High-strength light H-shaped steel and hot rolling forming process thereof

A technology of hot-rolled forming and H-shaped steel, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of reduced rolling production speed, product quality decline, long rolling time, etc., to speed up rolling production Speed, guaranteed product quality, and shortened rolling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of high-strength light-weight H-shaped steel and its hot rolling forming process

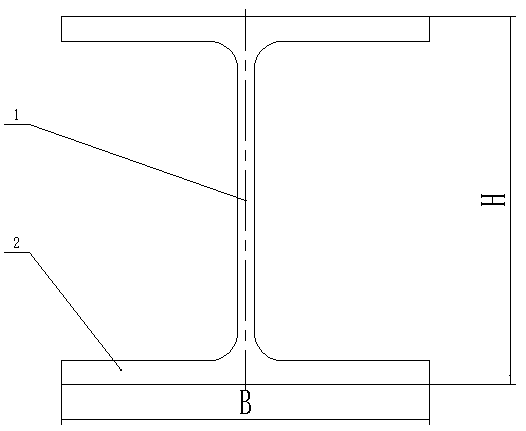

[0027] like figure 1 As shown, the present invention provides a high-strength light-weight H-shaped steel, comprising a web 1 and flanges 2 arranged on both sides of the web, including a web and flanges arranged on both sides of the web;

[0028] The height H of the H-shaped steel is 143-149 mm, the width B is 91-99 mm, the web thickness is 2.9-3.7 mm, and the wing plate thickness is 3.3-4.7 mm.

[0029] The height H of the H-shaped steel is 143-149mm, preferably 146mm;

[0030] Width B is 91-99mm, preferably 95mm;

[0031] The web thickness is 2.9-3.7mm, preferably 3.3mm;

[0032] The thickness of the wing plate is 3.3-4.7 mm; preferably 4.0 mm.

[0033] A high-strength light H-shaped steel hot rolling forming process, comprising the following steps:

[0034] S1 blank selection

[0035] The material of the billet is carbon structural steel or low alloy steel; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com