Driven slide carriage for numerical-control cutting machine

A cutting machine and slide plate technology, applied in welding/cutting auxiliary equipment, auxiliary equipment, gas flame welding equipment, etc., can solve the problems of poor stability, unreasonable design, unsuitable for production, etc., and achieve reasonable structural design and installation Ease of maintenance and ensuring cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

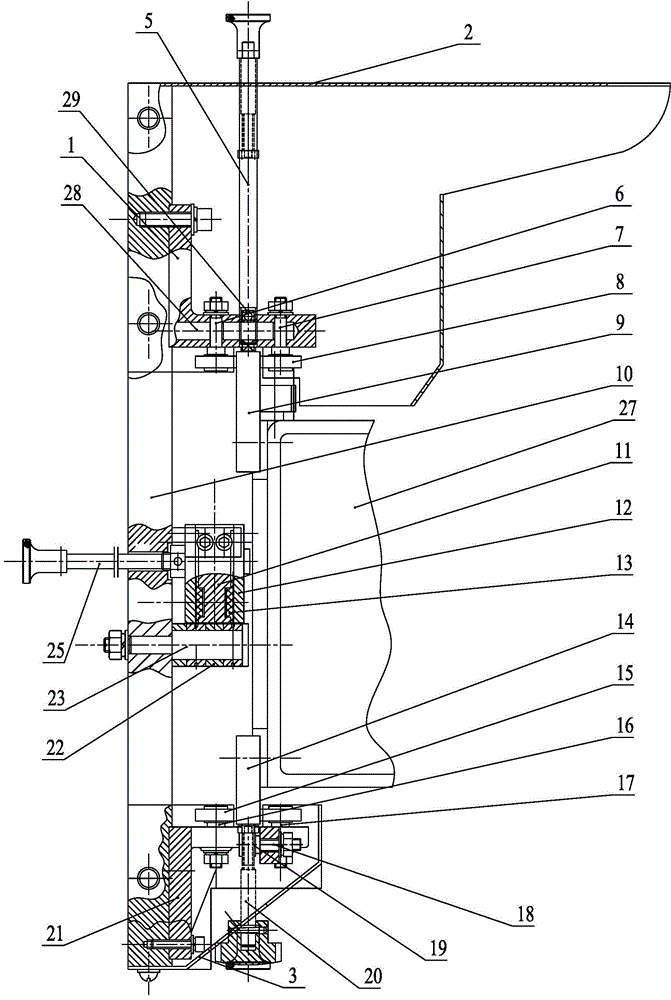

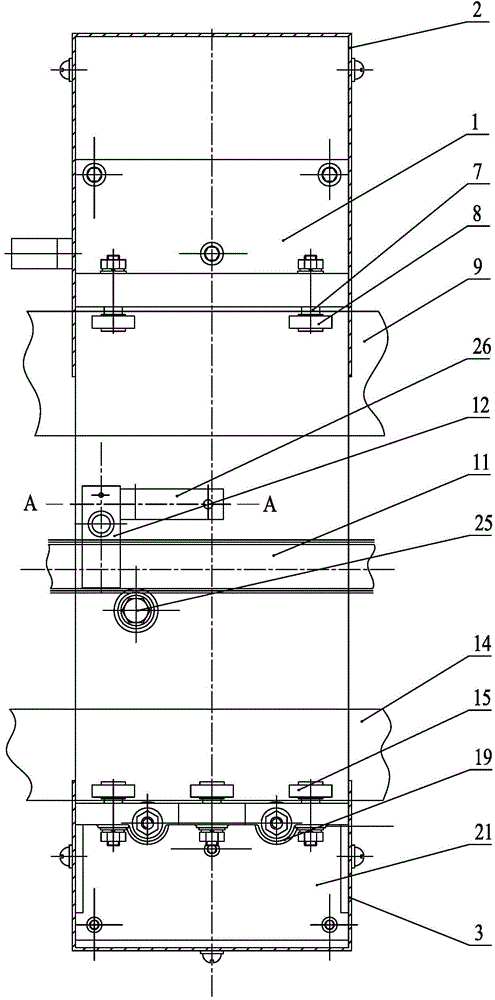

[0016] As shown in the figure, the driven slide plate in the embodiment is installed on the crossbeam 27 of the CNC cutting machine, and the upper and lower sides of the crossbeam 27 are respectively provided with an upper slide plate 9 and a lower slide plate 14; the driven slide plate is mainly composed of The front plate 10 and the lower support mechanism installed on the front plate 10, the upper support mechanism, the sliding plate locking mechanism and the auxiliary locking mechanism etc. are composed.

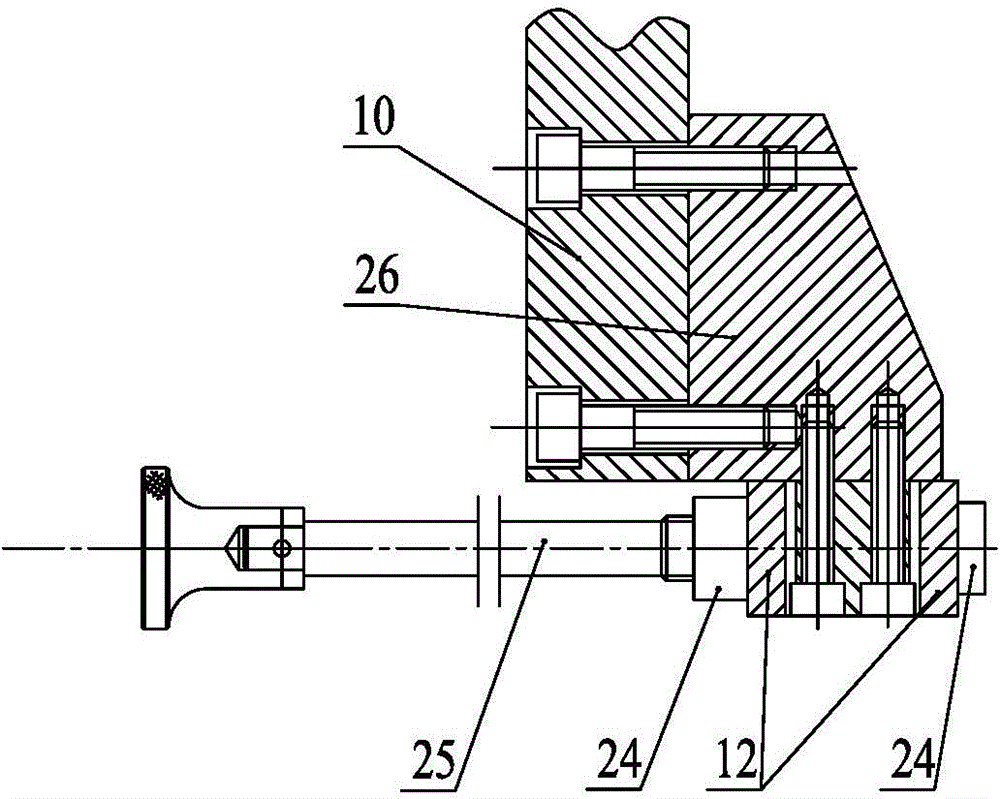

[0017] The structure of the upper supporting mechanism is as follows: figure 1 , figure 2 As shown, it is mainly composed of an upper bracket 1, an upper support shaft 28, an upper support bearing 29, an upper fixed shaft 7, an upper eccentric shaft 6 and an upper bearing 8. The upper bracket 1 is fixedly installed on the side wall of the front plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com