Conveyor

A technology of a transmission device and a conveyor belt is applied in the field of transmission appliances, which can solve the problems of increased use of personnel, low efficiency, and increased cost, and achieves the effects of good diversion effect, large transmission volume, and convenient transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

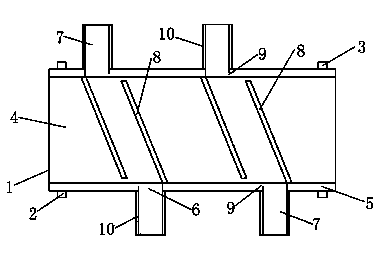

[0014] Combine below figure 1 Specific examples:

[0015] A transmission device, comprising a frame 1, the frame 1 is provided with a driving roller 2 and a driven roller 3, the driving roller 2 is connected with a motor, the driving roller 2 and the slave A conveyor belt 4 is provided on the moving roller 3, and the conveyor belt 4 is movable under the driving of the driving roller 2 and the driven roller 3. The frame 1 is provided with protective plates 5 on both sides of the conveyor belt 4 , The protective plate 5 is provided with a plurality of notches 6, and the notches 6 are connected with a plurality of shunt grooves 7, and the notches 6 are hinged with a shunt plate 8, and the shunt plate 8 can block the notch 6. , The length of the dividing plate 8 is greater than the width of the conveyor belt 4. A gap 9 is opened at the junction of the shunt groove 7 and the protective plate 5, and the other end of the shunt plate 8 can be clamped in the gap 9. Baffles 10 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com