Extra-long plate flanging machine

A technology of edge folding machine and sheet metal, applied in metal processing equipment, feeding device, positioning device, etc., can solve the problem of discontinuous creases, achieve force balance and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

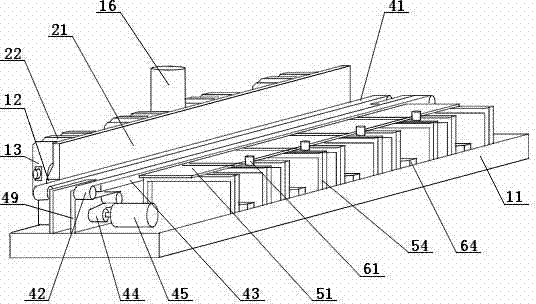

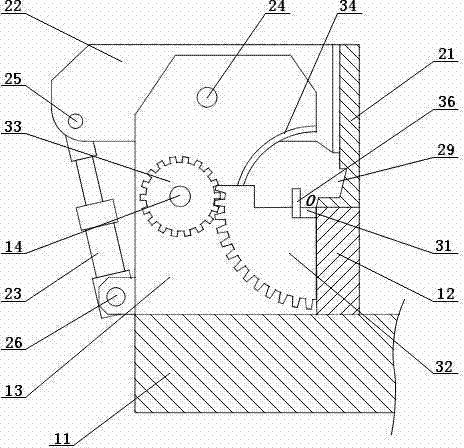

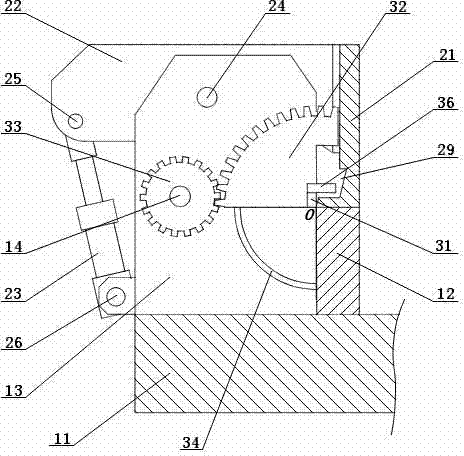

[0029] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a super-long panel folding machine in this embodiment is composed of a folding mechanism, a transmission mechanism, a side pushing mechanism and a base 11 .

[0030] The hemming mechanism in this embodiment includes a platen table 12, a platen mold strip 21, a hemming mold strip 31 and a plurality of power units. The platen table 12 is installed on the base 11 and is in the shape of a strip. Both the pressing plate mold strip 21 and the hemming mold strip 31 are of elongated structure. The pressing plate molding strip 21 is located above the pressing plate table 12 . A plurality of power units are alternately arranged along the longitudinal direction of the pressing plate mold strip 21 and the hemming mold strip 31 . In this embodiment, the distance between two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com