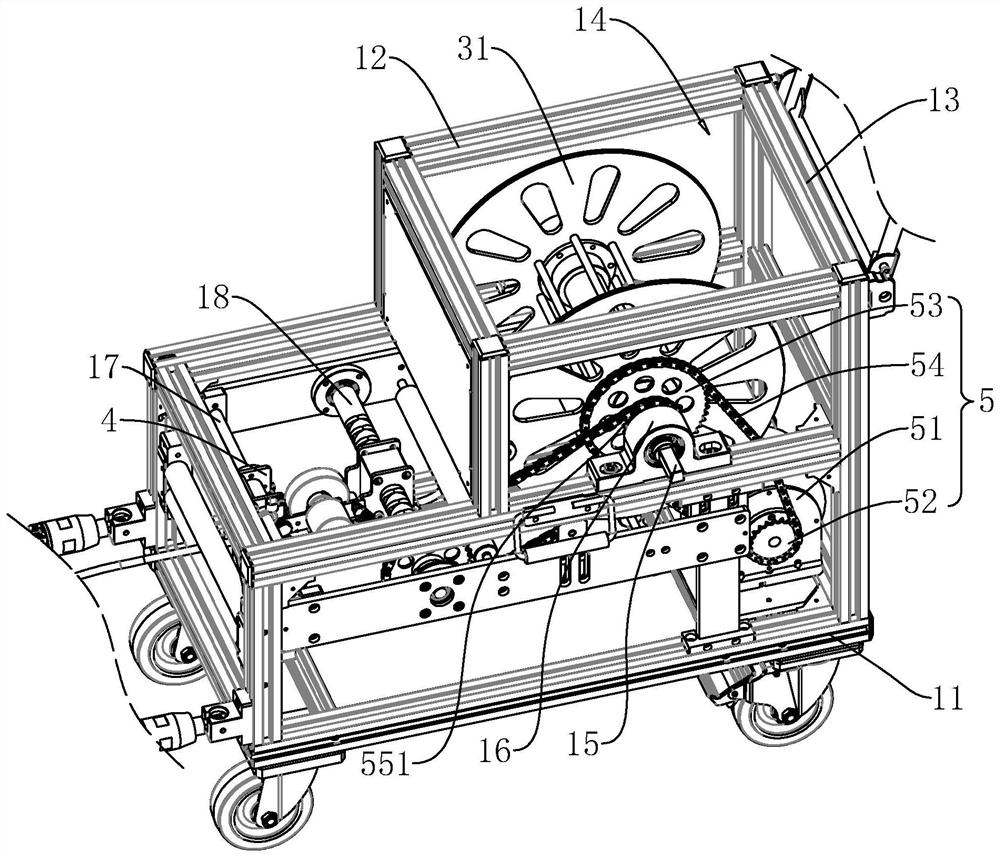

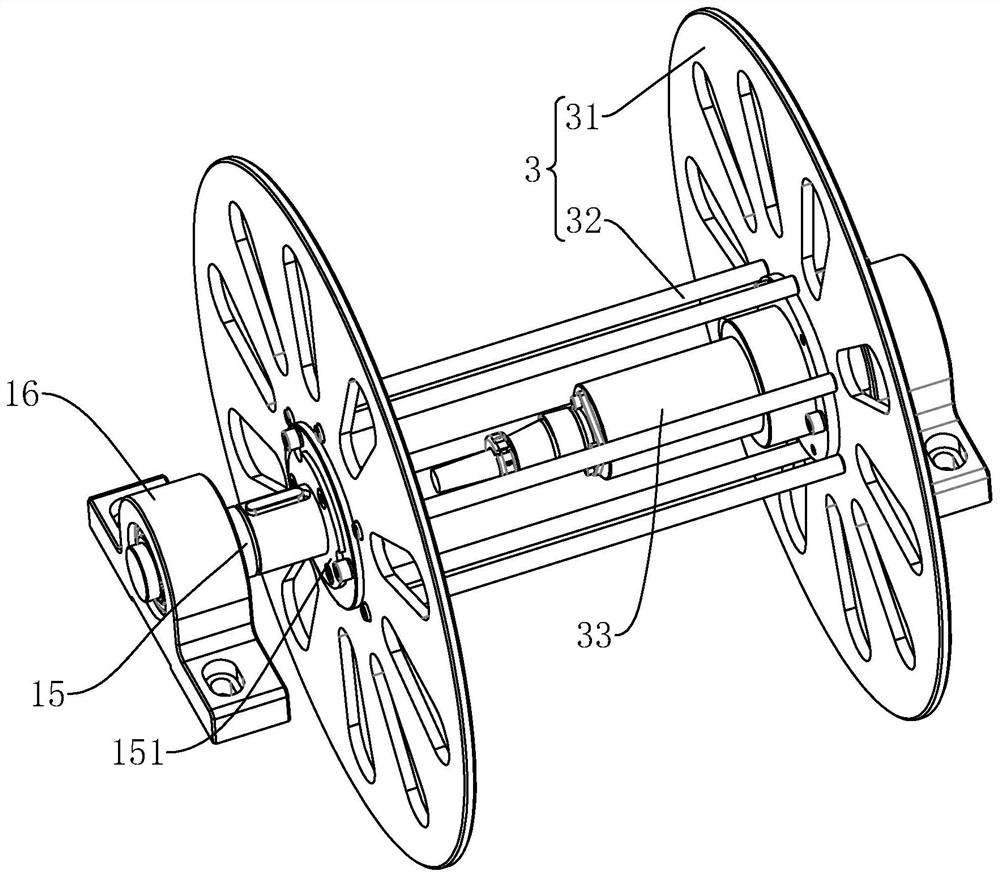

[0050] This embodiment discloses an automatic pay-off car, referring to figure 1 , figure 2 , including a frame body 1, a movable guide frame 2 hinged on one side of the frame body 1, a cable reel 3 rotatably connected to the frame body 1 for winding or unwinding cables, and a sliding connection on the cable seat 4 of the frame body 1.

[0051] The frame body 1 includes a bottom frame 11 , a pair of side frames 12 fixedly connected to both sides of the bottom frame 11 , and several connecting beams 13 fixedly connected between the two side frames 12 . The bottom of the bottom frame 11 is provided with moving wheels 111, and there are four moving wheels 111 which are respectively located at the four corners of the bottom of the bottom frame 11. Specifically, the moving wheels 111 are universal wheels, and one side of the side frame 12 is fixed A push rod 112 is connected to facilitate the staff to push the frame body 1 of the vehicle frame.

[0052] refer to figure 2 , ...

Embodiment 2

[0061] Embodiment 2: refer to Figure 13 , Figure 14 , the difference from Embodiment 1 is that the two guide support plates 21 are fixedly connected with a reinforcing plate 25, and the reinforcing plate 25 includes a mounting plate 251, a movable plate 252 slidingly connected to the mounting plate 251, and a movable plate 252 fixedly connected to the mounting plate 251 and the second elastic member 253 between the movable plate 252. The mounting plate 251 has an inner cavity for accommodating the movable plate 252 , and the mounting plate 251 has an outlet communicating with the inner cavity for the movable plate 252 to extend out. The second elastic member 253 is a spring. One end of the spring is fixedly connected to the inner wall of the inner cavity of the mounting plate 251 and the other end is fixedly connected to the movable plate 252 .

[0062] refer to Figure 14 , Figure 15A mounting sleeve 26 is fixedly connected between the two movable plates 252, and a cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com