Patents

Literature

58results about How to "Save rolling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low welding crack sensitivity, quenching and tempering, high rigid plate and manufacturing method thereof

ActiveCN101476080AGuaranteed continuityReduce time on rollTemperature control deviceFurnace typesForeign matterHigh intensity

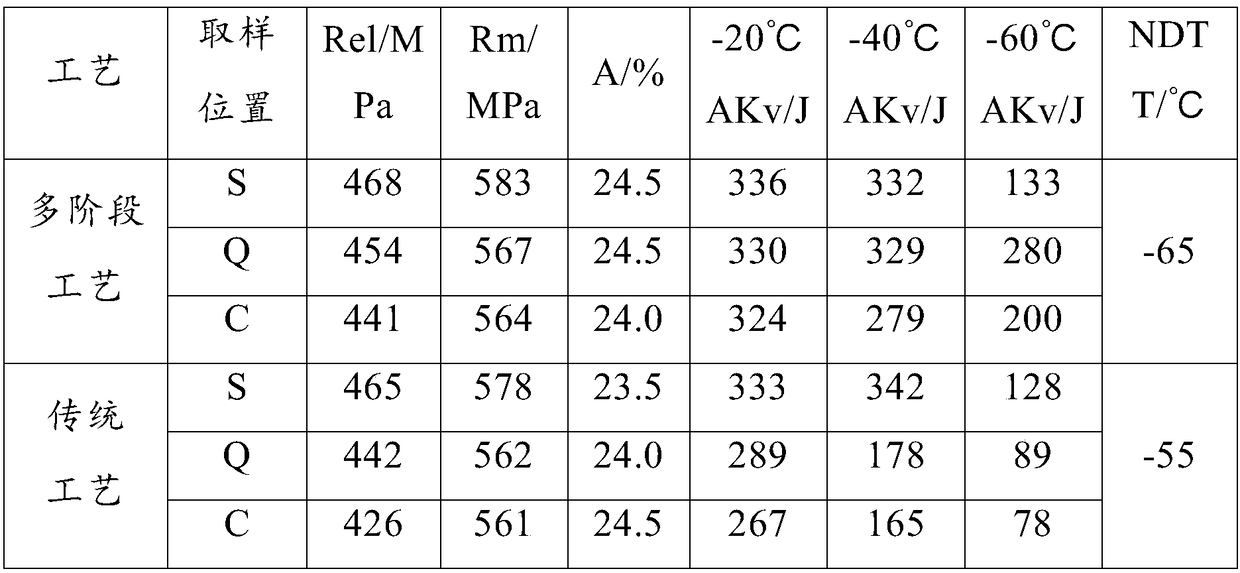

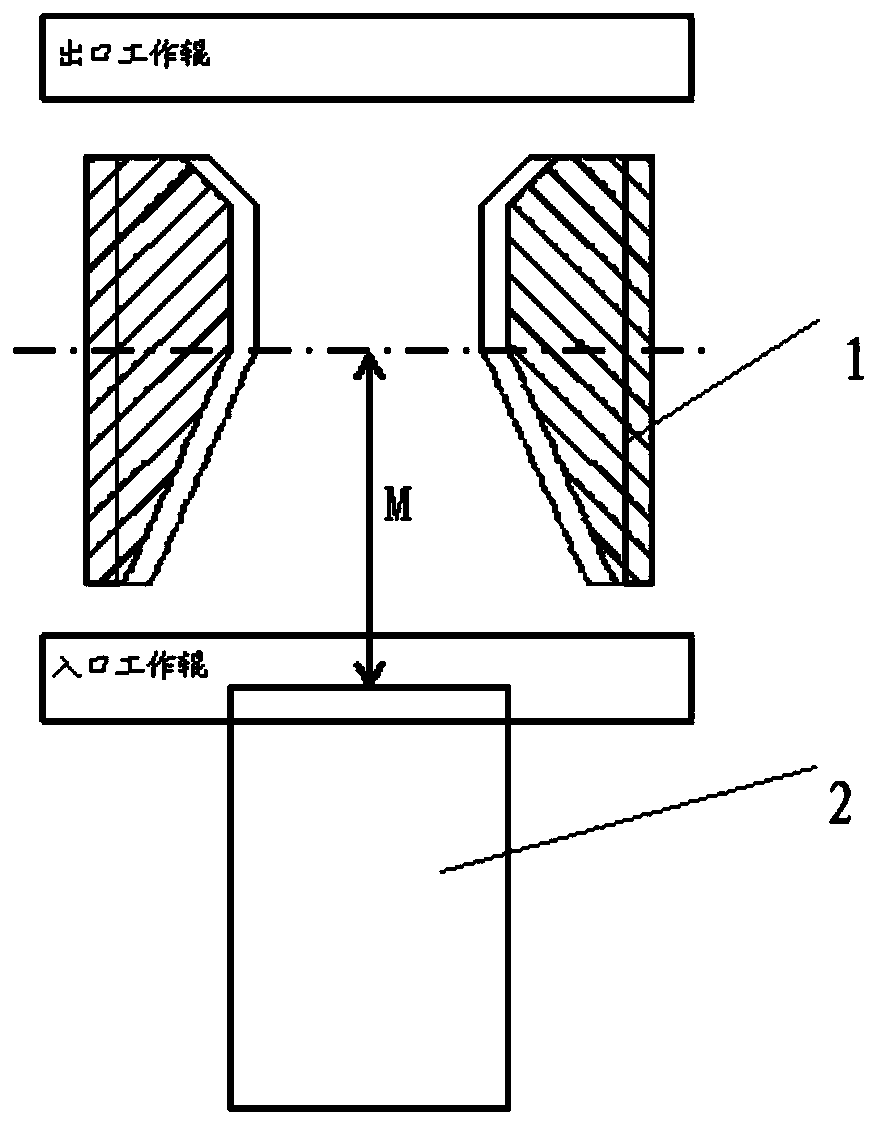

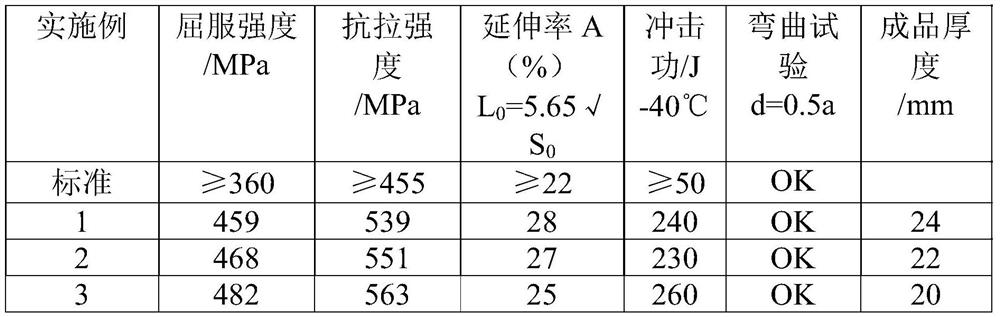

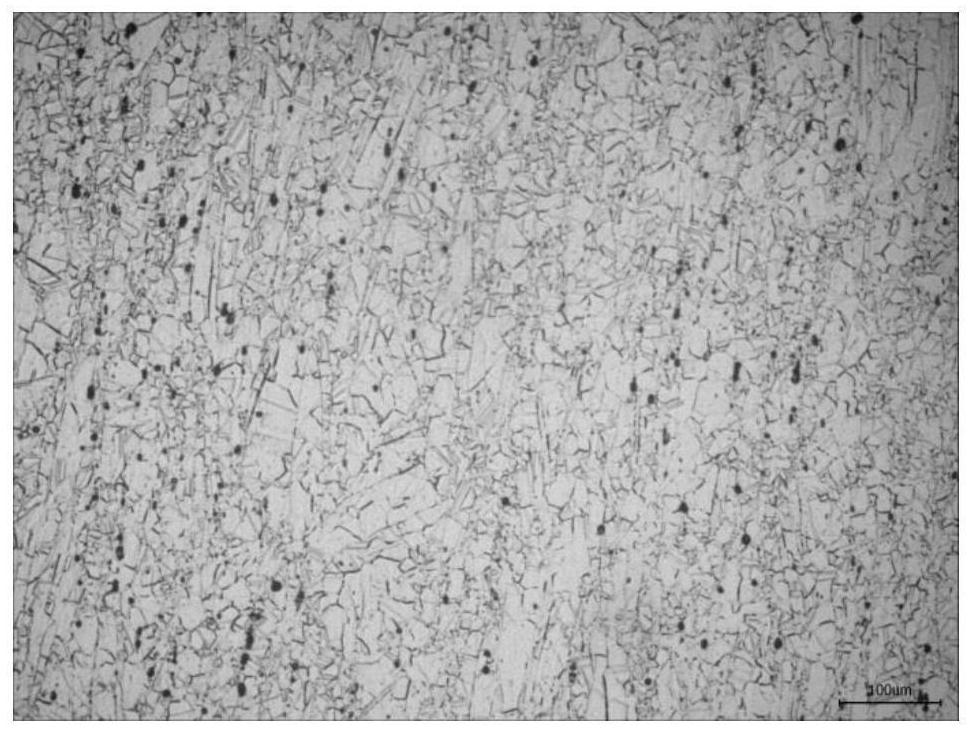

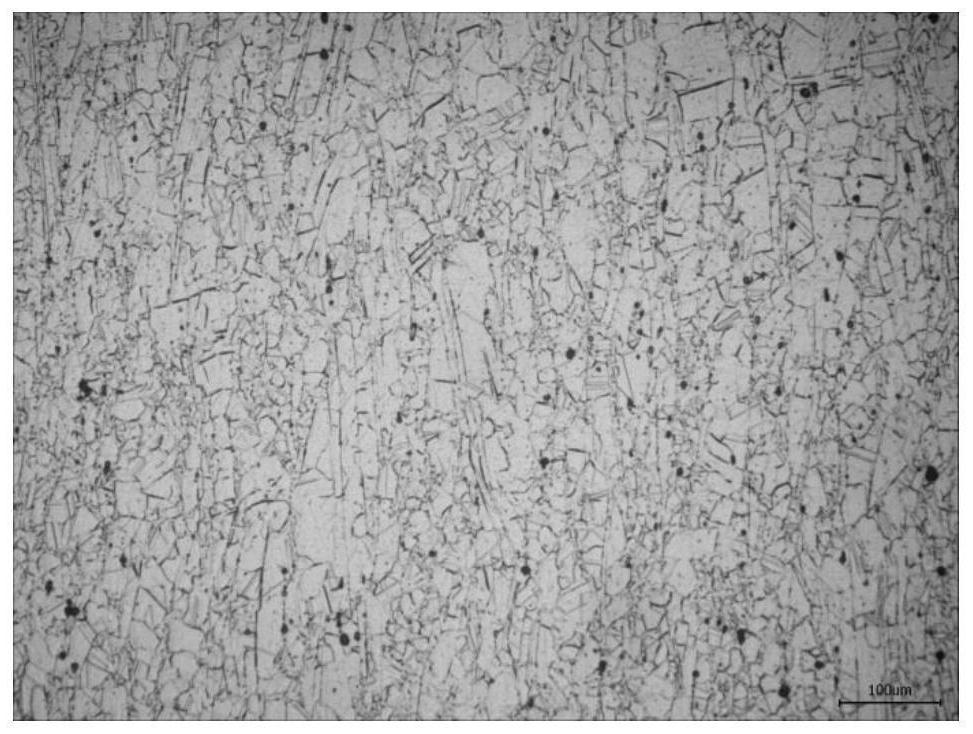

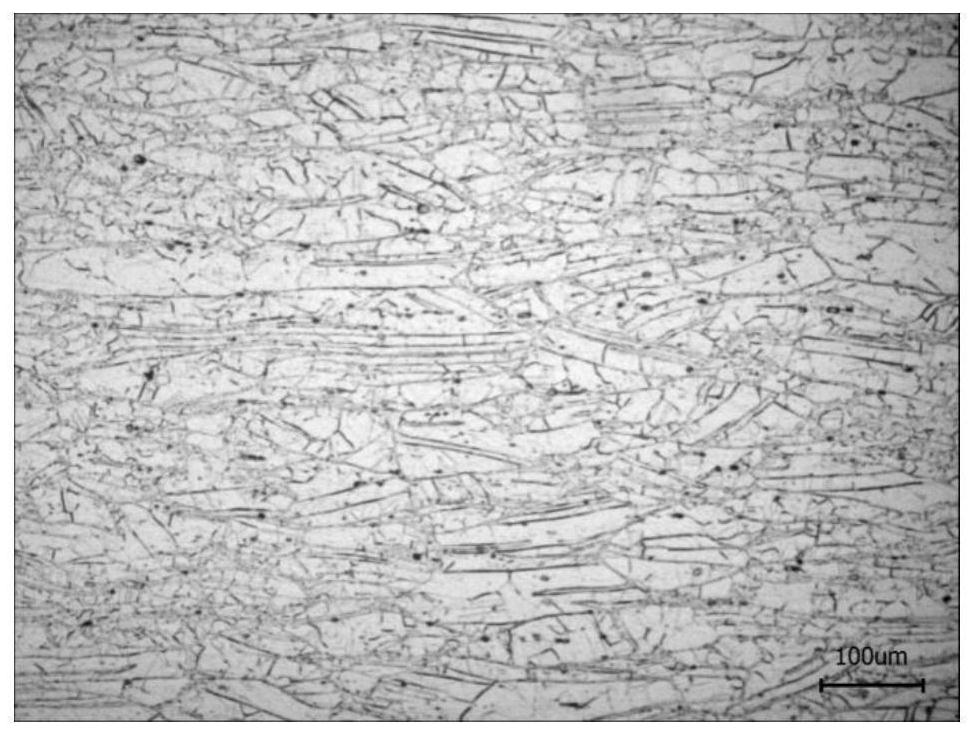

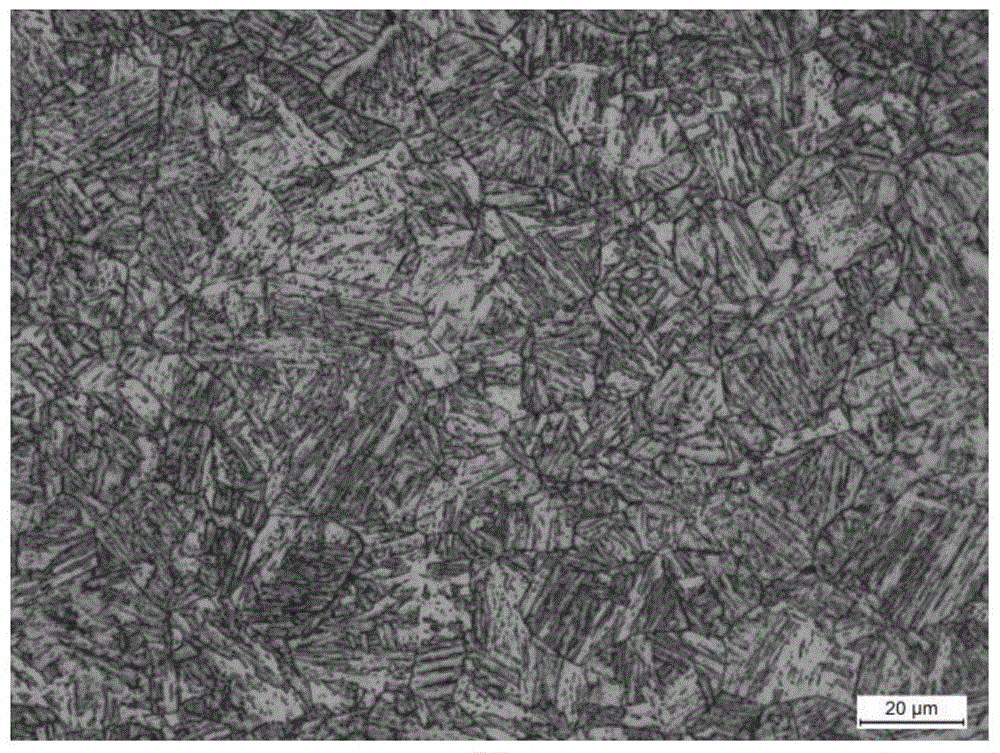

The invention pertaining to the field of low-alloy steel fabrication technique provides low welding crack sensibility quenching and tempering high-strength steel plates and a method for producing the same. The steel plate comprises the following chemical components by quality percent: C of 0.07-0.09%, Si of 0.20-0.40%, Mn of 1.20-1.40%, Alt of 0.30-0.50%, Mo of 0.10-0.20%, V of 0.04-0.06%, Ti of 0.01-0.02%, and Fe and ineluctable foreign matters of the rest; the tissue are secondary troostite and tempering sorbite.Comparing with the two-stage or three-stage rolling, the rolling adopting a austenite perfect recrystallization section has advantages of omitting a temperature-holding stage for assuring the consistency of rolling steel plates and greatly shortening the rolling time of steel blocks on the basis of simplified processes; rolling only in high-temperature regions, therefore, reducing the requirement of the ability of rolling mill equipment and simultaneously shortening the on-rolling time of the steel plates in a high temperature; room-temperature tissue obtained after rolling providing an appropriate tissue base for obtaining homogeneous tissue after quenching and tempering the steel plates.

Owner:SHOUGANG CORPORATION

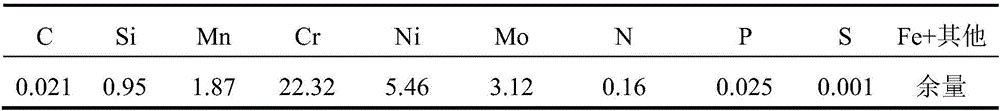

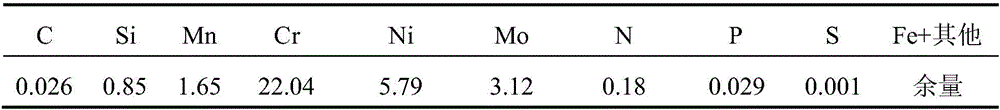

Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

InactiveCN106391704AQuality improvementNo crackWork treatment devicesMetal rolling arrangementsReduction rateMetallurgy

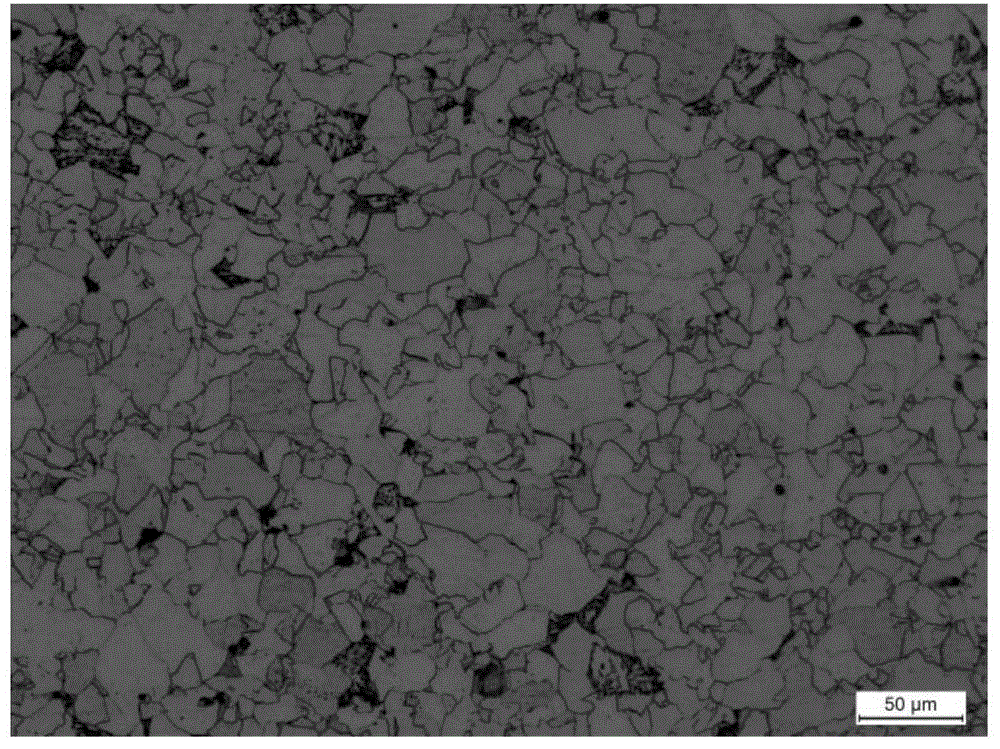

The invention belongs to the technical field of stainless steel rolling, and particularly discloses a method for eliminating cracks of a hot processed surface of a 2205 dual-phase stainless steel middle plate. The method is characterized by comprising the steps that blank selection and grinding are carried out; a cast blank is heated, specifically, the temperature of a preheating section is 1100-1150 DEG C, the temperature of a heating section is 1150-1240 DEG C, the temperature of a soaking section is 1220-1240 DEG C, and for every 10 mm of the cast blank thickness, the furnace standing time is 9-10 min; scale removal is carried out with water of high pressure of 20-25 MPa; the initial rough rolling temperature is higher than 1150 DEG C, the reduction rate is smaller than 25%, rolling is carried out for 8-11 passes, and the thickness of an intermediate blank is 35-45 mm; and the initial finish rolling temperature is larger than 1050 DEG C, the final rolling temperature is larger than 950 DEG C, the reduction rate is smaller than 18%, and rolling is carried out for 8-12 passes. The method has the advantages that the blank specifications are selected reasonably, parameters such as rolling temperature and reduction rate are matched reasonably after grinding and optimal heating, and the surface crack defect of the 2205 dual-phase stainless steel middle plate is effectively avoided.

Owner:NORTHEASTERN UNIV

Method for preventing scale pits of steel plate

ActiveCN102343373AReduce oxidizing atmosphereReduce the temperature difference between the upper and lower surfacesWork treatment devicesMetal rolling arrangementsSheet steelNitrogen

The invention relates to a method for preventing scale pits of a steel plate, which includes the following steps:(1) installing a wiper plate: adding a wiper plate on the working roll of a roller; (2) removing scales through high-pressure water and blowing air: adding an air blower on the tag board of the roller, wherein an air source is nitrogen; and removing the scales on the surface of the steel plate through the high-pressure water and blowing the nitrogen to the descaled steel plate. When rolling the steel plate, water is sprayed to cool the working roll of the roller and the wiper plateprevents the cooling water of the rolling system of the roller from directly spraying the surface of the steel plate, thus retarding oxidation rate of the steel plate. Meanwhile, the scales on the surface of the steel plate are removed through the high-pressure water and the nitrogen is blown to the descaled steel plate. In the process of throwing the rolled piece out of the roller and relieving the stress, under the diluting action of the nitrogen blown out, oxydic air surrounding the steel plate can be reduced and thereby a protective gas layer can be formed around the steel plate, thus preventing oxidation once again and reducing amount of secondary scales.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

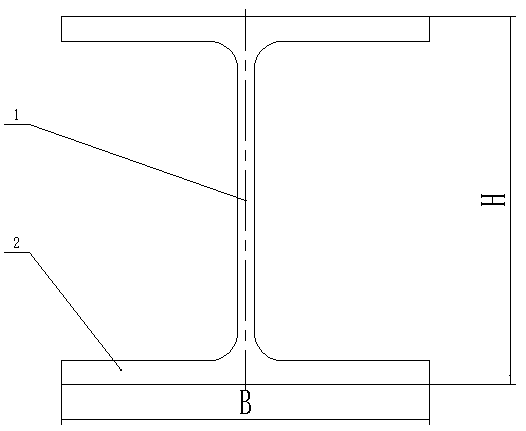

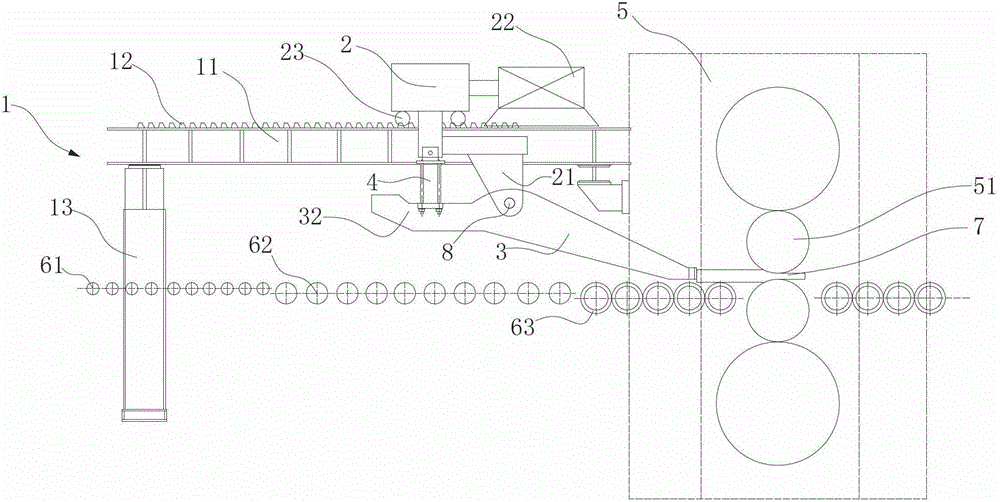

Optimal controlled rolling method adopting ultra-fast cooling to control Austenite structure

At present, an ultra-fast cooling technology is mainly applied to cooling of steel after two-stage controlled rolling. The invention discloses an optimal controlled rolling method adopting ultra-fast cooling to control an Austenite structure and belongs to the technical field of metallurgy. According to the method, the steel can be completely rolled in a steel billet Austenite recrystallization zone, rolling temperature and pass reduction rate can be simultaneously precisely controlled, an ultra-fast cooling system is immediately adopted to cool the rolled steel to a phase transition point after rolling, and then different cooling paths are adopted according to needs to control the phase transition of the steel. According to the method disclosed by the invention, the ultra-fast cooling is adopted, so that coarsening of the small re-crystallized Austenite structure can be effectively inhibited, and the refining effects of dynamic recrystallization and sub-dynamic recrystallization against the Austenite structure in a high-temperature rolling process can be retained. The product manufactured by the method disclosed by the invention and the steel manufactured by the two-stage controlled rolling process have equivalent mechanical properties, so that the rolling time is simultaneously reduced by 2-4min in comparison with the two-stage controlled rolling process at a waiting temperature and low-temperature atmosphere in the rolling process.

Owner:NORTHEASTERN UNIV

Rolling method of high-grade non-oriented silicon steel

ActiveCN108655173AIncrease heat of deformationReduced edge cracking tendencyRoll force/gap control deviceTension/compression control deviceTemperature controlReduction ratio

The invention relates to a rolling method of high-grade non-oriented silicon steel. Through four-time rolling, reduction ratios are increased so as to increase deformation heat of strip steel, so thata rolling temperature of the strip steel is increased, and a temperature of an incoming material is controlled to reach 55 DEG C to 60 DEG C; the scheme of the four-time reduction ratios comprises that the reduction ratio for the first time is 37 percent to 41 percent, the reduction ratio for the second time is 36 percent to 39 percent, and the reduction ratio for the third time is 34 percent to37 percent; rolling force for the four times is respectively controlled as follows: 4750kN to 5000kN, 4600kN to 5000kN, 4400kN to 4600kN and 3900kN to 4200kN; and unit tension adjustment on rolling atthe previous two times is carried out. The rolling method of the high-grade non-oriented silicon steel disclosed by the invention has the advantages that the rolling times are simplified, the trend of edge cracking of an edge part of the strip steel is reduced, and production of double -rib wave is reduced.

Owner:ANGANG STEEL CO LTD

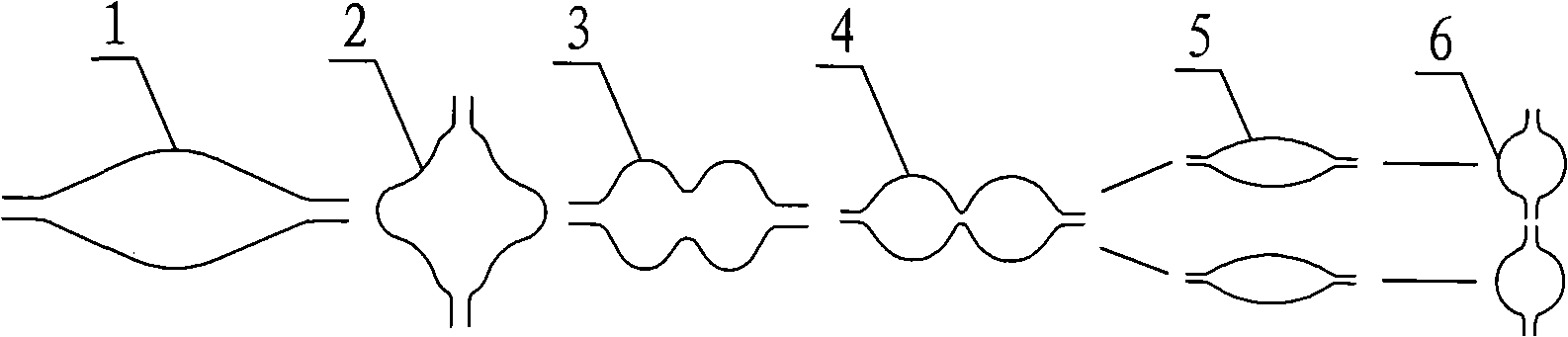

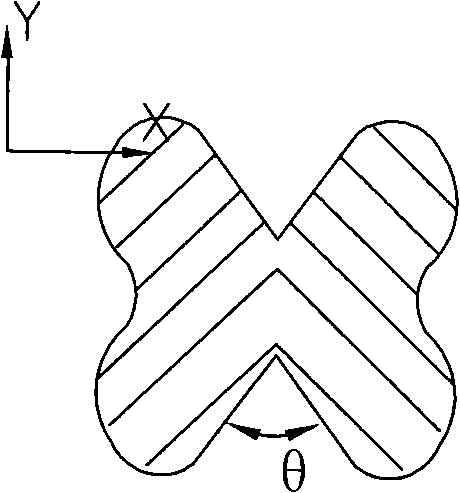

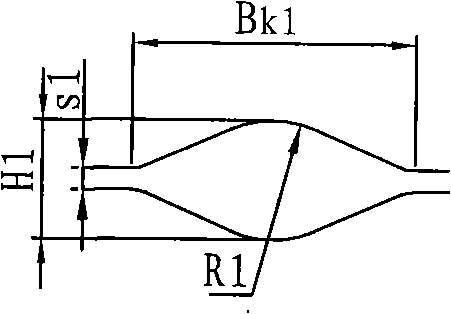

Round steel splitting rolling technique

InactiveCN101306432AHigh speedImprove machine-hour throughputRollsMetal rolling arrangementsProduction rateEllipse

The invention discloses a slit rolling technique of round steel, which comprises the following steps: a blank is rolled into parallel rolled pieces after undergoing the stages of rough rolling, medium rolling and precision rolling; the rolled pieces are slit by a slitting wheel for obtaining the round steel rolled pieces, wherein the roll passes with specific structures and sizes including the rhomboid pass, the cinquefoil square pass, the dumbbell-shaped pre-slit pass, the double-circle slitting pass, the ellipse pass and the round pass are sequentially adopted in the medium rolling and the precision rolling stages, the square rolled pieces rolled by the cinquefoil square pass require further slitting and positioning by a slitting wedge, and the point angle Theta of the slitting wedge is 60 DEG- 65 DEG; finally each thin and narrow connecting band of the rolled pieces is slit by the slitting wheel on a slitting foreplate, wherein the point angle of the slitting wheel is 90 DEG- 95 DEG. The round steel produced by adopting the slit rolling technique of the invention has good surface quality and high production rate, and the slit rolling process can effectively improve the machine-hour yield of the round steel and increase the production efficiency in a factory.

Owner:XINJIANG BAYI IRON & STEEL

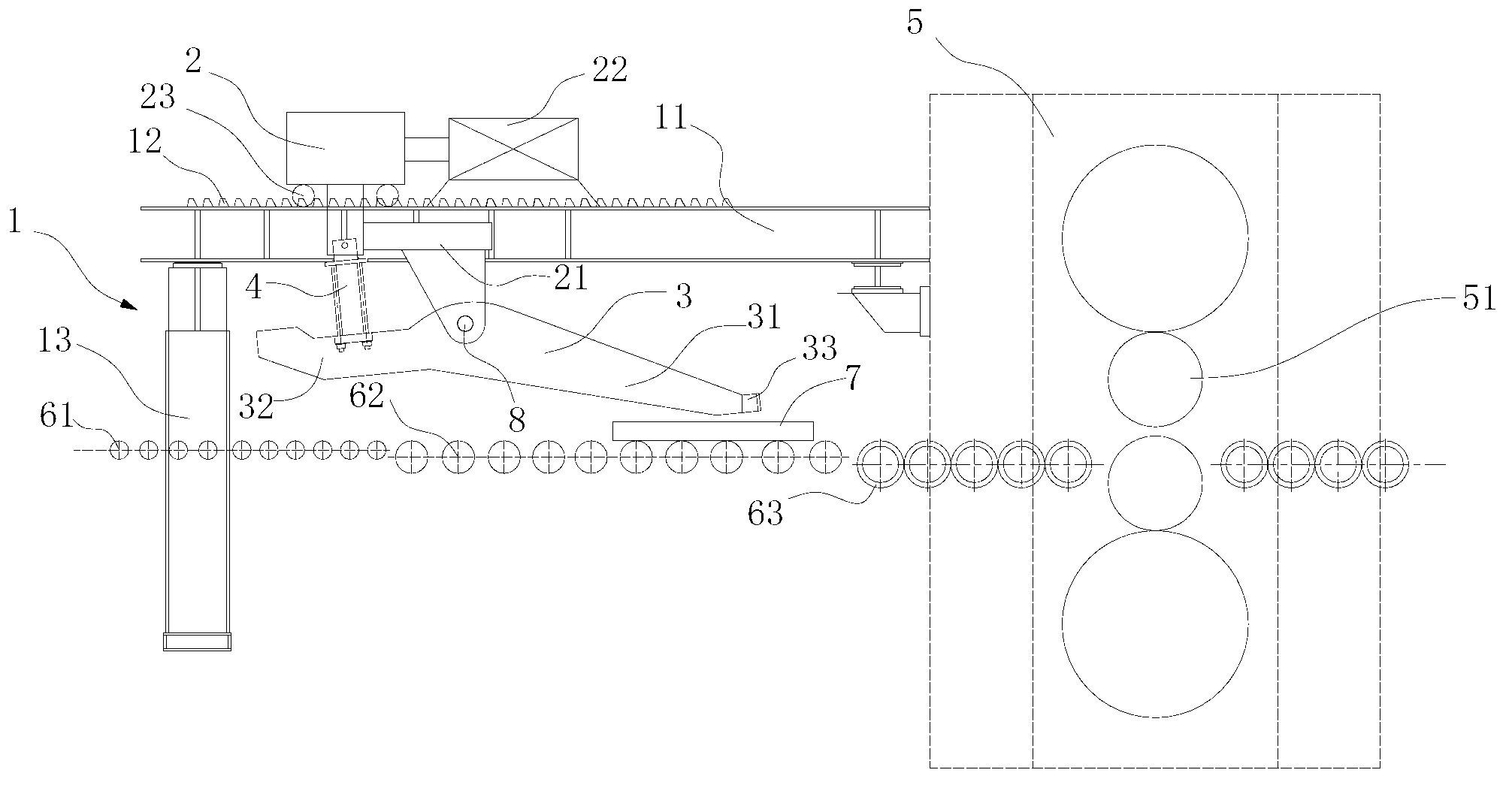

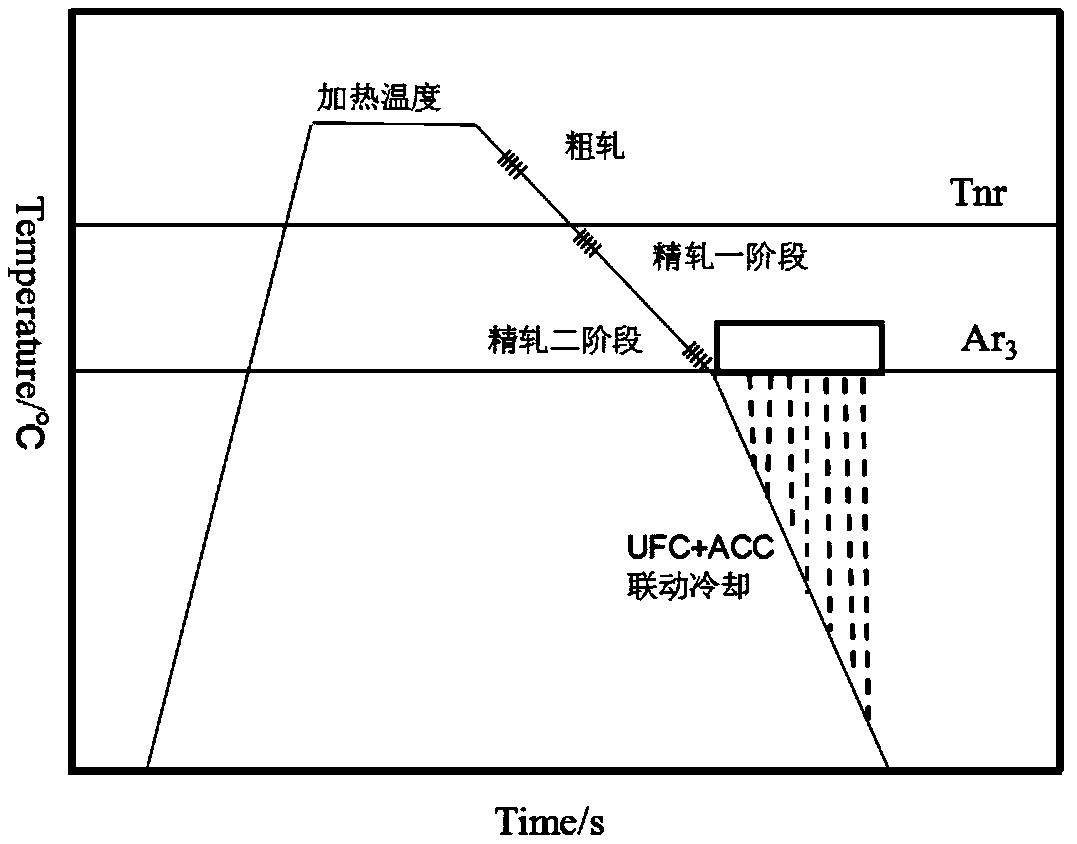

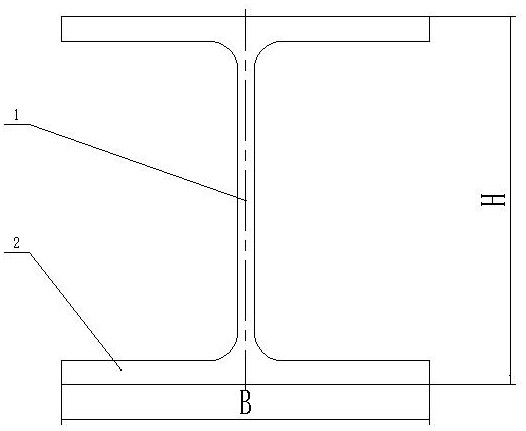

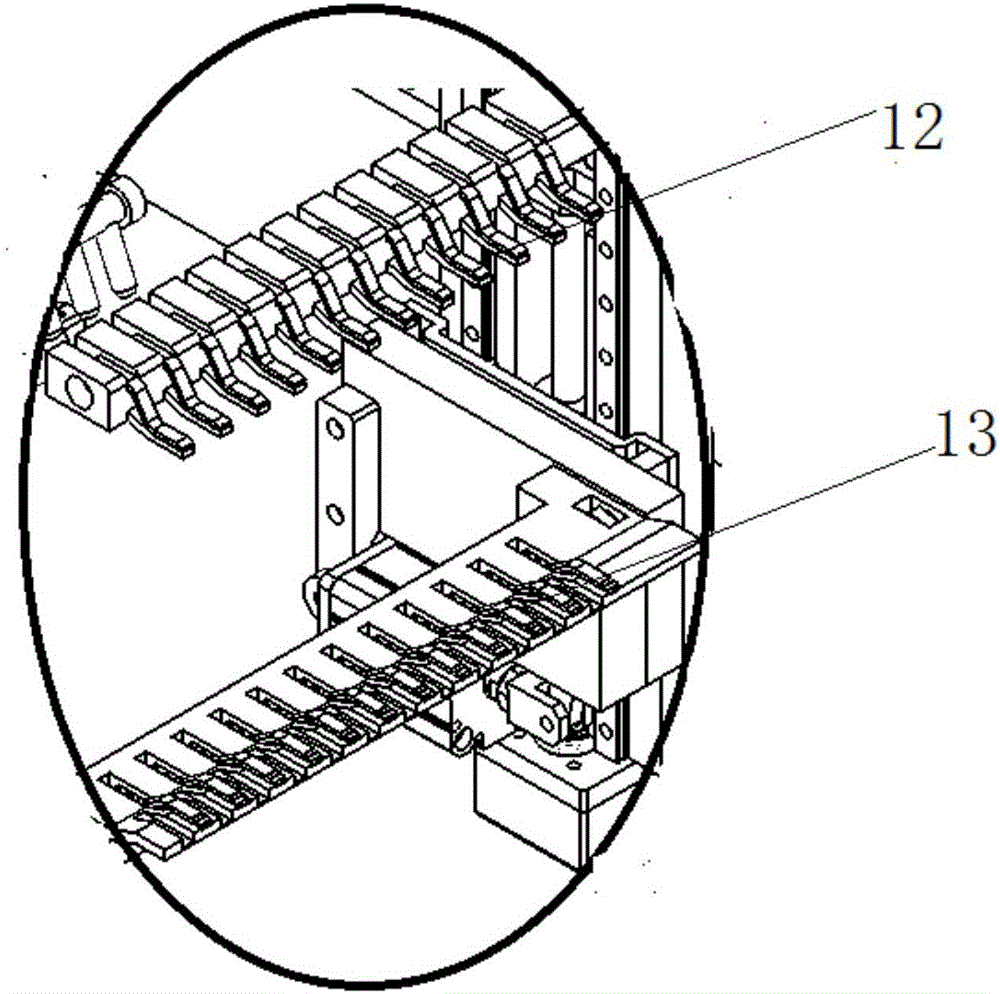

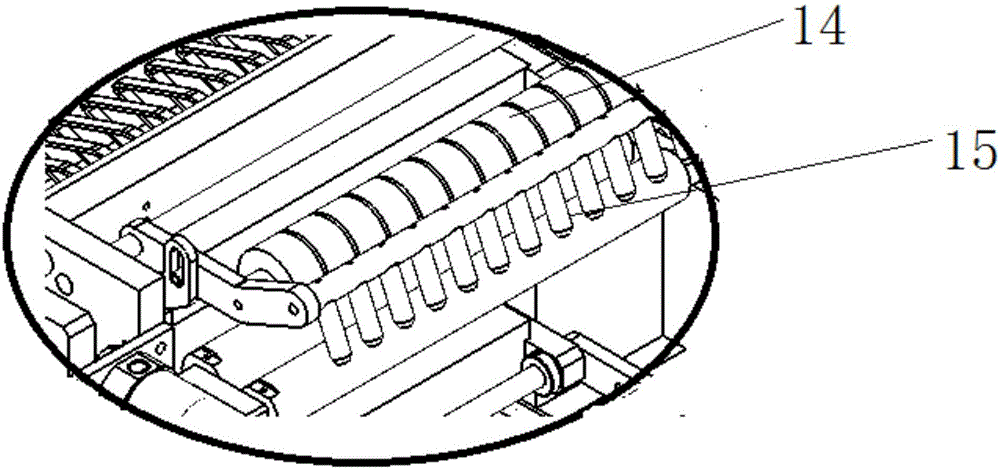

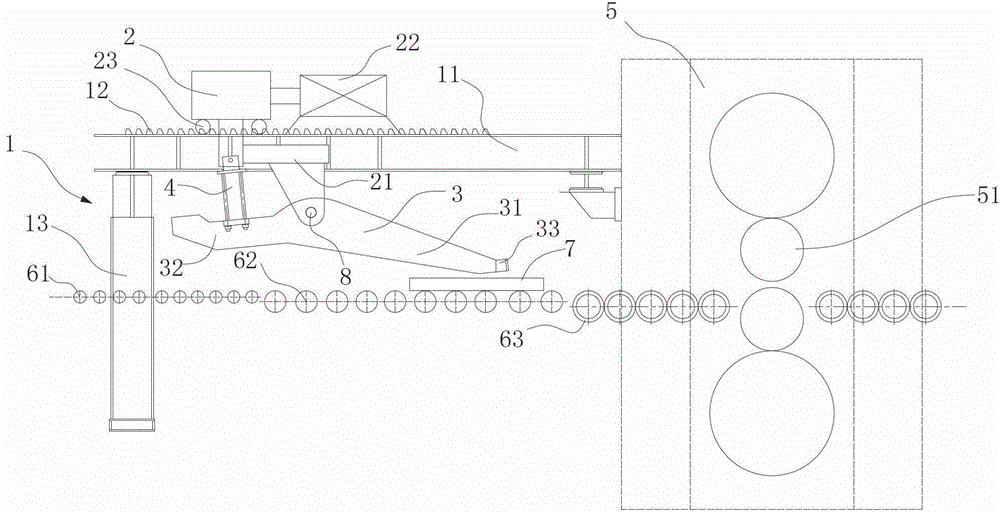

Forced rolling mill feed device

ActiveCN103252362AOperational securityEasy to operateMetal rolling arrangementsWorking environmentUltimate tensile strength

The invention discloses and provides a forced rolling mill feed device. According to the forced rolling mill feed device, labor intensity of workers can be reduced, and mechanical feeding can be achieved. The forced feed device comprises a supporting machine base, a translation trolley and a lifting frame. A suspension frame is arranged on the supporting machine base, the translation trolley is arranged on the suspension frame of the supporting machine base, the lifting frame is connected on the translation trolley through a lifting device, and the lifting frame is located below the suspension frame of the supporting machine base. The forced rolling mill feed device is adopted to feed rolling pieces, the labor intensity can be effectively reduced, energy consumption is reduced, production efficiency is improved, and the production rhythm is accelerated. The forced rolling mill feed device can also be applied to the field of rolling and producing rare and refractory metal pieces, volatilization of the rare and refractory metal pieces can be effectively reduced, pollution to the environment is reduced, and working environment of the workers is improved.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

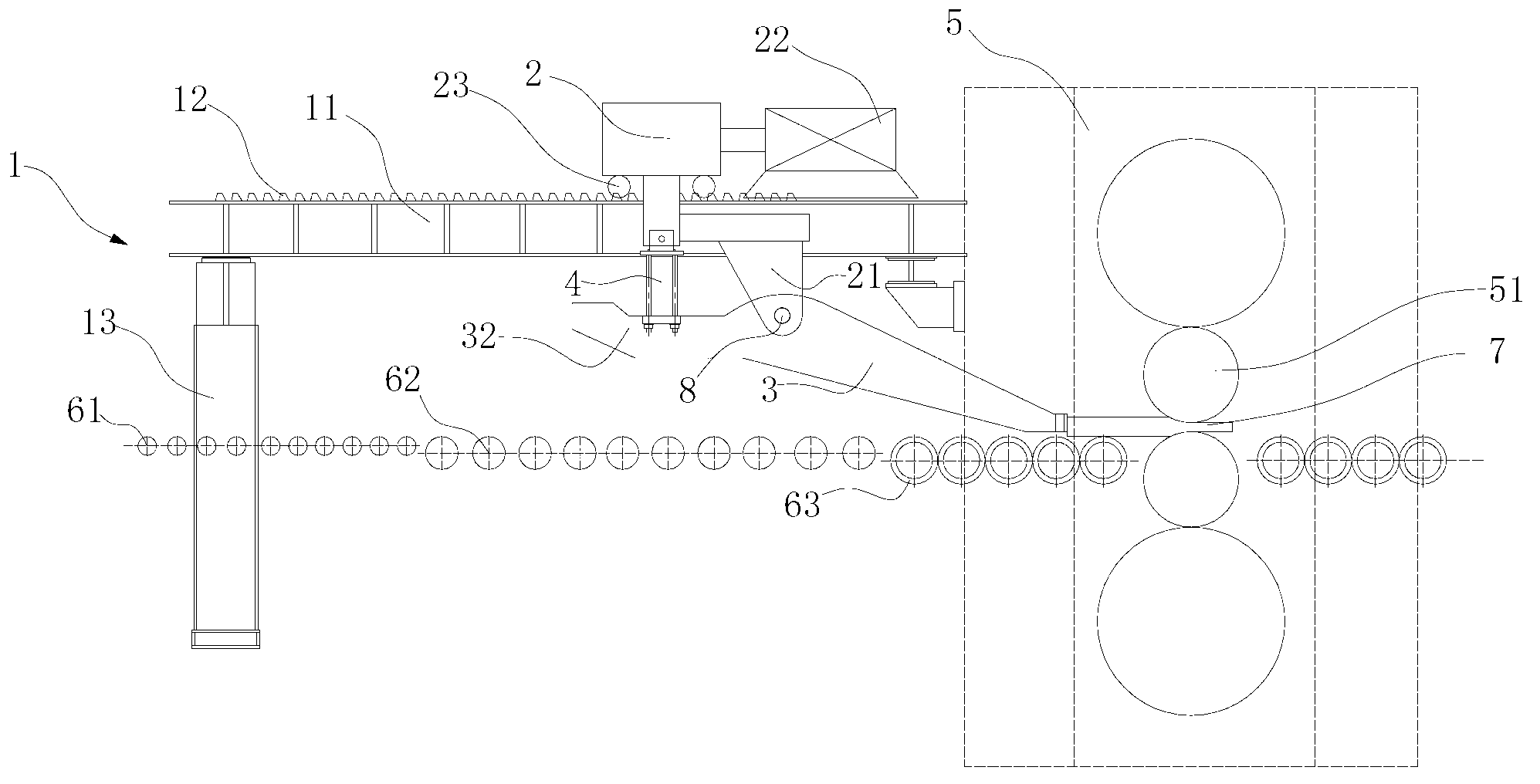

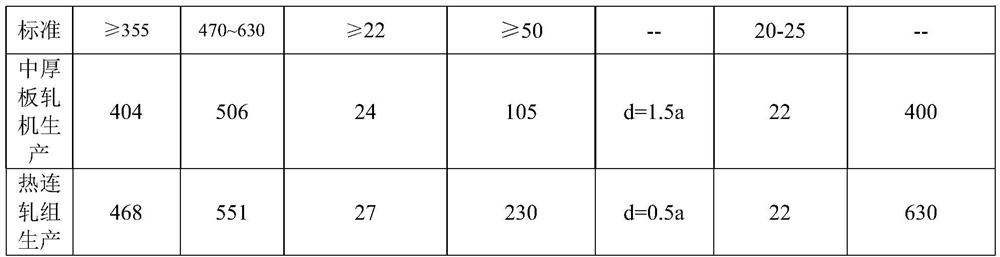

High-strength light H-shaped steel and hot rolling forming process thereof

ActiveCN111468534AHigh strengthReduce weightElongated constructional elementsWork heating devicesEngineeringHigh pressure water

The invention discloses high-strength light H-shaped steel. The high-strength light H-shaped steel comprises a web plate and a wing plate, wherein the height of the web plate is 146 mm, the thicknessof the web plate is 3.3 mm, the width of the wing plate is 95 mm, and the thickness of the wing plate is 4.0 mm. A hot rolling forming process of the H-shaped steel comprises the following steps: carrying out high-pressure water descaling on a heated square steel billet, carrying out head cutting treatment after cogging rough rolling is carried out by two three-roll horizontal rolling mills, carrying out reciprocating rolling 4-6 times through a universal rough rolling unit, finally carrying out reciprocating rolling 1-2 times by a universal finishing rolling unit, and carrying out fixed-length cutting on a rolled piece after the rolled piece is subjected to air cooling by a cooling machine to obtain a finished product. According to the high-strength light H-shaped steel, under the condition that the rolled H-shaped steel has the same height H and width B as standard H-shaped steel, the thickness of the web plate and the thickness of the wing plate are smaller, and the strength of therolled H-shaped steel can be ensured; and in the rolling process, the pass number of cogging rough rolling is obviously reduced, the rolling time is shortened, the temperature drop of the rolled pieceis small, the product quality is guaranteed, the rolling production speed is accelerated, and the production efficiency is improved.

Owner:山东德坊新材料科技有限公司

Rolling method of wide-width thin-specification 6Mo super austenitic stainless steel plate

ActiveCN110756580AIncrease widthReduce the number of weldsTemperature control deviceMetal rolling stand detailsHeating timeSS - Stainless steel

The invention discloses a rolling method of a wide-width thin-specification 6Mo super austenitic stainless steel plate. The rolling method includes the following steps that a blank which has the thickness of 110-125 mm, the width of 1500 mm or above and the length of 2550-2620 mm is adopted; the steel blank is sent to a stepping type heating furnace, the ratio of the total heating time to the thickness of the steel blank is controlled to be 15-22 min / cm, the temperature of a uniform heating section is 1230-1270 DEG C, the time for the uniform heating section is at least 30 min, and the tappingtemperature is 1240-1260 DEG C; full transverse rolling is performed through 12+1 rounds, the reduction rate is increased from 17% in the first round to 30-40% in the fifth round and is then gradually reduced, the reduction rate in the eleventh round is 7-9%, the reduction rate of the twelfth round is 4-6%, and air cooling is performed after rolling; and the solid solution temperature is 1160 DEGC, heat preservation is performed for 20 min, and water cooling is performed. The width of this type of finished products can be increased from 2000 nm in the prior art to 2500 mm.

Owner:NANJING IRON & STEEL CO LTD

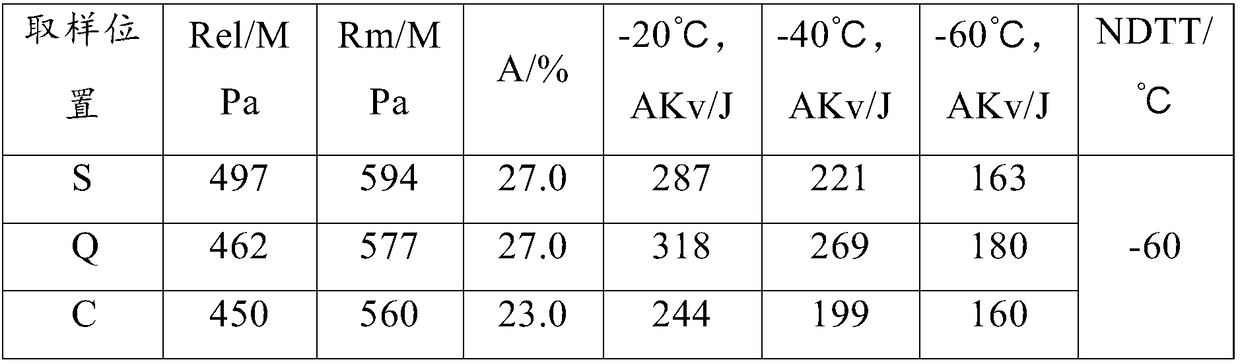

Production method of high-quality thick steel plate

ActiveCN109295290AImprove cross-section low temperature impact toughnessPromote precipitationSheet steelLow speed

The invention belongs to the technical field of steel materials, and discloses a production method of a high-quality thick steel plate. The production method comprises the steps that the procedure ofhigh-temperature rolling and the procedure of low-temperature rolling are conducted in a non-recrystallization area in the rolling process, wherein the procedure of high-temperature rolling comprise afirst finish rolling stage, and in the first finish rolling state, a low-speed high-pressure rolling process is adopted, the initial rolling temperature is 900-930 DEG C, a required cumulative rolling rate is equal to or greater than 15%, and the maximum single-pass rolling rate is equal to or greater than 12%; the procedure of low-temperature rolling comprises a second finish rolling stage, andin the second finish rolling stage, a low-temperature high-pressure rolling process is adopted, the initial rolling temperature of a steel plate is 780-820 DEG C, and the finish rolling temperature is760-780 DEG C; and steel is discharged after being rolled and then rapidly enters water to be cooled. By adoption of the production method of the high-quality thick steel plate, the performance of the high-strength and high-tenacity thick steel plate produced through a continuously cast plate is improved, and meanwhile, the technical problems of slow rolling rhythm and low efficiency are solved.

Owner:SHOUGANG CORPORATION

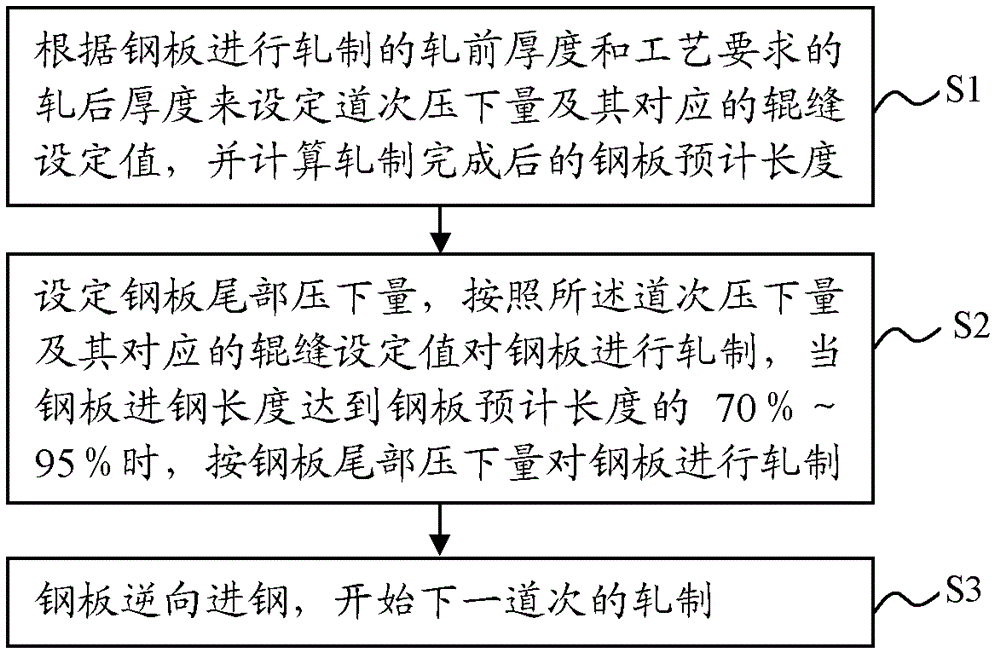

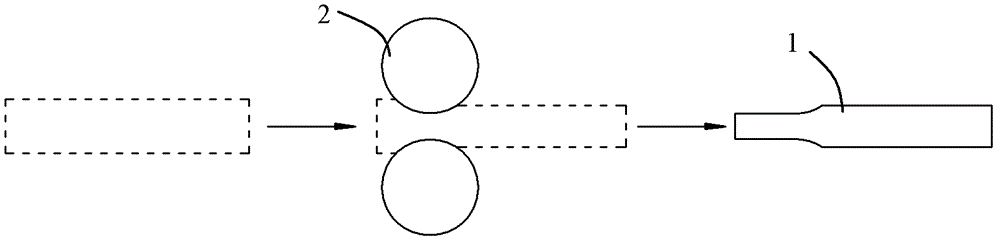

Method for increasing rolling paces of 5m rolling mill

ActiveCN110773570AHigh positioning accuracyImprove tracking accuracyRoll force/gap control deviceMetal rolling arrangementsControl logicMotion control

The invention discloses a method for increasing rolling paces of a 5m rolling mill and belongs to the technical field of steel rolling. The method has the beneficial effects that through optimizationof control logics of a roll gap motion and a roll alternating motion, conversion of a steel rotation code, optimization of a rolling pass, and optimization of tracking of a to-be-rolled position of asteel plate, a steel rotation rolling pass speed and a steel throwing empty pass speed are increased, and an intra-pass steel throwing distance is shortened, so the rolling paces are obviously increased; rolling time spent on each steel plate is reduced by 18.4s on average; and significant effects are realized in increase of production efficiency and reduction of production cost.

Owner:NANJING IRON & STEEL CO LTD

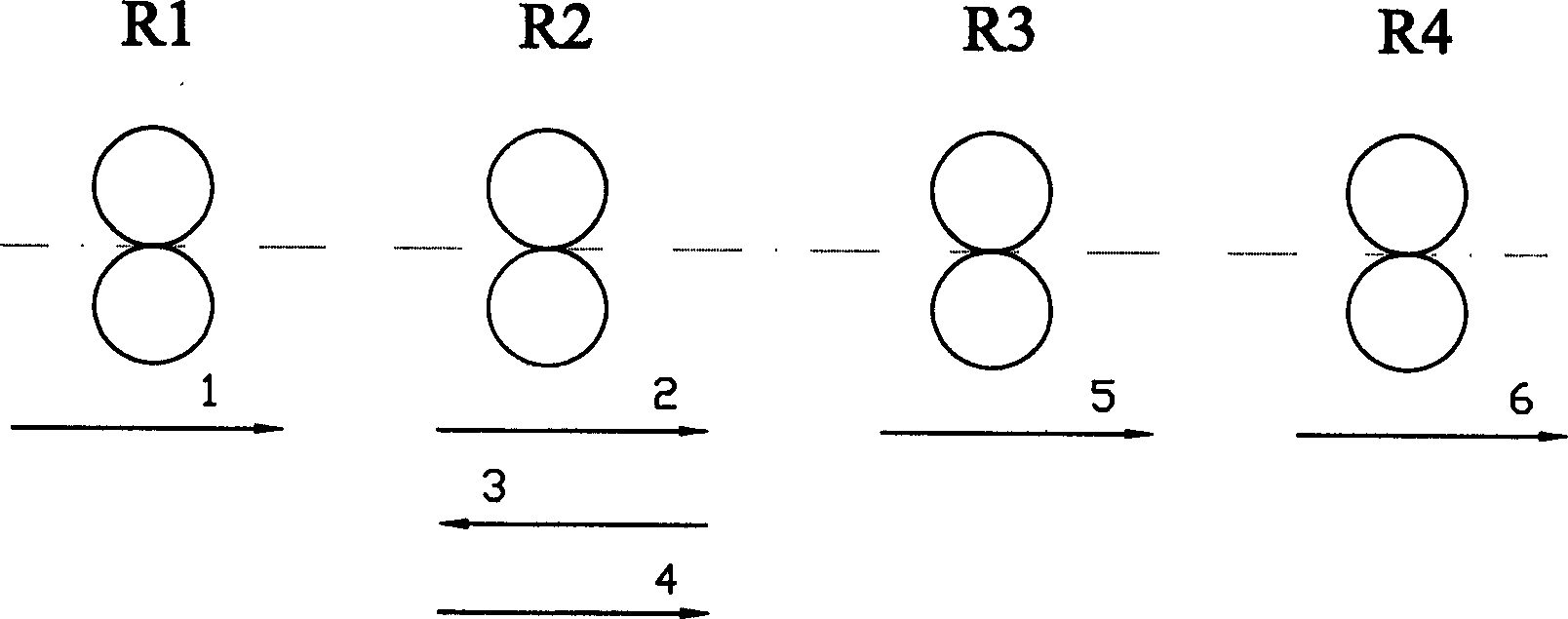

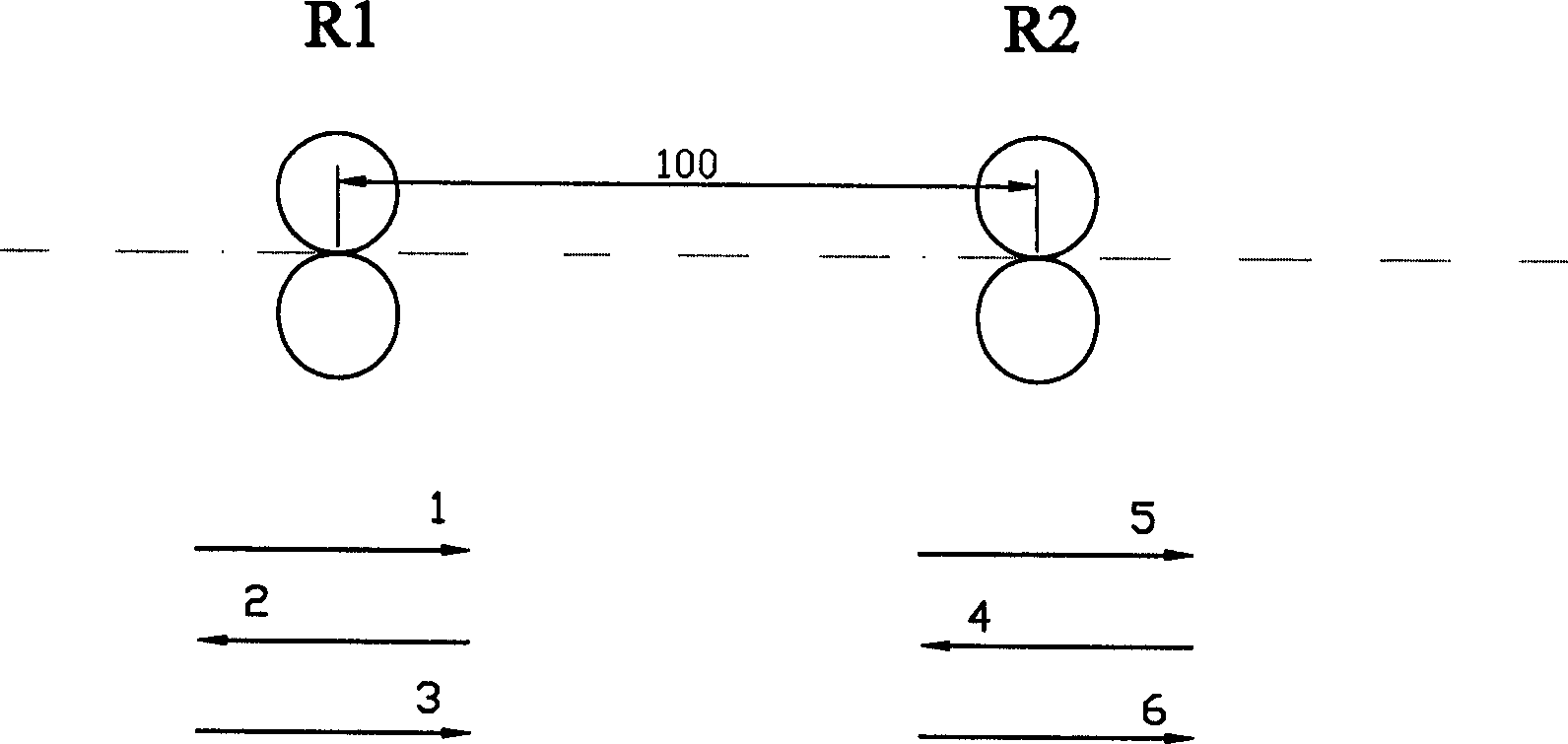

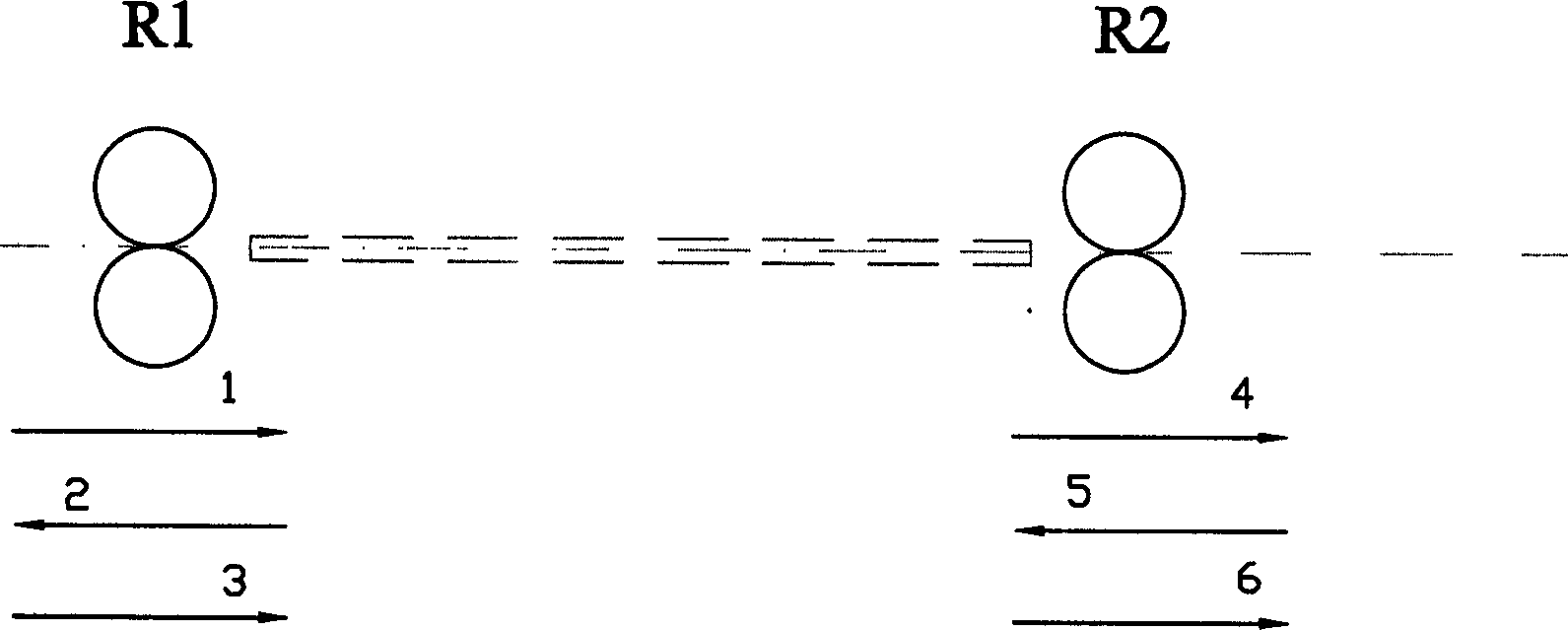

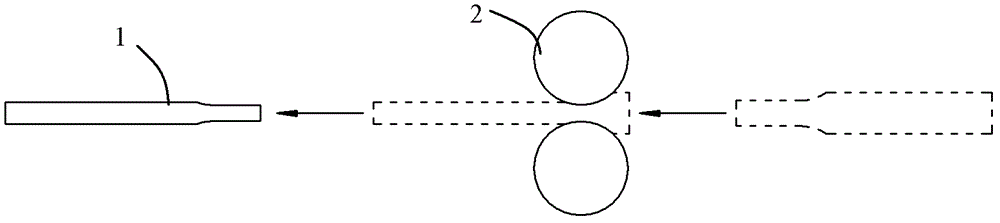

Roughing-rolling reversable mill strand continuous rolling process

InactiveCN1640566AShorten the lengthSave rolling timeGuiding/positioning/aligning arrangementsMetal rolling arrangementsContinuous rollingMaterials science

The present invention relates to a roughing-down reversing rolling mill straightaway and tandem rolling process. It adopts two-stand straightaway setup form, the distance between two reversing rolling mills is 10-70m, the blank can be undergone the straightaway rolling or tandem rolling process of two reversing rolling mills, and its total rolling pass is greater than or equal to even-numbered pass of two passes, in which the initial two passes of the described two stands are straightaway rolling and the final two passes are tandem rolling or straightway rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

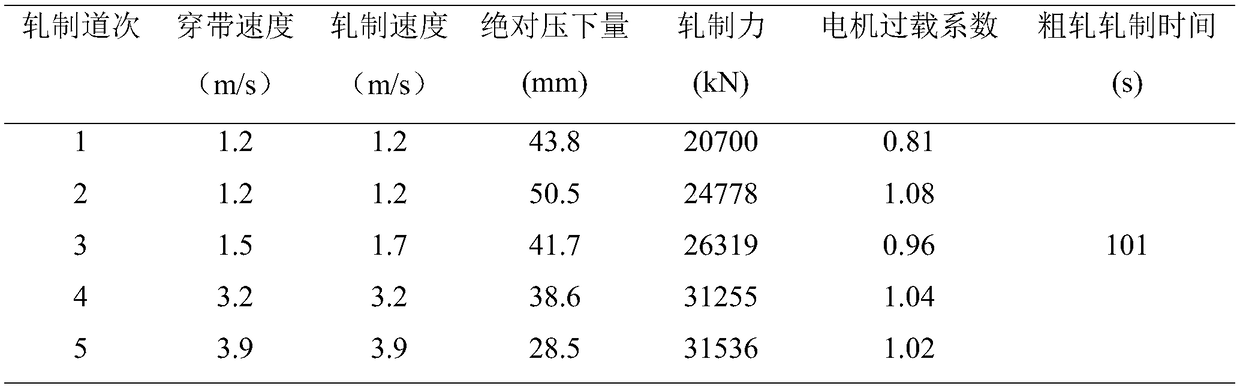

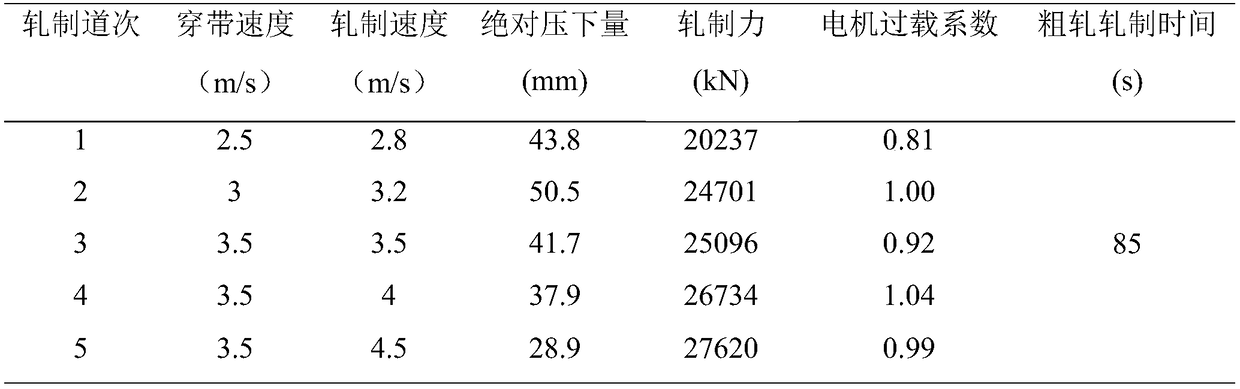

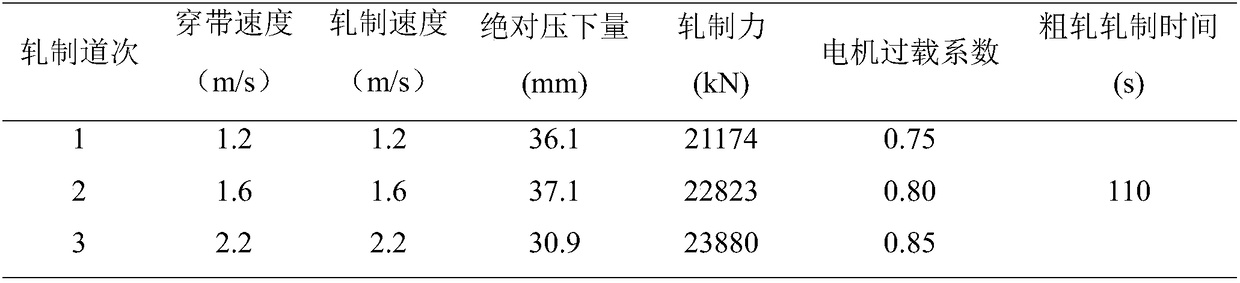

Rolling pacing-improving load distribution method of reversible single-rack four-roller rough rolling mill

ActiveCN109365544ASave rolling timeImprove rolling rhythmRoll speed control devicePower flowLimit value

The invention provides a rolling pacing-improving load distribution method of a reversible single-rack four-roller rough rolling mill. The method comprises the following steps that a single grade of steel is stratified according to the width of plate blanks and total rolling passes of rough rolling, rough rolling setting and calculation parameters are stored, and a rough rolling load distributionmodel is established; the amplitude limiting value of a threading speed of each rough rolling pass is set according to rough rolling passes, wherein the amplitude limiting value of the threading speedof the first pass is 2.5m / s, the amplitude limiting value of the threading speed of the last pass is 4.5m / s, and the difference between the amplitude limiting values of the threading speeds of everytwo adjacent passes is not more than 1m / s; a grade of steel to be treated is provided, data of the rough rolling load distribution model are combined, and the threading speed and the amplitude limiting value of a rolling speed of the single grade of the steel are adjusted so as to satisfy the requirement that when the rolling speed of the steel of the grade is lower than the amplitude limiting value of the threading speed, the threading speed is kept consistent with the rolling speed, when the rolling speed of the steel of the grade is higher than the amplitude limiting value of the threadingspeed, the threading speed is set to be the amplitude limiting value, and meanwhile, when a current of a rough rolling motor is not overloaded, and the rough rolling mill does not slip, the actual rolling speed of the single pass reaches the maximum rolling speed.

Owner:湖南华菱涟源钢铁有限公司

Low welding crack sensitivity, quenching and tempering, high rigid plate and manufacturing method thereof

ActiveCN101476080BGuaranteed continuitySave rolling timeTemperature control deviceFurnace typesForeign matterAustenite

The invention pertaining to the field of low-alloy steel fabrication technique provides low welding crack sensibility quenching and tempering high-strength steel plates and a method for producing the same. The steel plate comprises the following chemical components by quality percent: C of 0.07-0.09%, Si of 0.20-0.40%, Mn of 1.20-1.40%, Alt of 0.30-0.50%, Mo of 0.10-0.20%, V of 0.04-0.06%, Ti of 0.01-0.02%, and Fe and ineluctable foreign matters of the rest; the tissue are secondary troostite and tempering sorbite.Comparing with the two-stage or three-stage rolling, the rolling adopting a austenite perfect recrystallization section has advantages of omitting a temperature-holding stage for assuring the consistency of rolling steel plates and greatly shortening the rolling time of steel blocks on the basis of simplified processes; rolling only in high-temperature regions, therefore, reducing the requirement of the ability of rolling mill equipment and simultaneously shortening the on-rolling time of the steel plates in a high temperature; room-temperature tissue obtained after rolling providing an appropriate tissue base for obtaining homogeneous tissue after quenching and tempering the steel plates.

Owner:SHOUGANG CORPORATION

A cold rolling method capable of preventing edge cracking and brittle fracture of si≥3.5% silicon steel

ActiveCN104399749BImprove magnetismSave rolling timeTemperature control deviceMetal rolling arrangementsEmulsionBrittle fracture

The invention relates to a cold rolling method capable of preventing edge crack and brittle fracture of silicon steel with Si content more than or equal to 3.5 percent. The cold rolling method comprises the steps of firstly preheating an uncoiled steel plate; spraying emulsion and fully closing the flow of the emulsion on the outlet sides of former 1-4 passes; conducting cold rolling by adopting a one-step cold rolling method; coiling, wherein the tension at the starting stage is enabled to be 60-80 percent smaller than the tension under set coiling speed to conduct tension control; conducting subsequent processes according to conventional steps. The cold rolling method capable of preventing edge crack and brittle fracture of silicon steel with Si content more than or equal to 3.5 percent has the advantages that not only can the silicon content be enabled to be more than 3.5 percent to improve the magnetic performance of the silicon steel plate, but also the steel plate can be free of edge cracks during cold rolling, the brittle fracture and reject rate is decreased to 0.15 percent, the rolling time of a single coil can be shortened by no less than 10 minutes, and compared with the prior art, the yield is improved by 28.64 percent.

Owner:武汉钢铁有限公司

Thin-specification RE700MC steel prepared based on fully headless thin slab continuous casting and rolling process and preparation method thereof

InactiveCN108796189ADimensionally stableHigh degree of spheroidizationFurnace typesHeat treatment furnacesMetallurgyContinuous rolling

The invention discloses thin-specification RE700MC steel prepared based on a fully headless thin slab continuous casting and rolling process and a preparation method of the thin-specification RE700MCsteel. The RE700MC steel is prepared from, by mass, 0.04%-0.06% of C, 0.15%-0.50% of Si, 1.3%-1.8% of Mn, 0.02%-0.04% of Als, 0.010%-0.06% of Nb, 0.04%-0.13% of Ti, 0.0020% or less of S, 0.012% or less of P, 0.005% or less of N and the balance Fe. The product thickness of the RE700MC steel is 1.0mm-3.5mm. The preparation method comprises the working procedures of raw material selection, convertersmelting, LF refining furnace refining, RH refining furnace refining, continuous casting, continuous rolling, induction furnace heating, finish rolling, cooling and curling. The RE700MC steel in the scheme has the advantages that mechanical performance is excellent, the plate size is stable, the inclusion spheroidization degree is high, and the microscopic structure is excellent. Meanwhile, the preparation method is short in technological process, low in energy consumption and cost and stable in product performance.

Owner:RIZHAO STEEL HLDG GROUP

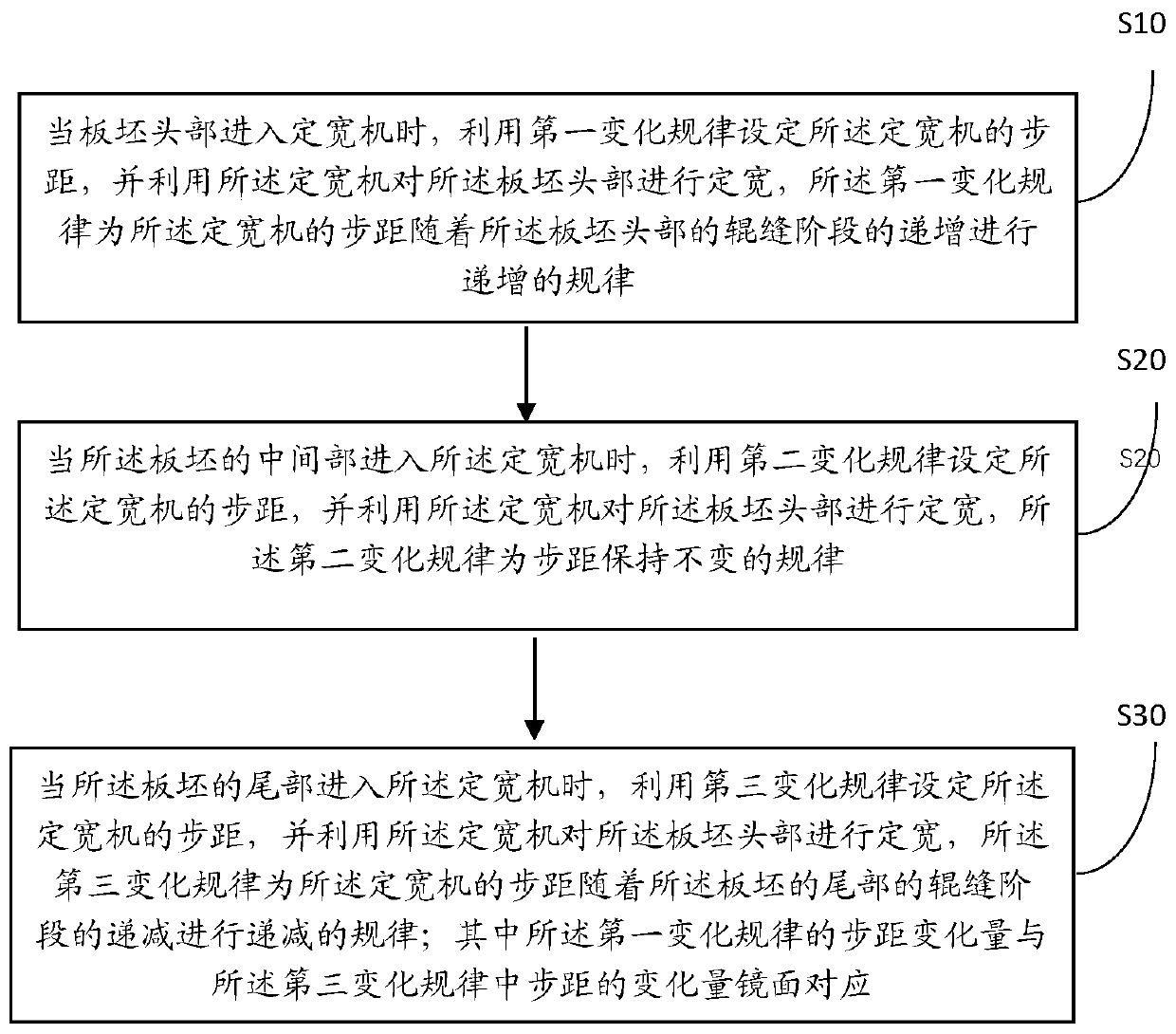

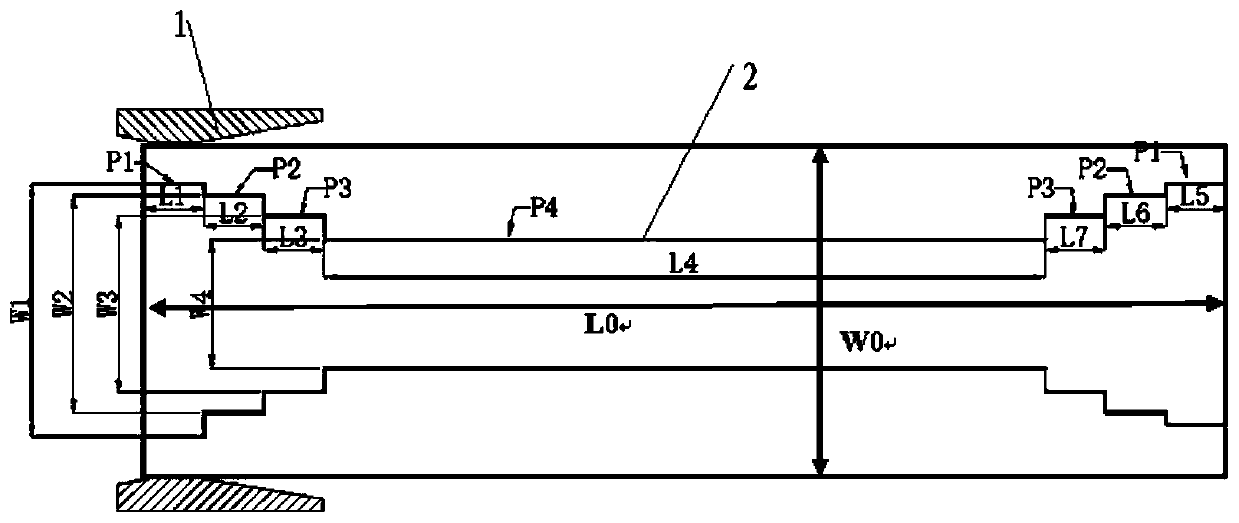

Variable step pitch head-tail width control method of fixed width machine

ActiveCN109821901AReduce the temperatureSave rolling timeMetal rolling stand detailsPulp and paper industryFirst variation

The invention provides a variable step pitch head-tail width control method of a fixed width machine. The method comprises the steps that the step pitch of the fixed width machine is set according toa first variation rule when the head of a plate blank enters the fixed width machine, and the first variation rule means that the step pitch of the fixed width machine is increased with the roll gap of the head of the plate blank in a staged mode; when the middle portion of the plate blank enters the fixed width machine, the width of the head of the plate blank is fixed through the fixed width machine, and the step pitch is constant according to a second variation rule; when the tail of the plate blank enters the fixed width machine, the step pitch of the fixed width machine is set in accordance with a third variation rule, and the third variation rule means that the step pitch is decreased in a multi-staged mode; and the variation amounts of all the stage of the first variation rule and the third variation rule are in mirror symmetry. The method achieves the technical effects that through layered control over the step pitch of the fixed width machine, the problem that the head end andthe tail end of metal of steel with high hardness level and widened amount are not restrained, and consequently width reduction is caused is effectively solved, the width control precision of the fixed width machine is effectively improved, and the product yield is increased.

Owner:BEIJING SHOUGANG CO LTD

Titanium blank rough rolling method of ordinary hot rolling mill

ActiveCN102069091AQuality assuranceQuality improvementRoll force/gap control deviceMetal rolling arrangementsStrip millTitanium

The invention relates to a titanium blank rough rolling method of an ordinary hot rolling mill, which can effectively ensure the quality of rough rolled intermediate titanium blanks. In the method, titanium blanks with the thicknesses H of 100-200mm are rough rolled, and before rough rolling is performed, a rough rolling technology of the titanium blanks is firstly determined according to the thickness H of the titanium blank, the technology includes rough rolling passes N, and the rolling openness and rolling reduction of each pass, and in the rolling process, the rolling openness of the rolling mill of each pass keeps constant. The method can keep the quality of the intermediate titanium blanks stable, and makes the shape of the intermediate titanium blank similar to a rectangle, and the shapes of the head part and the tail part similar to a sled.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

A Method of Improving the Rolling Rhythm of 5-meter Rolling Mill

ActiveCN110773570BHigh positioning accuracyImprove tracking accuracyRoll force/gap control deviceMetal rolling arrangementsThermodynamicsMechanics

The invention discloses a method for increasing rolling paces of a 5m rolling mill and belongs to the technical field of steel rolling. The method has the beneficial effects that through optimizationof control logics of a roll gap motion and a roll alternating motion, conversion of a steel rotation code, optimization of a rolling pass, and optimization of tracking of a to-be-rolled position of asteel plate, a steel rotation rolling pass speed and a steel throwing empty pass speed are increased, and an intra-pass steel throwing distance is shortened, so the rolling paces are obviously increased; rolling time spent on each steel plate is reduced by 18.4s on average; and significant effects are realized in increase of production efficiency and reduction of production cost.

Owner:NANJING IRON & STEEL CO LTD

Efficient rolling method for steel plate

InactiveCN111330975ASave rolling timeReduce wasteMetal rolling arrangementsWater coolingIndustrial engineering

The invention discloses an efficient rolling method for a steel plate. According to the method, intermediate blanks rolled for a plurality of passes are rapidly cut and segmented on line, then a plurality of small intermediate blanks obtained after cutting are rolled into finished products, different rolling technologies can be adopted for rolling the finished products of different sizes and specifications, and therefore the purposes of one-plate multi-rolling and efficient rolling are achieved. The method specifically comprises the steps that after plate blanks are rolled for the plurality ofpasses into the intermediate blanks, the plate blanks are rapidly cut into N small intermediate blanks (N is larger than or equal to 2) on line; and the finished products are rolled according to theneeded rolling technology, the rolled finished products can be subjected to water cooling or air cooling on a cooling bed, and then heat treatment is carried out according to the performance requirement. By means of the method, the cogging material rolling time is saved to a great extent, the rolling cost is reduced, and the method can be used for laboratory rolling experiments or medium and thickplate workshop site steel rolling production.

Owner:湖南卡密尔新材料科技有限公司

Long-distance-leaving steel billet positioning control system for roughing mill

InactiveCN107350293ASimple designEasy to implementRoll mill control devicesMeasuring devicesMetallurgyOperation mode

The invention discloses a steel running positioning control system for a blanking machine, which specifically includes: a roller table, an entrance turning machine, a blanking machine, an entrance push bed, an entrance hot metal detector, an exit hot metal detector, and an exit push bed; The entrance hot metal detector is connected with the roller table, and the speed of the roller table is controlled by the detected hot metal signal, so that the billet is decelerated on the roller table; the outlet hot metal detector is located on the rear working roller table of the entrance detector, It is connected with the blanking machine and the roller table, and is characterized in that the operation of the main motor roller table of the blanking machine is controlled by the loss of the steel bite signal of the blanking machine frame during the rolling process. Beneficial effects of the present invention: the design is simple and easy to implement; through the control of the rolling speed of the billet mill and the control of the operation mode of the roller table, the distance from which the billet rushes out of the rack of the billet mill can be precisely controlled; Control time, so as to achieve the purpose of speeding up the production rhythm, ensuring steel temperature and saving energy.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Method for producing medium-thickness steel for engineering machinery by single-stand steckel mill

PendingCN112676344AReduced incidence of pitting defectsReduce energy consumptionWork treatment devicesMetal rolling arrangementsHeating furnaceIndustrial engineering

The invention discloses a method for producing medium-thickness steel for engineering machinery by a single-stand steckel mill. The surface quality of a steel plate is improved by improving heating, rolling and descaling processes, and a low-temperature heating mode is adopted to heat a steel billet, reduces the occurrence rate of pitted surface defects of the steel plate in a heating link, reduces defects caused by the fact that oxide scales are pressed into the surface of the steel plate in the rolling process, reduces the heating furnace energy consumption and the production cost, and improves the production efficiency.

Owner:NANJING IRON & STEEL CO LTD

A single-stand reversing rolling mill ultra-thin steel strip rolling process

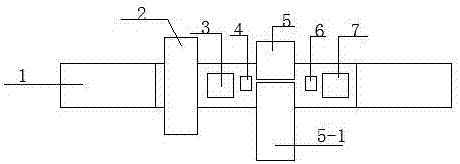

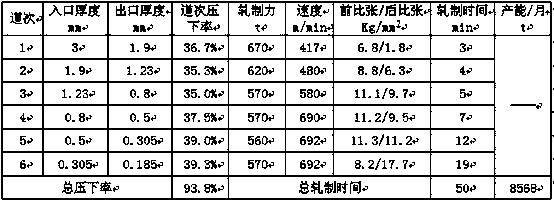

ActiveCN108284133BImprove product qualityReduce loadMetal rolling arrangementsEngineeringStrip steel

The invention relates to a technological method for rolling an ultrathin steel strip on a single-stand reversible rolling mill. The method is characterized in that hot rolled strip steel with the thickness of 2.75 to 3.0 mm is used as a raw material, and the 1150 rolling mill with the rolling force of 9000 KN is used for rolling the ultrathin steel strip with the thickness of 0.13-0.2 mm through six-pass rolling. According to the technological method for rolling the ultrathin steel strip on the single-stand reversible rolling mill, the state of an emulsion is adjusted, so that rolling passes are compressed, the rolling reduction rate is increased, the tension method is improved, high-speed rolling of the ultrathin steel strip is realized, working time is shortened, and productivity and efficiency of the rolling mill are greatly improved; and the ultrathin steel strip rolled by the method is good in plate shape, meets the requirements in thickness, is stable in quality, can meet the requirements for the thickness of the ultrathin plate of the industries, such as food packaging, chemical engineering, household electrical appliance panels, electronic information and color-coated galvanized plates and can be applied to production in a large scale.

Owner:邯郸市金泰包装材料有限公司

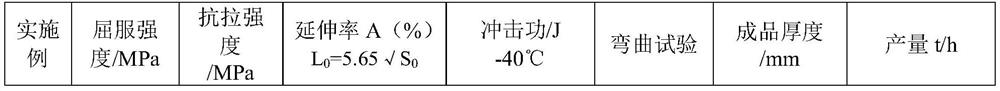

Production method of thick-specification steel S355G11M hot rolled coil for seaside building structure

InactiveCN112695251ASave rolling timeImprove organizationManufacturing convertersProduction lineAlloy

The invention provides a production method of a thick steel S355G11M hot rolled coil for a seaside building structure. According to the method, in the chemical composition and production process design of an FTSR production line S355G11M, a Cr-Nb-Ti composite strengthening means is adopted for replacing precious alloys such as Mo, Ni and V, and a hot continuous rolling unit for producing a hot-rolled coil plate is used for replacing a medium plate production mode of a traditional reversible rolling mill; and the hot-rolled coiled plate produced by the hot continuous rolling unit is used for replacing a medium-thickness plate with the same thickness specification, so that the purposes of improving the production efficiency and reducing the cost are achieved while high strength and good toughness are achieved.

Owner:BENGANG STEEL PLATES

A kind of high-strength light-weight h-shaped steel and its hot rolling forming process

ActiveCN111468534BHigh strengthReduce weightElongated constructional elementsWork heating devicesHigh pressure waterUltimate tensile strength

The invention discloses a high-strength light-weight H-shaped steel, which comprises a web and a wing, the height of the web is 146 mm, the thickness of the web is 3.3 mm, the width of the wing is 95 mm, and the thickness of the wing is 4.0 mm; the H-shaped steel is hot-rolled and formed The process is as follows: the heated square steel billet is descaled by high-pressure water, rough-rolled by two three-roller transverse rolling mills, and then subjected to head-cutting treatment, and then rolled back and forth for 4-6 passes by a universal rough-rolling unit, and finally passed through The universal finishing rolling unit reciprocates rolling for 1-2 passes, and the rolled piece is air-cooled by the cooling bed and then cut to a fixed length to obtain the finished product; the invention can make the rolled H-shaped steel have the same height H and width B as the standard H-shaped steel Under normal circumstances, it has a smaller web thickness and wing thickness, and can guarantee its strength; in the rolling process, the number of rough rolling passes is significantly reduced, the rolling time is shortened, and the temperature drop of the rolled piece is small. The product quality is guaranteed, while the rolling production speed is accelerated, and the production efficiency is improved.

Owner:山东德坊新材料科技有限公司

Multi-rolling device for LED soft light bars

InactiveCN106672668ASave rolling timeIncrease productivityArticle deliveryWebs handlingManipulatorEngineering

The invention relates to a multi-rolling device for LED soft light bars. The multi-rolling device comprises a support, a light belt pulling-out and layering mechanical arm, a light belt feeding rolling disc mechanical arm and a light belt rolling-up rolling disc rotating machine. The support comprises a first supporting arm and a second supporting arm. Guide rails are arranged on the first supporting arm and the second supporting arm. The light belt pulling-out and layering mechanical arm is arranged in the guide rail of the first supporting arm and can move in the guide rail in a reciprocating manner. The light belt feeding rolling disc mechanical arm is installed in the guide rail of the second supporting arm and can move in the guide rail in a reciprocating manner. The light bar rolling-up rolling disc rotating machine comprises a base, a rotating position rolling-up part, a motor, a rotating shaft and a rolling disc. By the adoption of the structure, equipment and cutting equipment in the previous process are used in cooperation in the LED multi-rolling device, and 30 light bars cut in the previous process can be rolled at a time. The rolling time is greatly saved, and the production efficiency is improved.

Owner:广东三泰迈高光电科技有限公司

Preparation method of wide alloy plate

ActiveCN113913648AImprove flatnessLarge formatRoll force/gap control deviceMetal rolling arrangementsSuperalloyLarge deformation

A preparation method of a wide alloy plate comprises the following steps that a high-temperature alloy plate blank is subjected to first-fire rolling at the temperature of 1130-1150 DEG C and then subjected to material separation, then subjected to second-fire rolling at the temperature of 1130-1150 DEG C and then subjected to material separation, then subjected to third-fire rolling at the temperature of 1050-1080 DEG C and finally subjected to solid solution leveling treatment; wherein the total deformation of the first-fire rolling is 45%-55%, and the total deformation of the second-fire rolling is 45%-55%; and the total deformation of the third-fire rolling is 60-80%. According to the method, a multi-heating-number and multi-pass forming mode is adopted, firstly, small-deformation cogging is adopted, deformation resistance is reduced, the requirement for equipment is reduced, large-deformation reversing rolling is conducted after cogging is completed, all consistency of the plate structure is improved, and the structure uniformity and performance uniformity of the plate are guaranteed.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

Forced rolling mill feed device

ActiveCN103252362BOperational securityEasy to operateMetal rolling arrangementsStrip millWorking environment

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

An Optimal Controlled Rolling Method Using Ultra-rapid Cooling to Control Austenite Structure

At present, the ultra-rapid cooling technology is mainly applied to cooling steel after two-stage controlled rolling. The invention discloses an optimized controlled rolling method using ultra-rapid cooling to control the austenite structure, which belongs to the technical field of metallurgy. This method rolls the steel completely in the austenite recrystallization zone of the billet, and at the same time precisely controls the rolling temperature and pass reduction rate. Immediately after rolling, the rolled steel is cooled to the phase transformation point by an ultra-fast cooling system, and then According to the needs, different cooling paths are used to control the phase transformation of steel. The invention adopts ultra-rapid cooling to effectively suppress the coarsening of fine recrystallized austenite structure, and retains the effect of dynamic recrystallization and sub-dynamic recrystallization on the refinement of austenite structure in the high-temperature rolling process. The product manufactured by the present invention has comparable mechanical properties to the steel produced by the two-stage controlled rolling process, and at the same time reduces the waiting temperature and low temperature and high pressure in the rolling process, and reduces the rolling time by 2 to 4 minutes compared with the two-stage controlled rolling process. .

Owner:NORTHEASTERN UNIV LIAONING

Rolling method capable of improving biting condition in rolling process of reversible rolling mill

ActiveCN103203358BLarge amount of depressionLower the roll gap positionMetal rolling arrangementsProduction rateEnergy consumption

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com