Patents

Literature

82results about How to "Avoid Surface Quality Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

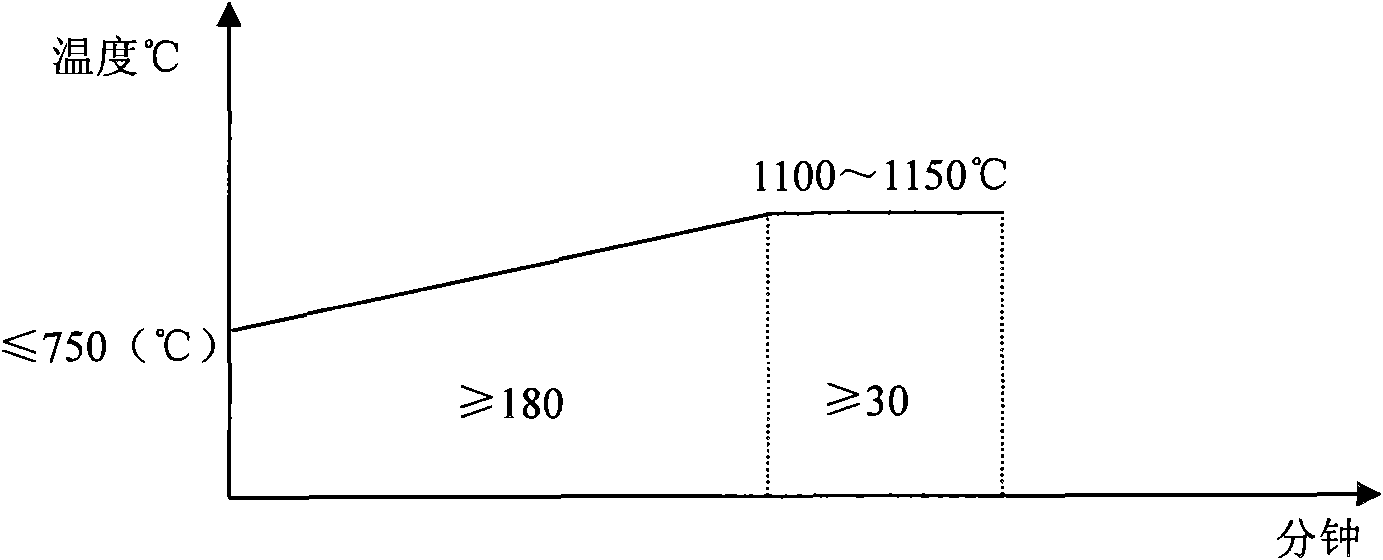

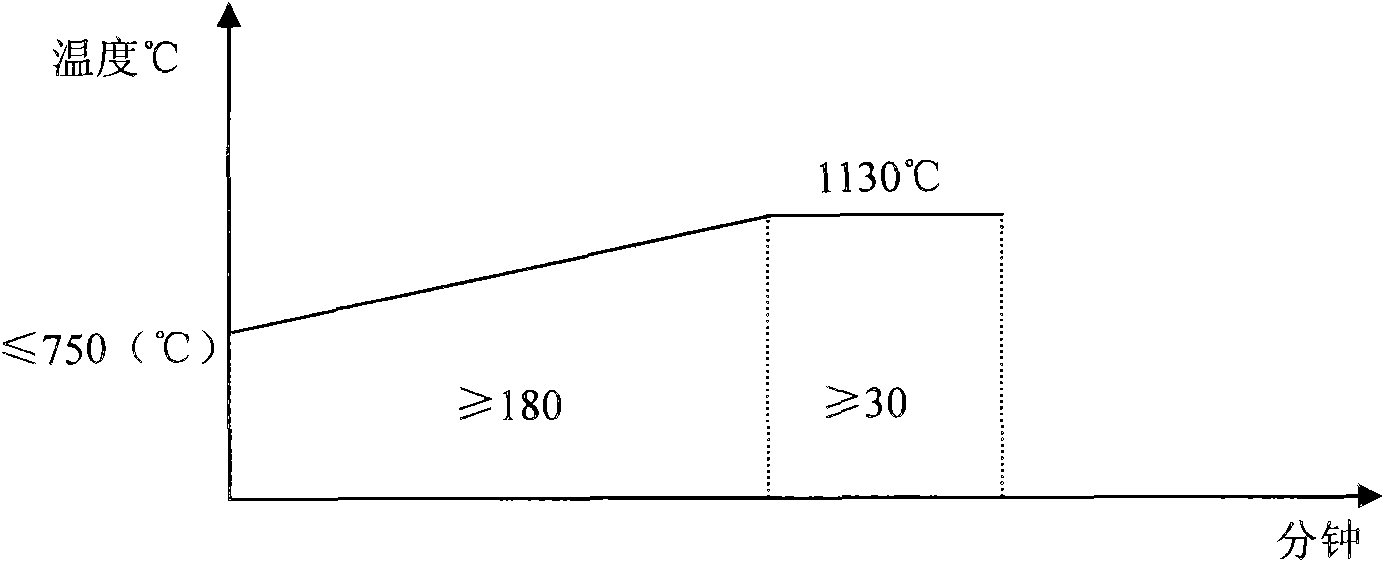

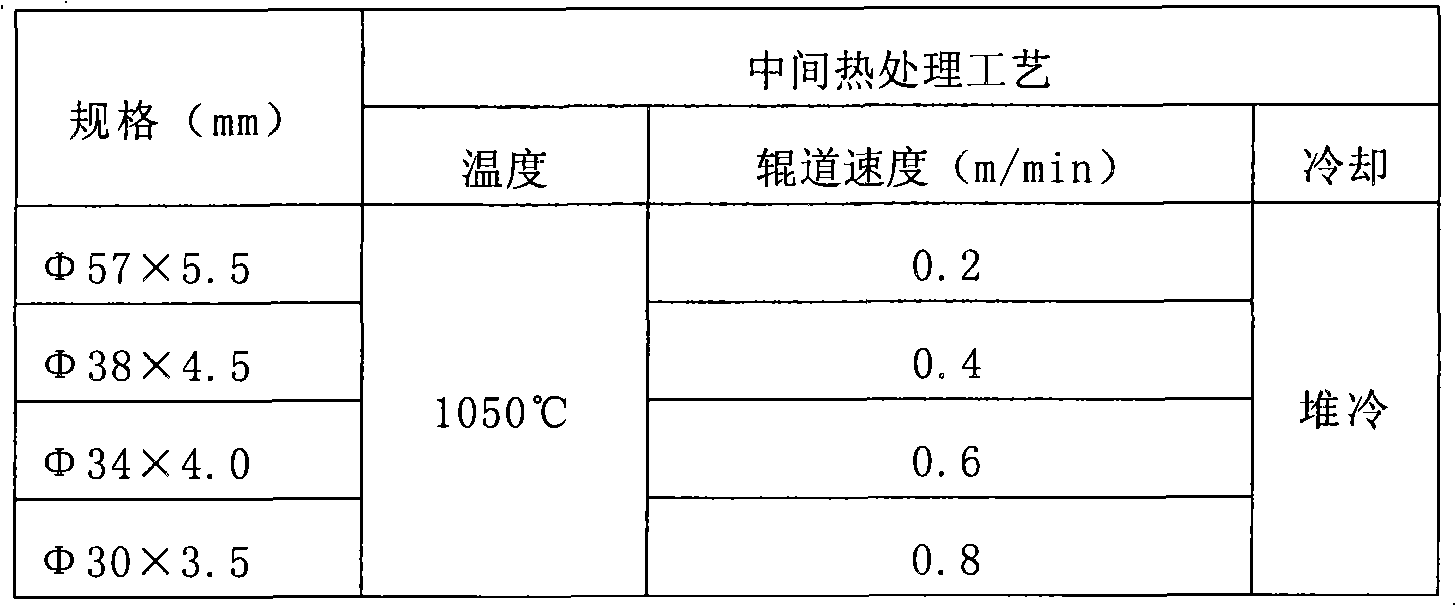

Method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel

InactiveCN101612700AAvoid Surface Quality IssuesReduce lossFurnace typesMetal rolling arrangementsSolution treatmentProduct inspection

The invention discloses a method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel, which comprises the following steps of billets, peeling, blanking, heating, hot punching, cooling, finishing, acid cleaning, lubricating, degreasing, heat treatment, straightening, tube cutting, acid cleaning, inspection, and packaging and warehousing. Compared with the prior art, the method has the following advantages that: pierced billets after hot punching are cooled in a pile so as to reduce working procedures and cost; the intermediate heat treatment adopts solution treatment, has short time and high efficiency, and improves surface quality; the tubes all adopt cold rolling process to improve yield; and vacuum aging treatment is adopted to improve the comprehensive mechanical property, the finished product inspection qualified rate reach 95 percent, and the yield from the billets to the finished products reach 51.31 percent.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

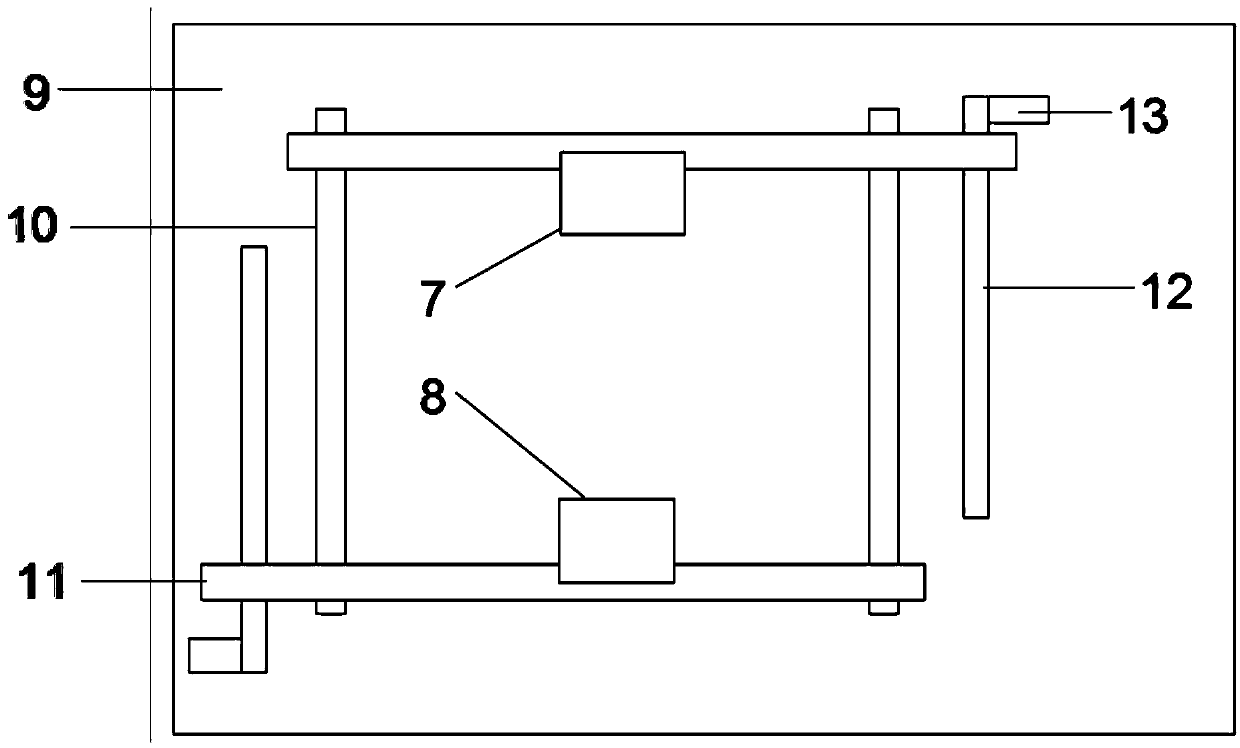

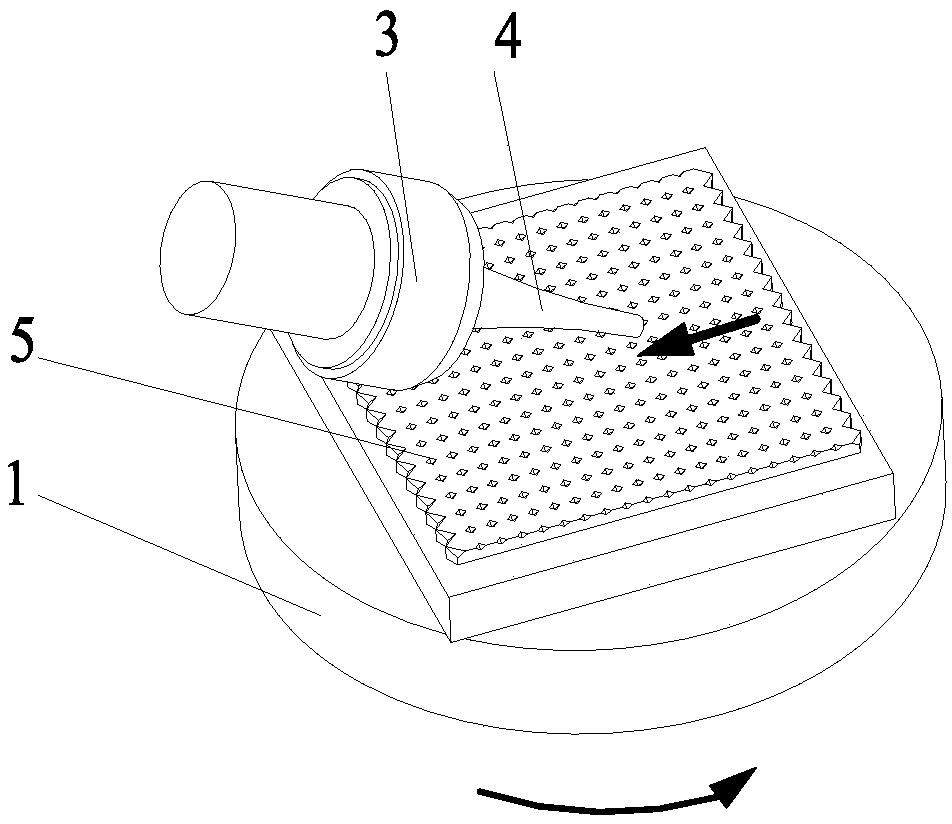

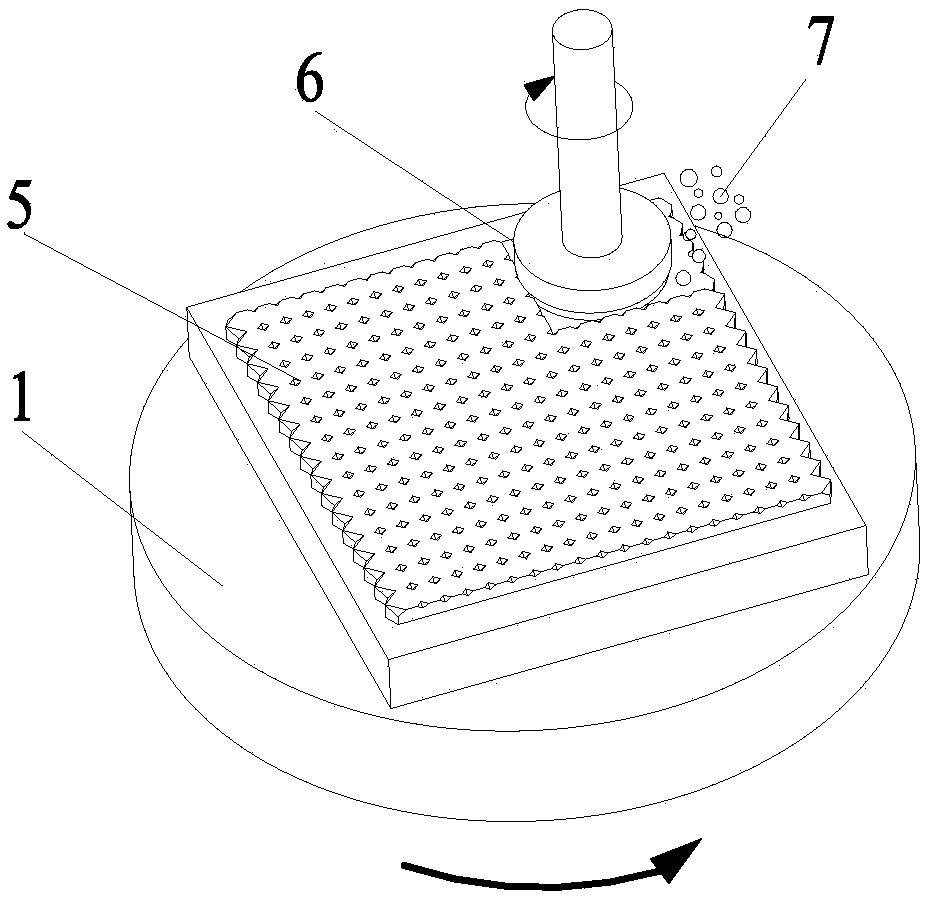

Method and device for manufacturing efficient and high-precision composite additive

ActiveCN104190931AShorten forming timeImprove forming efficiencyIncreasing energy efficiencyLight beamMetal powder

The invention discloses a method and device for manufacturing efficient and high-precision composite additive, and the method and device are achieved through composition of a laser beam and an electron beam. In the process of the action of a high energy beam and metal powder, metal powder of a surface outline is scanned and molten through the laser beam, and the surface of a part has a good surface quality. The electron beam melts the internal powder at a high speed to form a part inner cavity so as to reach the highest forming efficiency. The lower portion of the device comprises a powder laying roller, a workbench, a powder conveying cylinder and a working cylinder. The upper portion of the device comprises an electron beam generating device, a laser beam generating device, a bottom plate, two guide rails, two beams, a synchronous belt wheel and a servo motor. The electron beam generating device and the laser beam generating device are respectively integral and move to the forming area alternately to carry out scanning. By means of the method and device, the defects in the single forming technology can be overcome, and the purposes of reasonably controlling the formed microstructural organization and optimizing the comprehensive performance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

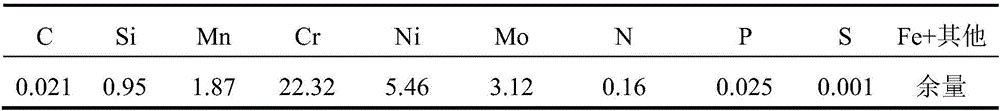

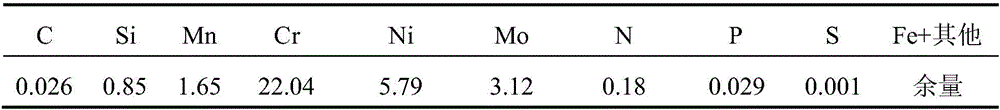

Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

InactiveCN106391704AQuality improvementNo crackWork treatment devicesMetal rolling arrangementsReduction rateMetallurgy

The invention belongs to the technical field of stainless steel rolling, and particularly discloses a method for eliminating cracks of a hot processed surface of a 2205 dual-phase stainless steel middle plate. The method is characterized by comprising the steps that blank selection and grinding are carried out; a cast blank is heated, specifically, the temperature of a preheating section is 1100-1150 DEG C, the temperature of a heating section is 1150-1240 DEG C, the temperature of a soaking section is 1220-1240 DEG C, and for every 10 mm of the cast blank thickness, the furnace standing time is 9-10 min; scale removal is carried out with water of high pressure of 20-25 MPa; the initial rough rolling temperature is higher than 1150 DEG C, the reduction rate is smaller than 25%, rolling is carried out for 8-11 passes, and the thickness of an intermediate blank is 35-45 mm; and the initial finish rolling temperature is larger than 1050 DEG C, the final rolling temperature is larger than 950 DEG C, the reduction rate is smaller than 18%, and rolling is carried out for 8-12 passes. The method has the advantages that the blank specifications are selected reasonably, parameters such as rolling temperature and reduction rate are matched reasonably after grinding and optimal heating, and the surface crack defect of the 2205 dual-phase stainless steel middle plate is effectively avoided.

Owner:NORTHEASTERN UNIV

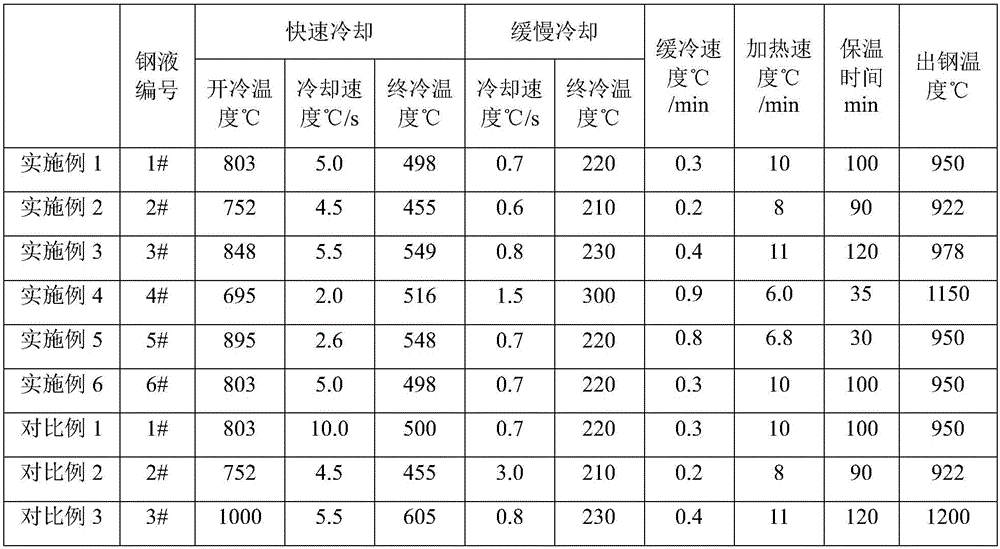

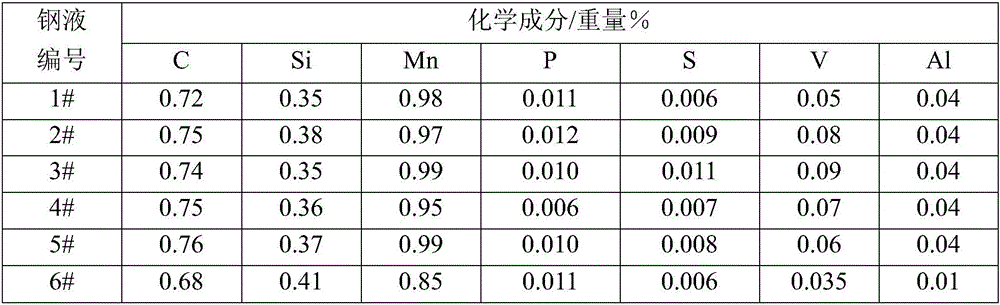

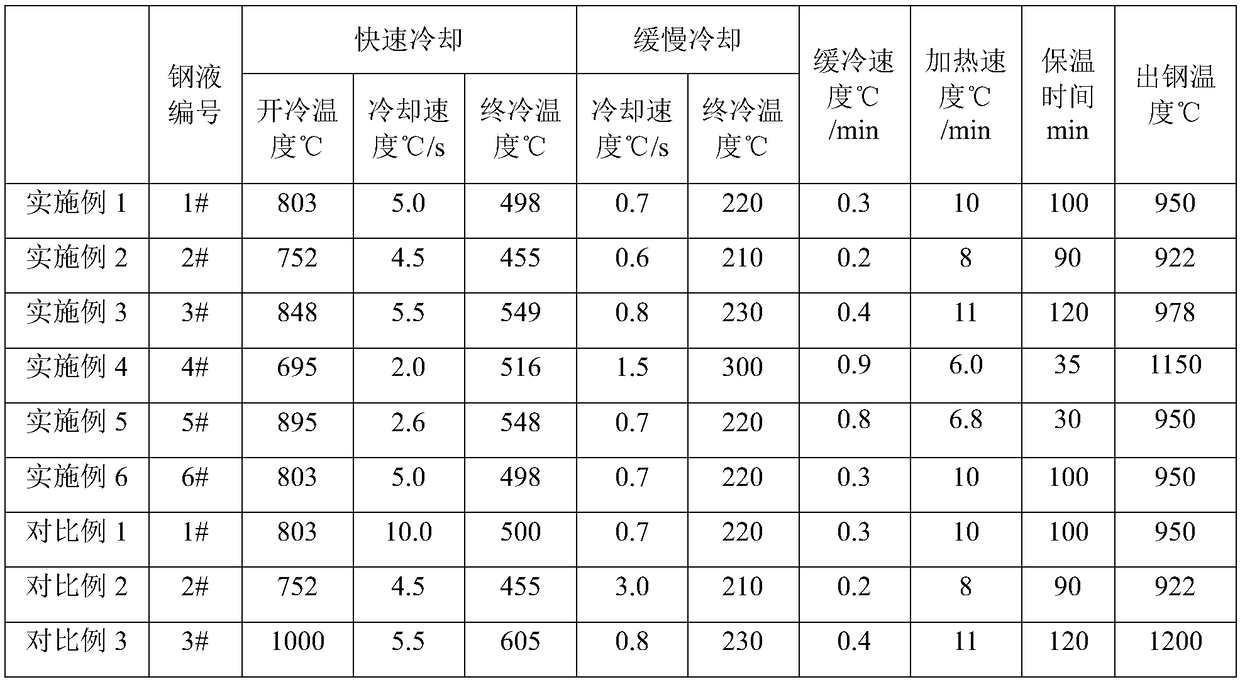

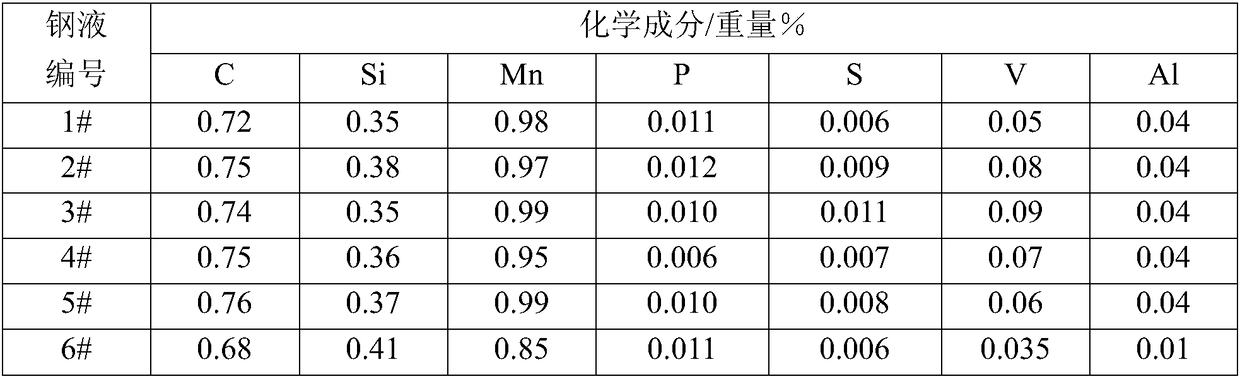

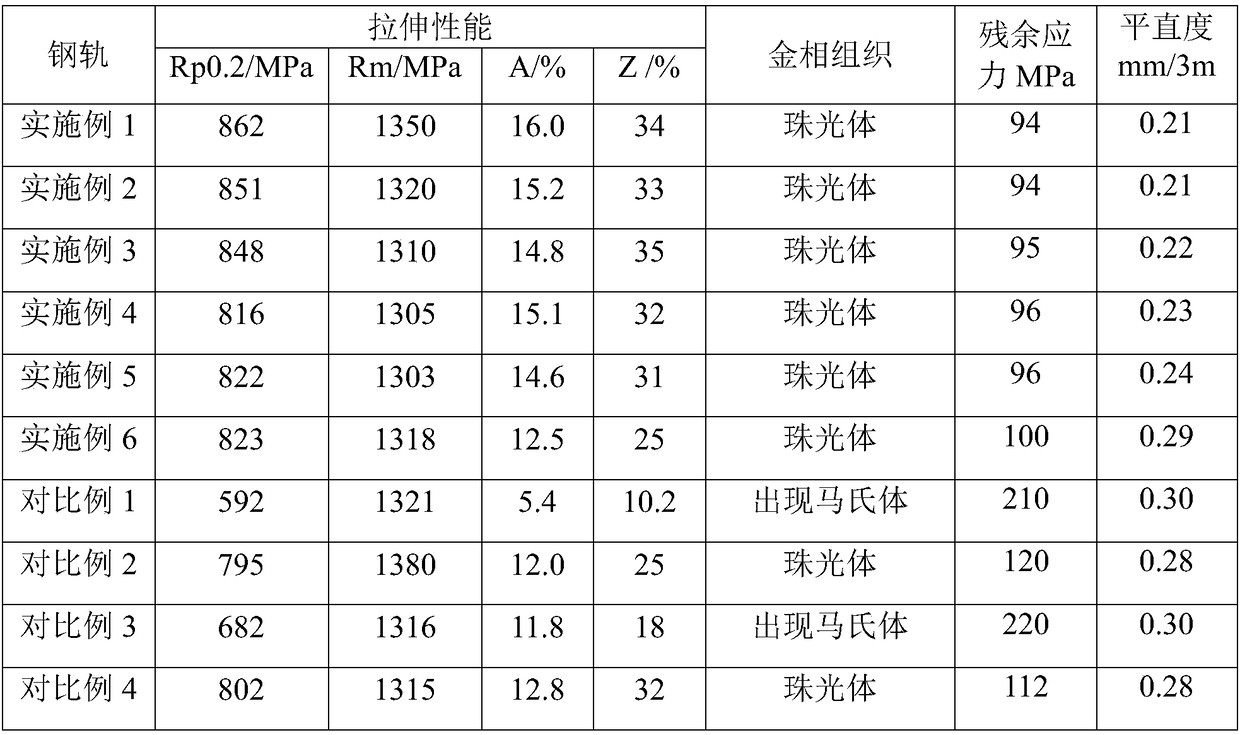

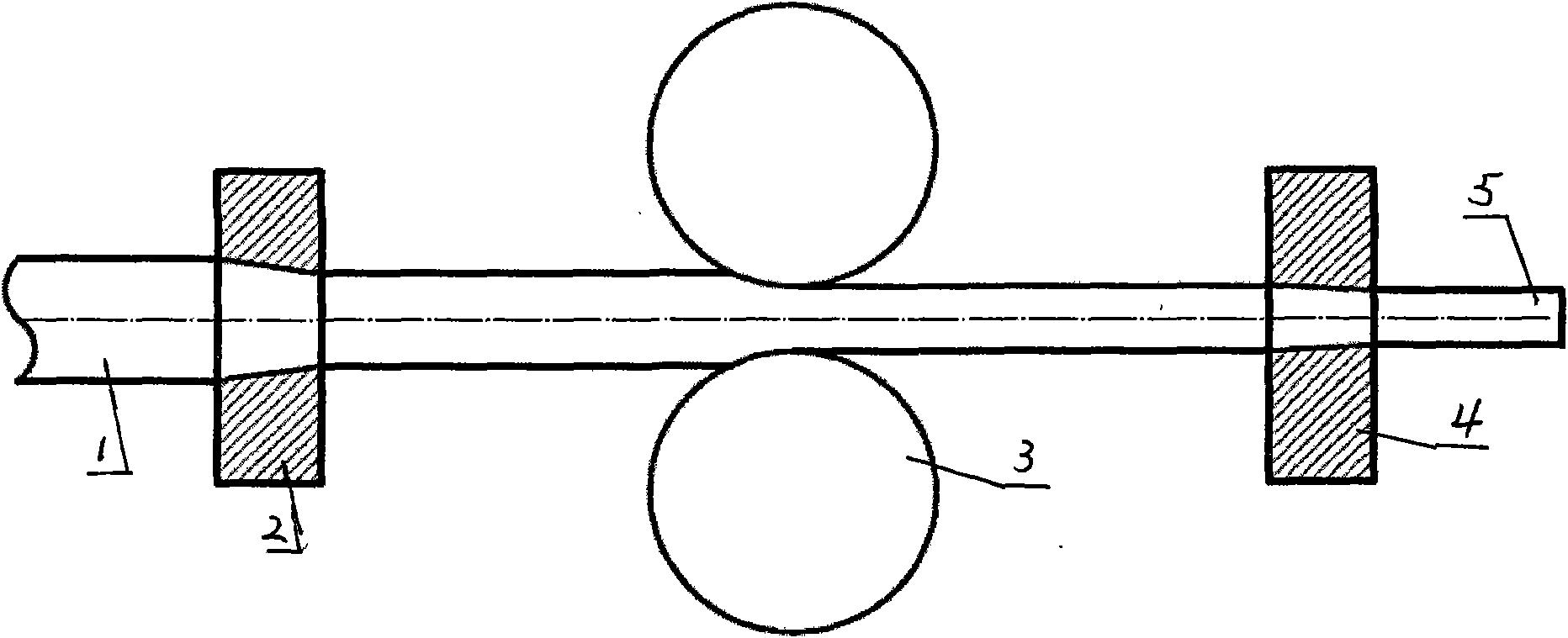

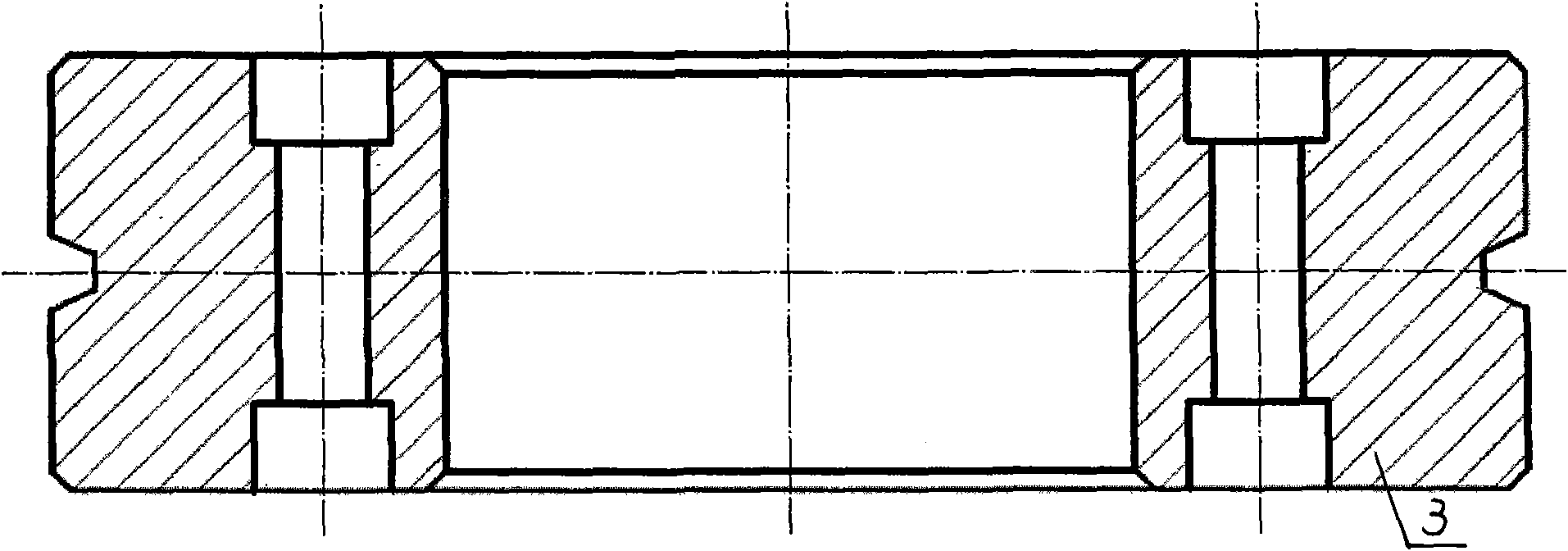

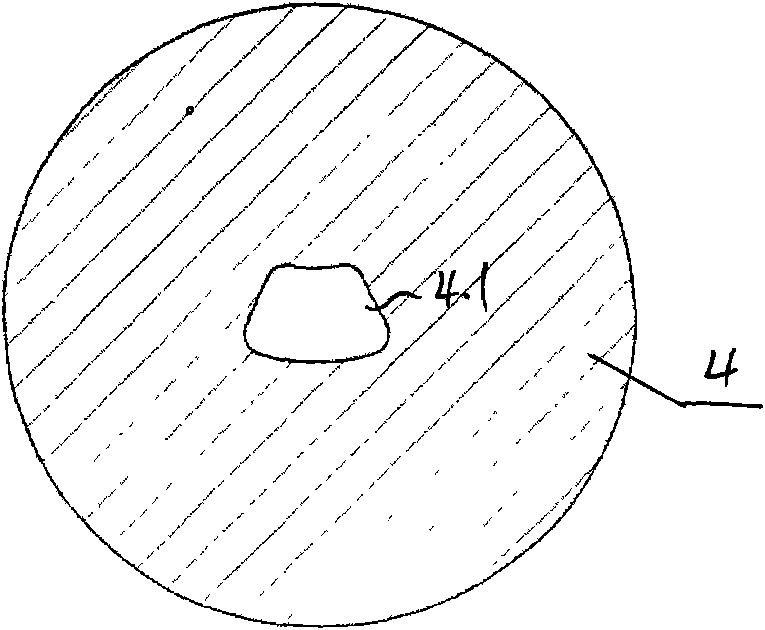

Method for reducing residual stress of steel rail, obtained steel rail and application of steel rail

ActiveCN106086370AReduce residual stressImprove straightnessRailsFurnace typesSlow coolingCooling temperature

The invention relates to the field of steel making, in particular to a method for reducing the residual stress of a steel rail, the steel rail obtained according to the method, and the application of the steel rail. The method for reducing the residual stress of the steel rail comprises the step of sequentially carrying out accelerated cooling, slow cooling and air cooling on the rail head tread centers, the two sides of each rail head and the center part of the rail base of the steel rail obtained after rolling, wherein the starting cooling temperature of accelerated cooling is 650 DEG C to 950 DEG C, the cooling rate of accelerated cooling is 2 DEG C per second to 8 DEG C per second, the finish cooling temperature of accelerated cooling is 400 DEG C to 600 DEG C, the cooling rate of slowing cooling is 0.1 DEG C per second to 1.5 DEG C per second, and the finish cooling temperature of slow cooling is 180 DEG C to 300 DEG C. With the method for reducing the residual stress of the steel rail, on the premise that the tensile property of the steel rail is guaranteed, the residual stress of the steel rail can be effectively reduced, and the flatness of the steel rail can be improved. The steel rail is particularly suitable for high-speed railways.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

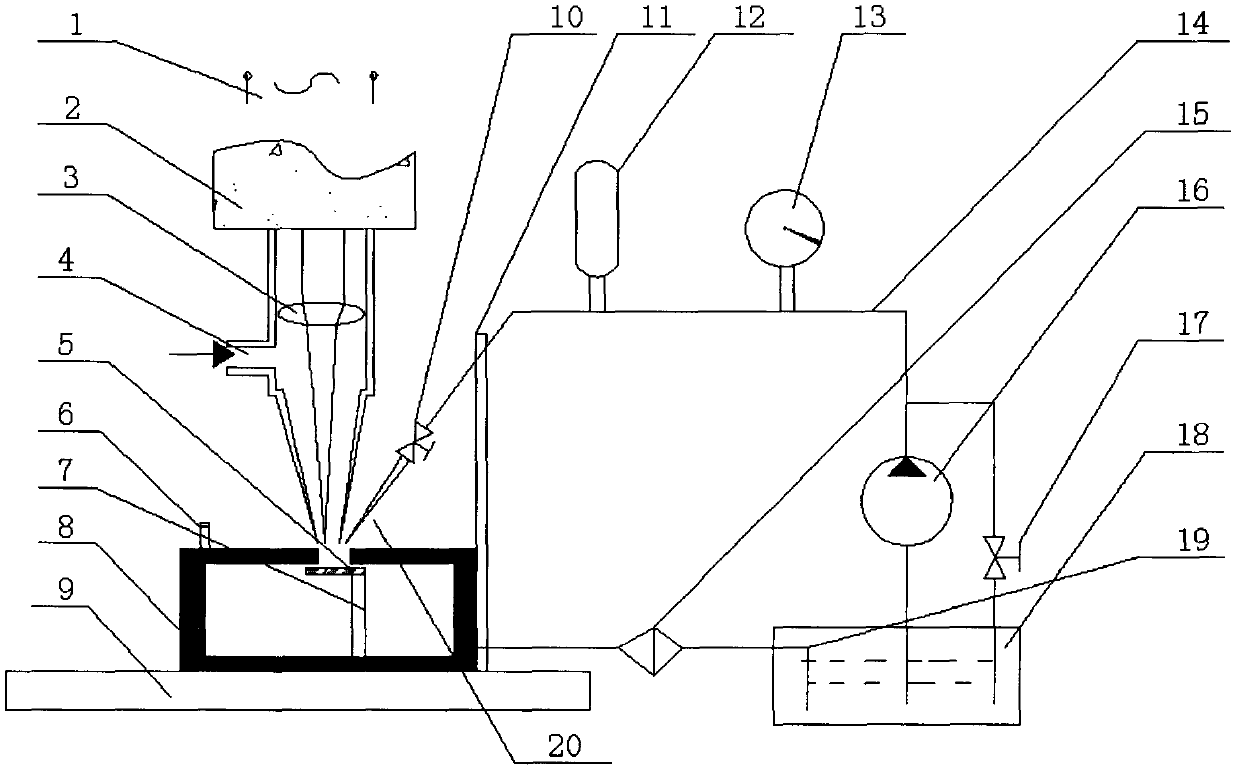

Laser induced low pressure jet flow combined etching processing method and device

InactiveCN103317234AEasy to cleanImprove surface finish qualityLaser beam welding apparatusHigh energy laser beamHigh pressure

The invention discloses laser induced low pressure jet flow combined etching processing method and device thereof. The method comprises the following steps: the operations of cutting, drilling and slotting are performed on a workpiece by utilizing high-energy laser beams generated by a laser processing system, and meanwhile erosion is performed on the material surface subjected to laser ablation through high-speed jet flow beams generated by a corrosive medium jet flow device, so that the purpose of removing the material is achieved; the device comprises a laser device and a power source, and further comprises a jet flow generation device and a corrosion liquid circulating reflux device, wherein the jet flow device comprises a corrosion liquid tank, a plunger piston high pressure pump, a pressure gauge, an accumulator, a one-way control valve, a corrosion-resistant spray nozzle and a jet flow device fixed fixture. The method disclosed by the invention has the advantages that the laser ablation is mainly performed, the cooling of high-speed corrosive medium jet flow beams, synchronous erosion and combined processing effect of the cooling and the erosion are added on the basis of the laser ablation, so that the laser induced low pressure jet flow combined etching processing of the material is realized; the invention provides an efficient, clean and combined etching processing process.

Owner:JIANGNAN UNIV

Method for laser-assisted polishing of CVD diamond

ActiveCN109590811AImprove polishing efficiencyImprove polishing qualityPolishing machinesMetal working apparatusLaser assistedGraphite

The invention relates to a method for laser-assisted polishing of a CVD diamond. The method comprises the following steps: first, selecting a suitable laser type according to the material property ofthe CVD diamond, and simulating the laser ablation of the CVD diamond so as to acquire suitable laser ablation parameters; then, carrying out laser rough polishing based on optimum laser process parameters; and finally, carrying out mechanical precision polishing by the adoption of a polishing disc till the required precision is achieved, so that a graphitization layer generated during the laser ablation process and surface defects such as microcracks can be removed. Through the method provided by the invention, the problems that the graphitization layer is easy to generate during the laser polishing process of the CVD diamond and the polishing efficiency of the mechanical polishing process is low can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

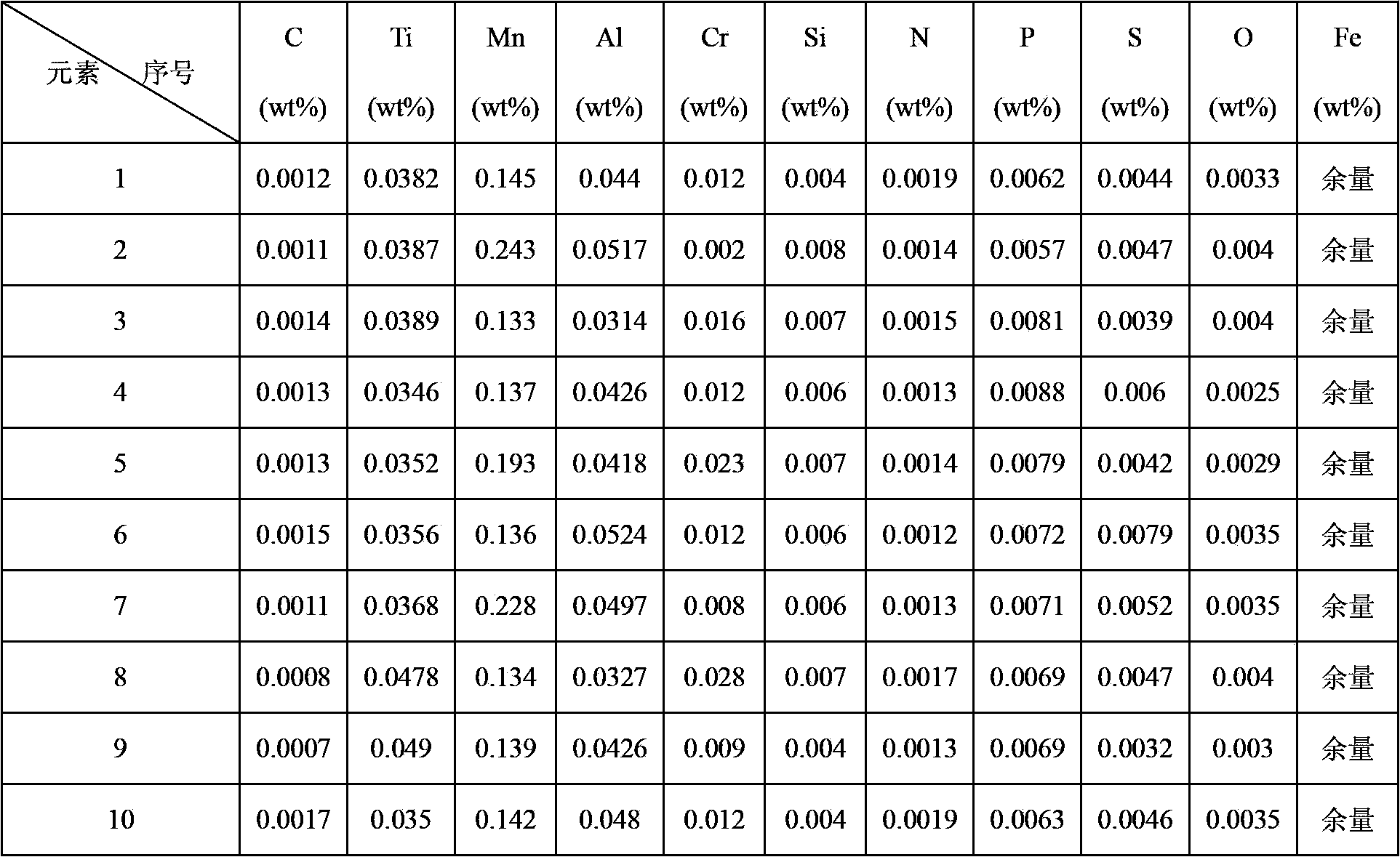

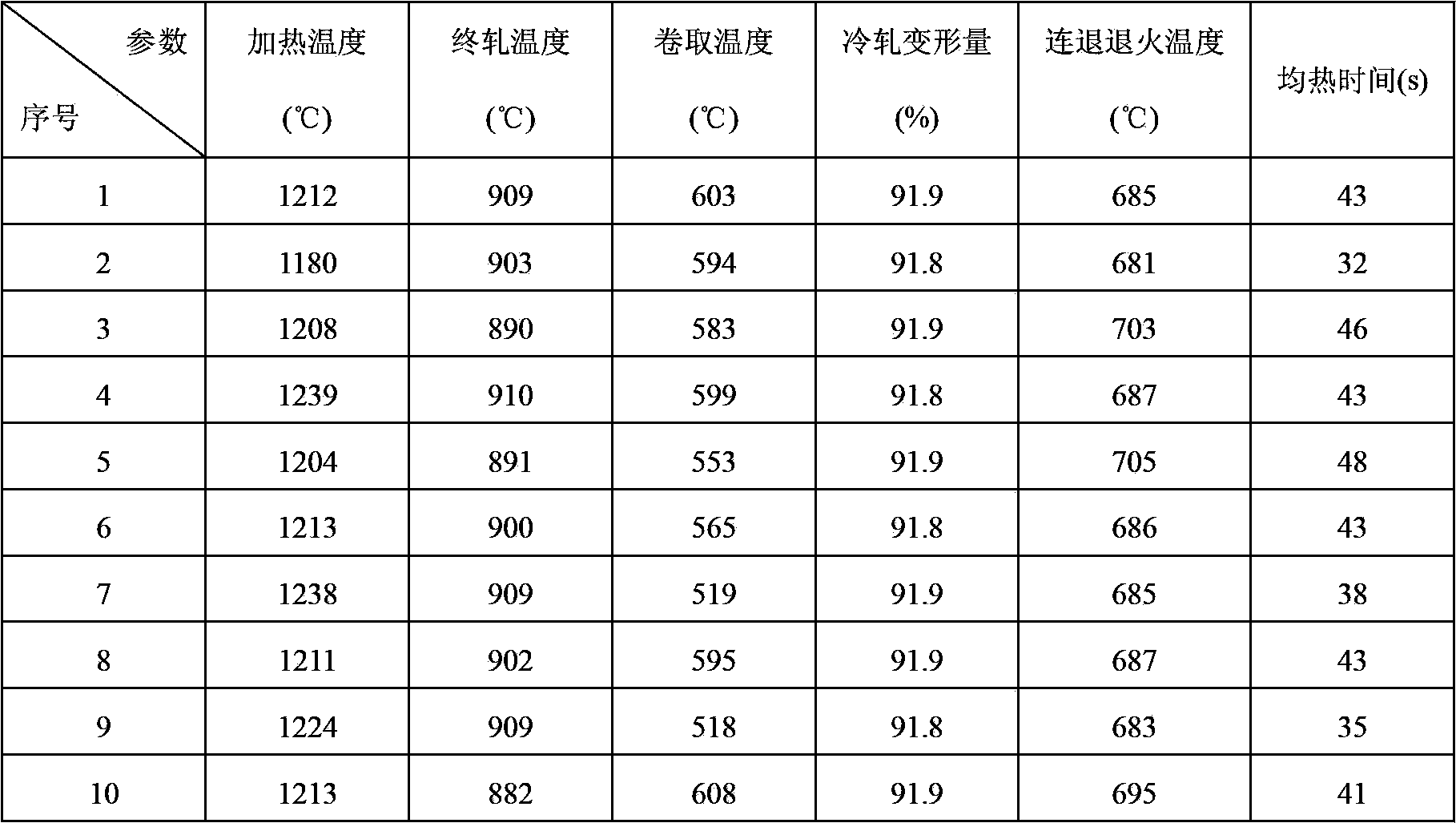

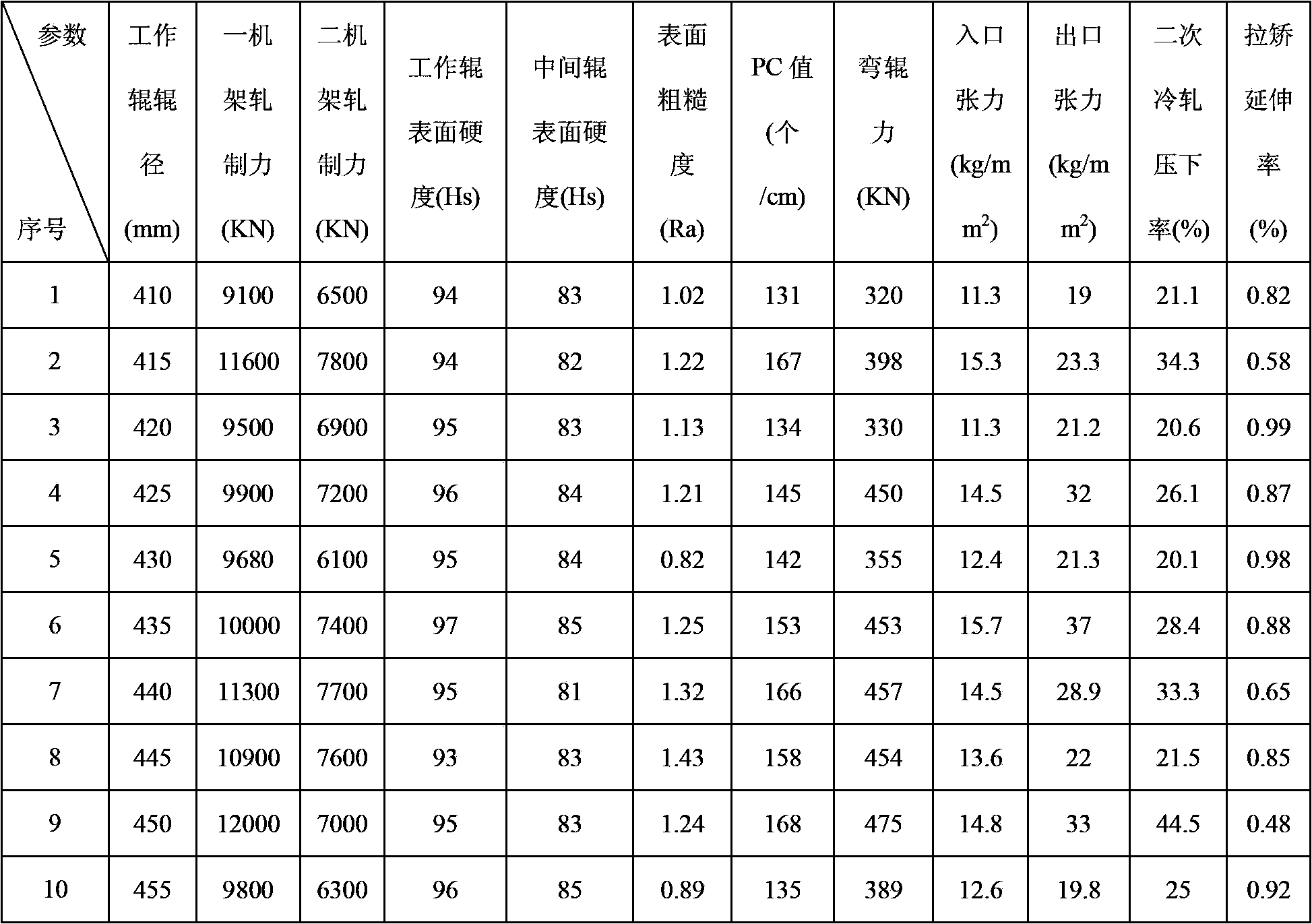

Manufacturing method of secondary-cold-rolling shadow mask strip steel in thin specification

The invention discloses a manufacturing method of secondary-cold-rolling shadow mask strip steel in a thin specification. The manufacturing method comprises the following steps of: carrying out converter steelmaking; carrying out continuous billet casting; carrying out acid washing and cold rolling; preparing a machine set; carrying out continuous annealing; carrying out secondary cold-rolling; degreasing; and finishing and oiling. The mass percentage of each element is controlled in a corresponding range, wherein the mass percentage of C element is controlled to be less than or equal to 0.002%; the plate temperature is 685-705 DEG C and the soaking time lasts for 30-50 seconds in a heating section and a soaking section of the continuous annealing step; and the rolling reduction of secondary cold rolling is 20%-50%. By using the manufacturing method, a shadow mask strip steel product having ultra-low carbon, an thickness of less than or equal to 0.15 mm and better surface quality and use property can be obtained; as a secondary cold rolling process is adopted, the strength and the rigidity of an annealed product can be improved, decarburization and annealing steps can be omitted, the production flow can be shortened, the production cost can be reduced and the energy consumption and the waste discharge can be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

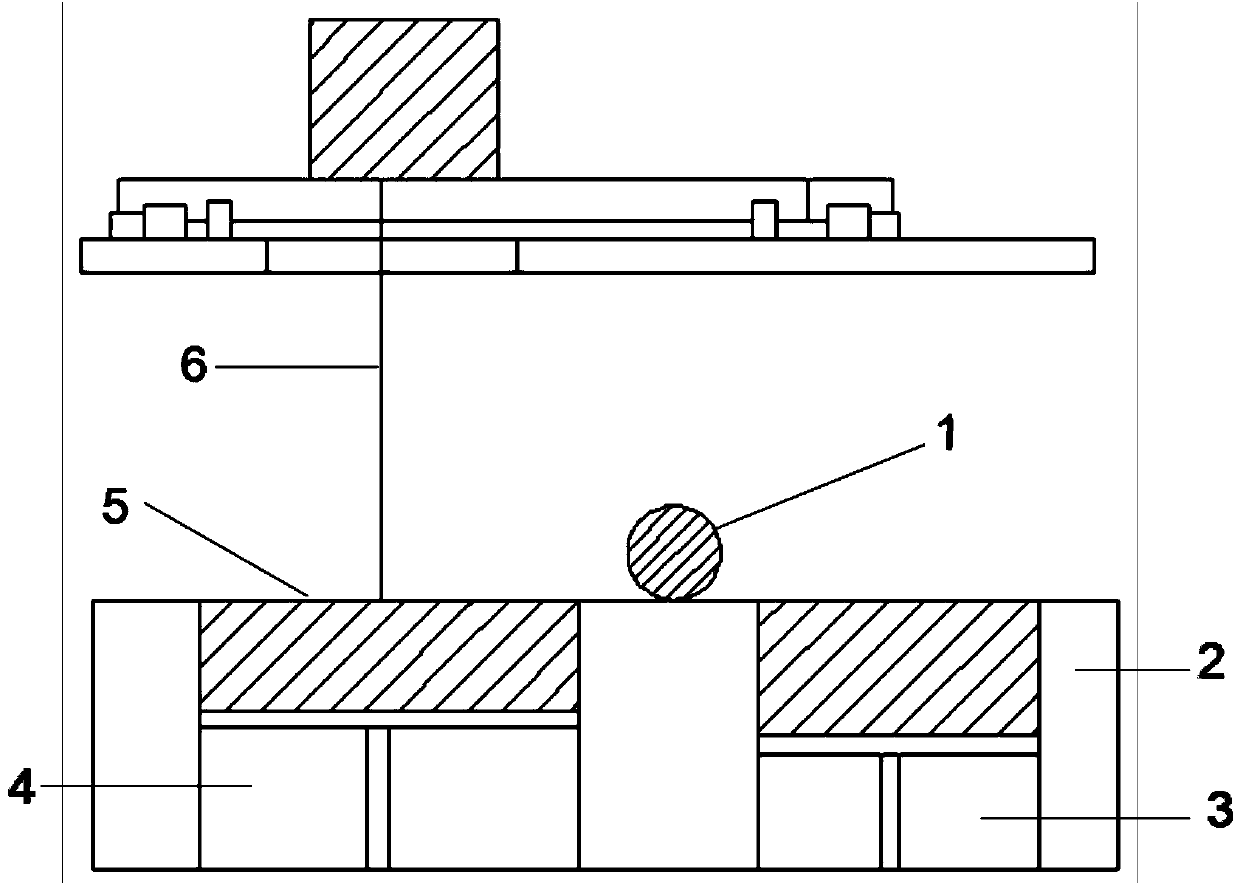

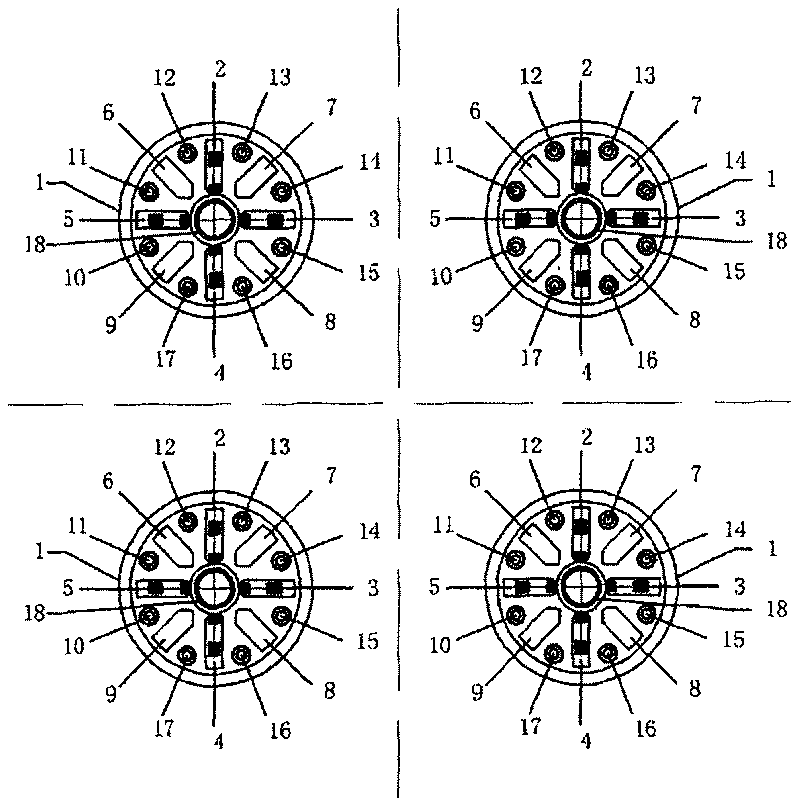

Resetting device using flexible positioning and rigid clamping in combination and positioning method thereof

ActiveCN101704200ASolve the problem of batch transfer at the same timeExtension of timePositioning apparatusMetal-working holdersCircular coneEngineering

The invention relates to a resetting device using flexible positioning and rigid clamping in combination and a positioning method thereof. The invention is characterized in that a cartridge comprises two to four radially-arranged positioning gears, the lateral side of each positioning gear is provided with a positioning slant surface, Z-direction stopping planes are arranged between two adjacent positioning gears, a workpiece supporting board is provided with positioning slots fit with the positioning gears and positioning planes fit with the Z-direction stopping planes, a pop-rivet comprises a pop-rivet body which is connected with the workpiece supporting board by bolts, the pop-rivet orifices on the cartridge is provided with positioning cone surfaces, the lateral side of the pop-rivet body is provided with cone-shaped positioning contact planes fit with the positioning cone surfaces. The device can simultaneously realize precise resetting and rigid clamping, and ensure high safety and reliability of mechanical processing and high manufacture preciseness and efficiency of the processed object.

Owner:上海麦迅机床工具技术有限公司

Abrasion-resistant steel good in surface quality and preparation method thereof

ActiveCN110499456AReduce alloy costLow susceptibility to weld cracksFurnace typesHeat treatment furnacesSteelmakingToughness

The invention relates to abrasion-resistant steel good in surface quality. The abrasion-resistant steel comprises the components of 0.12-0.20% of C, 0-0.1% of Si, 0.6-1.20% of Mn, 0.010-0.040% of Nb,0-0.01% of V, 0.010-0.030% of Ti, 0-0.04% of Al, 0-0.1% of Ni, 0-0.1% of Cu, 0.10-0.40% of Cr, 0-0.1% of Mo, 0.001-0.005% of B, 0.0010-0.0050% of Ca, 0-0.010% of P, 0-0.0015% of S, 0-0.0012% of O, 0-0.0035% of N, 0-0.0002% of H and the balance Fe; and the carbon equivalent CEV is smaller than or equal to 0.4, and PCM is smaller than or equal to 0.25. The production technological process comprisesthe steps of converter steelmaking, LF refining, VD or RH high vacuum degassing, continuous casting, heating, rolling, shot blasting treatment, quenching and tempering. The abrasion-resistant steel has the better surface quality and is free of gas pits, inclusion, pockmarks, press-in scales and other surface defects. The depth of surface mottles caused by scale disengagement is smaller than or equal to 0.1 mm, and steel plate surface coping can be not conducted. Based on element design, preheating-free welding and excellent toughness can be further achieved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

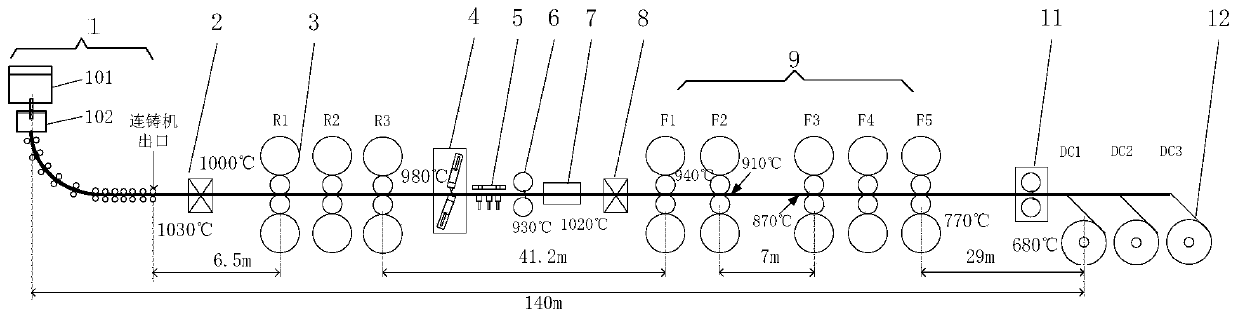

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

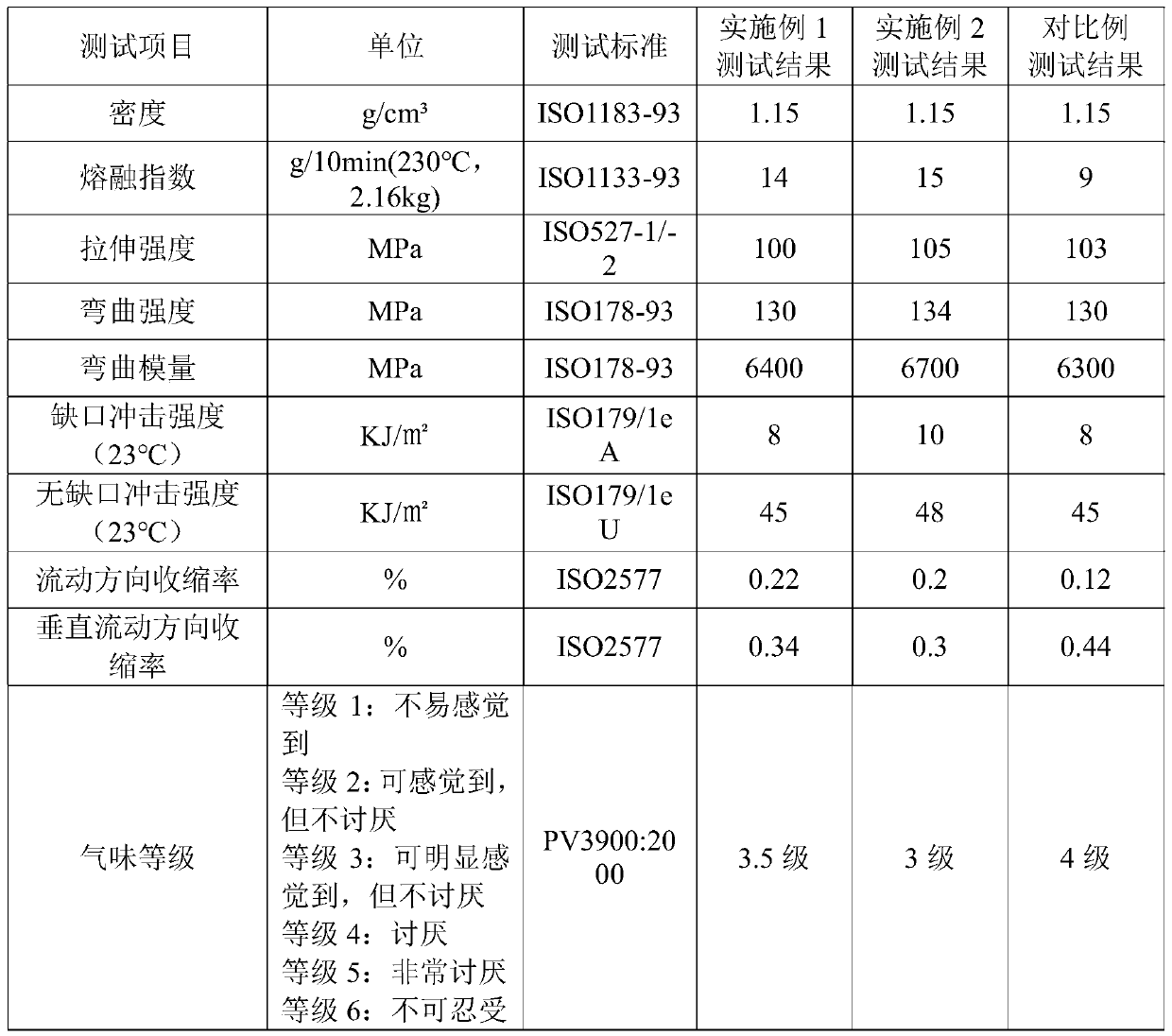

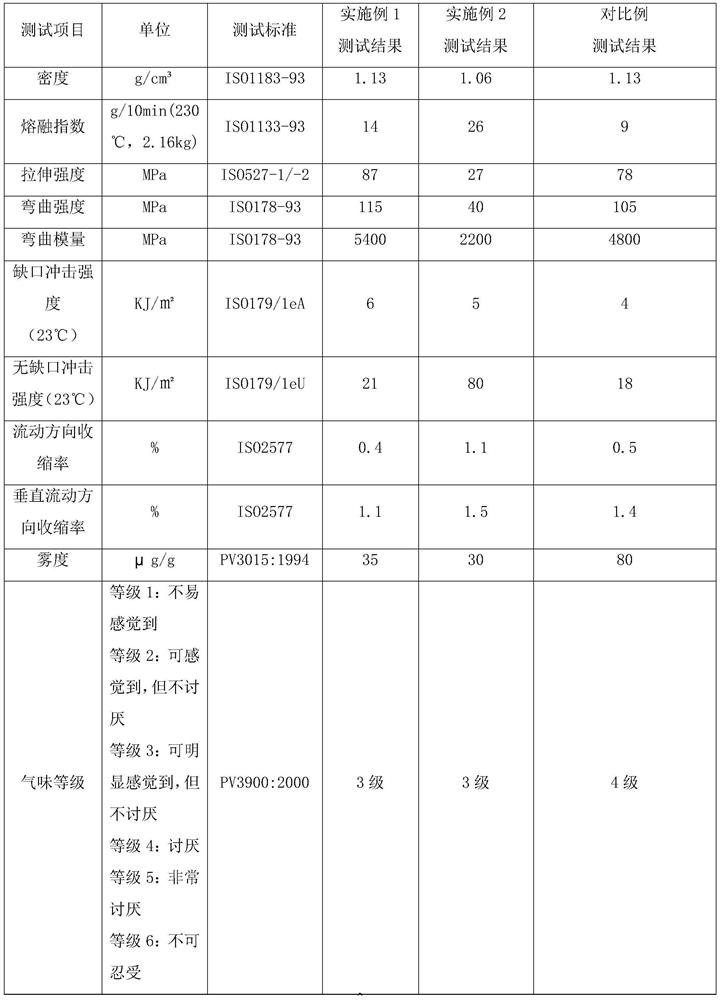

Low-odor low-VOC glass fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a low-odor low-VOC glass fiber reinforced polypropylene composite material and a preparation method thereof. The low-odor low-VOC glass fiber reinforced polypropylene composite material comprises the following raw materials in parts by weight: 50-90 parts of PP resin, 10-50 parts of chopped flat glass fibers, 0-1 parts of a lubricant, 0-4 parts of a compatilizer, 0-2 partsof an antioxidant and 0-2 parts of black masterbatch. The low-odor and low-VOC chopped flat glass fibers are used for replacing common cylindrical glass fibers, the smell and the VOC content of the glass fiber reinforced polypropylene composite material are reduced, the process stability of double-screw extrusion high-glass-fiber-content drawing and dicing can be improved, the fluidity, the mechanical property and the workpiece appearance of the glass fiber reinforced polypropylene composite material are improved, and buckling deformation of a glass fiber reinforced polypropylene composite material product is reduced. Meanwhile, low-odor and high-activity maleic anhydride grafted PP is used as a compatilizer, extremely high compatibilization efficiency and high reaction active groups of the compatilizer are fully utilized, and the odor and VOC of the glass fiber reinforced PP composite material are further reduced on the premise that the performance is guaranteed.

Owner:CHONGQING POLYCOMP INT

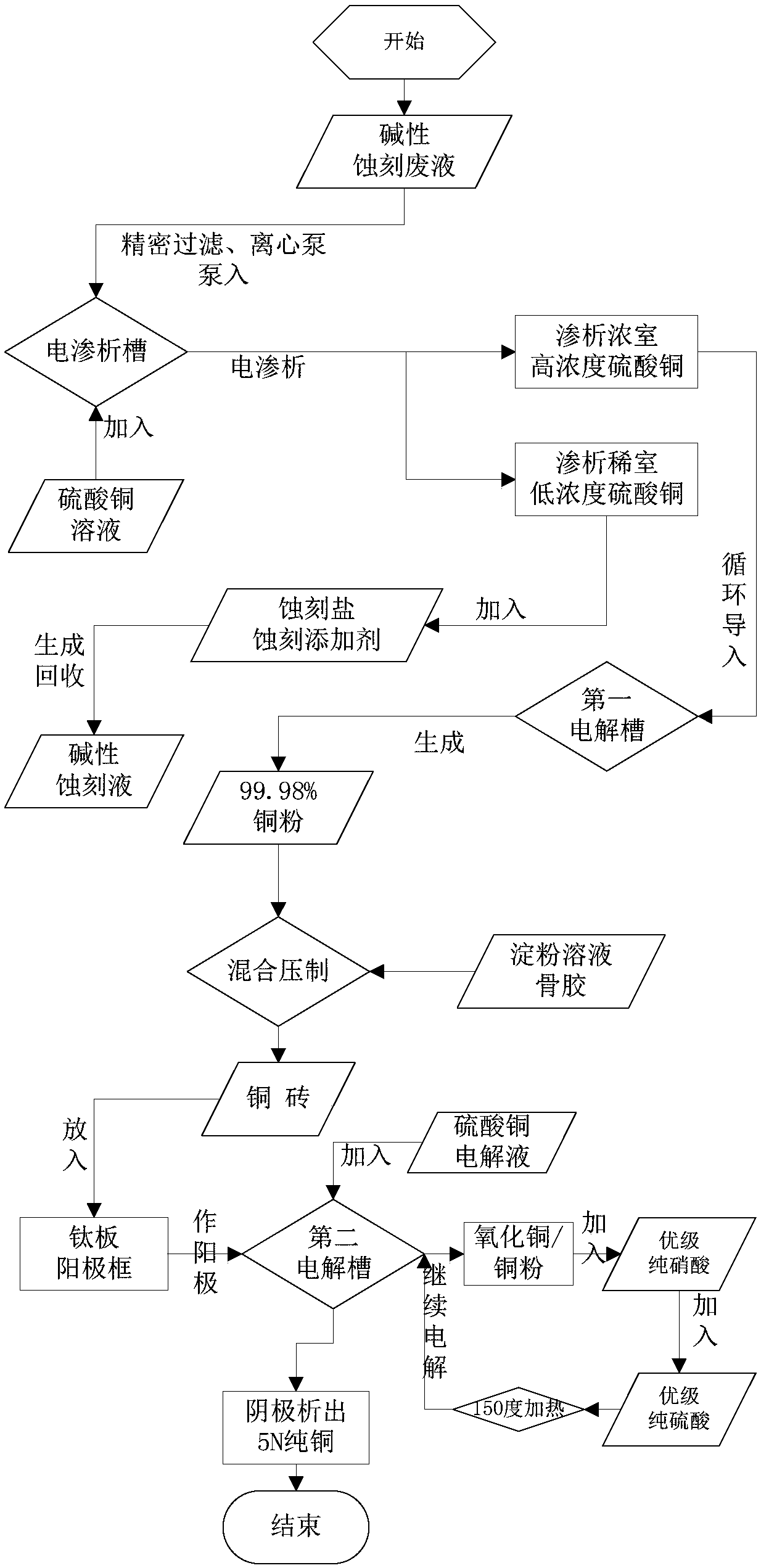

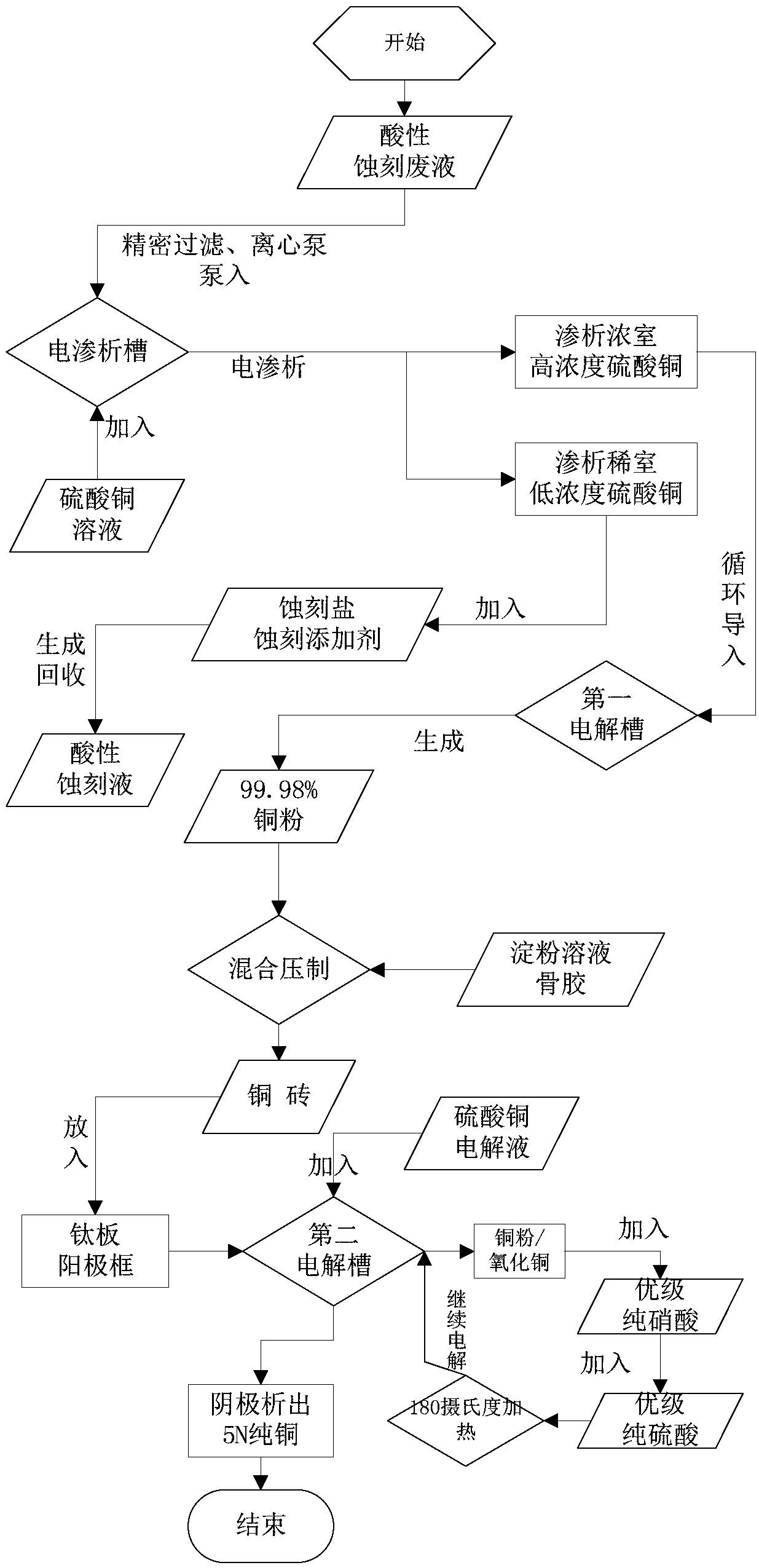

Method for recovering 99.98% copper powder from etching liquid and preparing 99.999% cathode copper

ActiveCN109252190AImprove surface qualityImprove general performancePhotography auxillary processesProcess efficiency improvementHigh concentrationBrick

The invention discloses a method for recovering 99.98% copper powder from etching liquid and further processing the copper power to prepare 99.999% cathode copper. According to the method, firstly, the etching liquid is subjected to dialysis in an electrodialysis cell containing a copper sulphate solution, and copper ions in the etching liquid enter the copper sulphate solution, so that a high-concentration copper sulphate solution is obtained; then the high-concentration copper sulphate solution is introduced into an electrolytic cell for electrolysis, so that the high-purity copper powder isobtained; then the high-purity copper powder is pressed into a brick, the copper brick is placed in a conductive frame made from a titanium material, and is used as an anode, a pure titanium board isadopted as a cathode, and refining is conducted in the electrolytic cell so that the cathode copper with purity of 99.999% can be obtained at the cathode of the electrolytic cell. The method belongsto the field of ageing etching liquid for copper extraction, regeneration and reuse, and compared with a traditional technology, the method has the characters that added values of products are high, both the copper powder and the cathode copper can be used as products, moreover, a process is short, equipment is little, and energy consumption is low; moreover, in the whole process, no other agentsare introduced, no intermittent products are polluting, and the requirements of environmental-protection can be met.

Owner:GUANGZHOU JICHI ENVIRONMENTAL TECH CO LTD

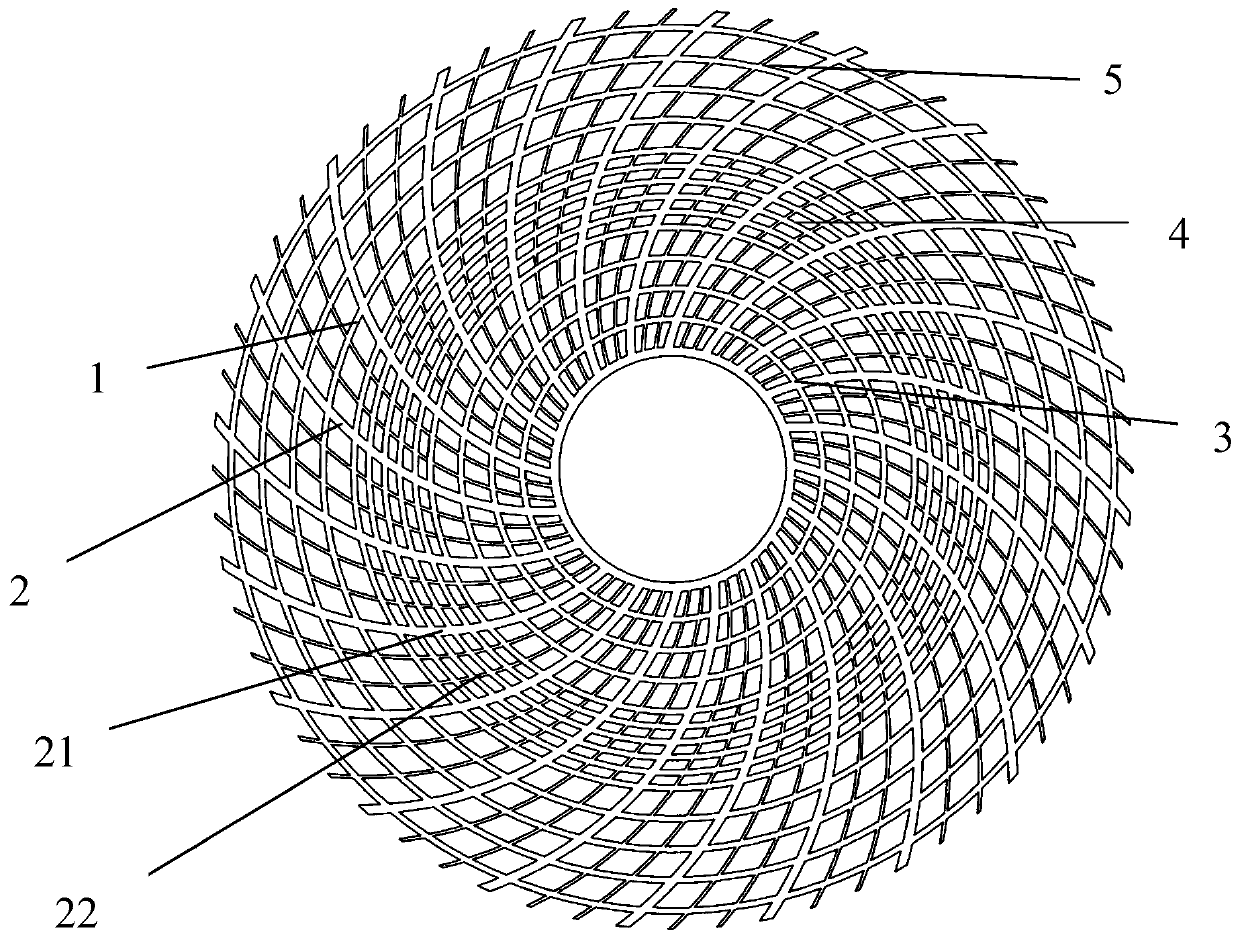

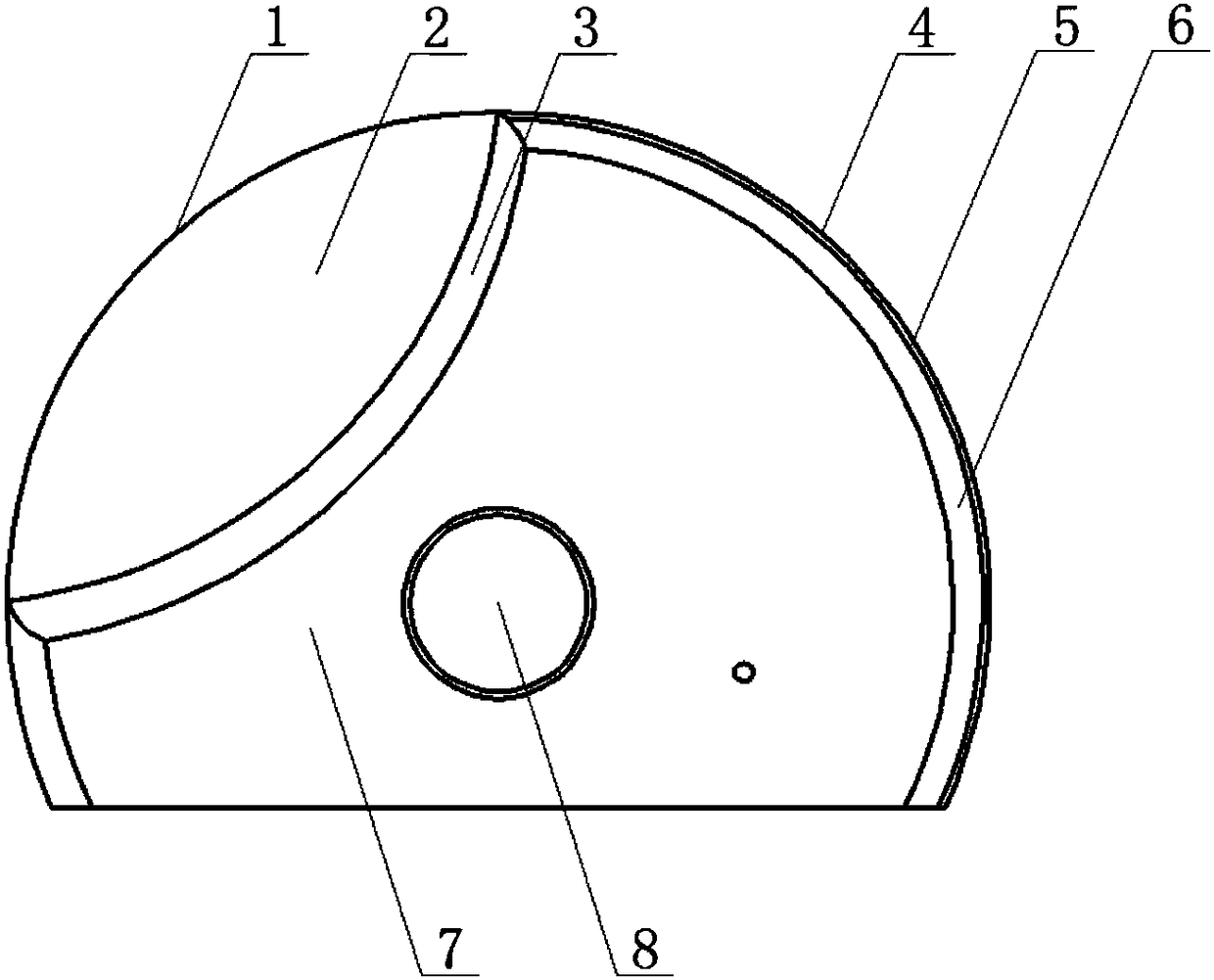

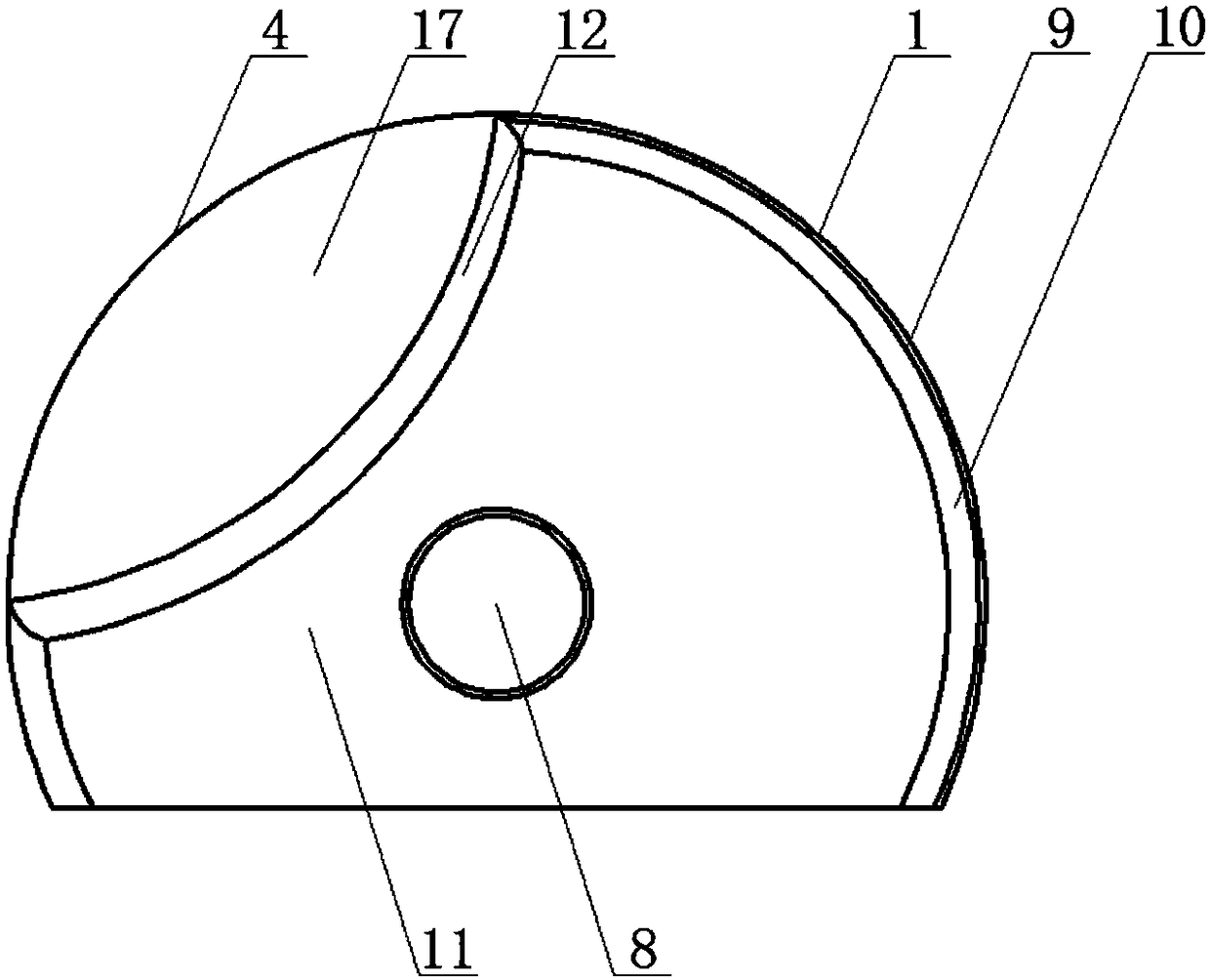

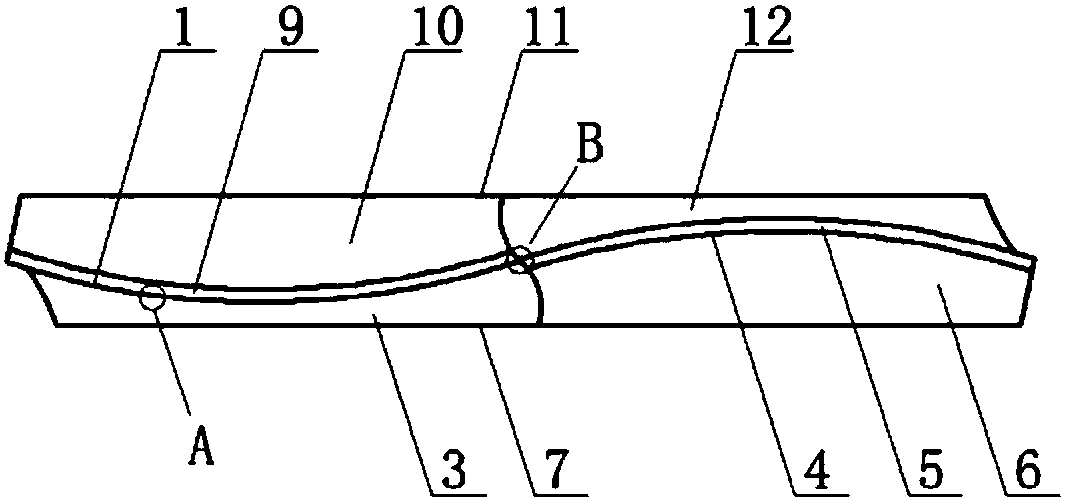

Groove grinding disc and method for manufacturing groove grinding disc

PendingCN110948381AReduce resistanceGood for chip evacuationGrinding devicesLapping toolsGrindingEngineering

The invention provides a groove grinding disc and a method for manufacturing the groove grinding disc. The grinding disc is provided with a groove; the groove is formed by coupling a plurality of concentric grooves with radii gradually increasing and a plurality of spiral line grooves which are arranged at equal intervals; the centers of the spiral line grooves are concentric with the centers of the concentric grooves; the grinding disc is divided into a first area, a second area and a third area from inside to outside in the radial direction; and the distance between the concentric grooves ofthe first area and the distance between the concentric grooves of the third area are greater than the distance between the concentric grooves of the second area. The application of the technical scheme can realize the improvement of the flow performance of grinding liquid in the grinding and polishing process, and the problems of blockage and wear of the grinding disc are obviously improved.

Owner:HUAQIAO UNIVERSITY

Pretreatment-free directly formed hot rolled low carbon steel and manufacturing method thereof

InactiveCN102676915AEmission reductionEasy to produceTemperature control deviceMetal rolling arrangementsChemical compositionAcid washing

The invention discloses pretreatment-free directly formed hot rolled low carbon steel, which is characterized by comprising the following chemical compositions in percentage by weight: 0.01 to 0.08 percent of C, 0.01 to 0.05 percent of Si, 0.01 to 0.50 percent of Mn, less than or equal to 0.010 percent of S, less than or equal to 0.015 percent of P and the balance of iron and inevitable impurities; and moreover, the scale on the surface of the steel mainly comprises 80 to 95 percent of Fe3O4. According to the method, by optimizing a plate blank heating and rolling process and controlling cooling water quality, the production cost is low. By the pretreatment-free directly formed hot rolled low carbon steel, the original acid-washing pretreatment can be eliminated, the phosphating and painting are not affected after the steel plate is punched and formed, the emission of waste acid is reduced, production procedures are simplified, the production cost is reduced, energy consumption is reduced, the environment is protected, the economic benefit of an enterprises is improved and the competitiveness of the enterprise is improved.

Owner:武钢集团有限公司

Shell preparation method for investment casting

ActiveCN108746496AEffective identification of stress concentration locationsEffectively identify the easy-to-deform position of the investment patternFoundry mouldsFoundry coresInvestment castingMold filling

The invention relates to a shell preparation method for investment casting. The shell preparation method comprises the steps of stiffener determining, reinforced investment pattern module preparation,shell preparation, stiffener removal, investment pattern removal and shell roasting. According to a casting piece structure, the investment pattern stress situation and mold filling solidification process computer simulation, the position of a stiffener is determined, and the investment pattern and the shell are prevented from deformation advantageously and are supported. By removing the stiffener, a hole channel and a demolding opening are formed in the investment pattern, the shell can be separated from the investment pattern without being turned over, and the surface quality of an inner cavity of the shell is improved.

Owner:BAIMTEC MATERIAL CO LTD

High-toughness low-shrink polyamide material and preparation method thereof

The invention discloses a high-toughness low-shrink polyamide material and a preparation method thereof. The high-toughness low-shrink polyamide material is prepared from the following components in percentage by weight: 50-68% of polyhexamethylene adipamide resin, 20-30% of mica powder, 10-20% of toughener, 0.3-0.6% of lubricant, 0.3-0.6% of antioxidant and 1-2% of dispersant. The invention combines the enhancement and toughening technologies, regulates the overall performance of the product based on material selection, achieves an overall balance among strength, heat resistance and low-temperature characteristics, and ensures that the material has favorable mechanical properties at both low temperature and normal temperature and the strength and the toughness are relatively complemented. Besides, the high-toughness low-shrink polyamide material has the advantages of small shrinkage, high surface quality and low material cost, thereby being an economical, practical and durable modified composite material.

Owner:SHENZHEN KEJU NEW MATERIAL

Low-odor low-VOC and low-haze glass fiber reinforced polypropylene composite material and preparation method thereof

The invention provides a low-haze low-odor low-VOC glass fiber and mineral raw material hybrid reinforced polypropylene composite material and a preparation method thereof, low-odor low-VOC chopped flat high-strength high-modulus glass fibers are used for replacing common cylindrical glass fibers, so that the odor, the VOC content and the haze of the polypropylene composite material are reduced, the flowability, the mechanical property and the workpiece appearance of the polypropylene composite material can also be improved, and the buckling deformation of a polypropylene composite material product is reduced. Meanwhile, low-odor high-activity maleic anhydride grafted PP is used as a compatilizer, so that the odor, VOC and haze of the glass fiber and mineral raw material hybrid reinforcedPP composite material are further reduced. Meanwhile, high-purity and low-volatility polypropylene wax is used as a lubricant, so that the haze is further reduced on the premise of ensuring the flowability of the glass fibers and talcum powder in the PP resin. Meanwhile, a microporous polymer adsorbent HL-4200 with a very good adsorption effect is adopted to further adsorb volatile small molecularsubstances, and a double-vacuum process is adopted, so that the odor and haze are further reduced.

Owner:CHONGQING POLYCOMP INT

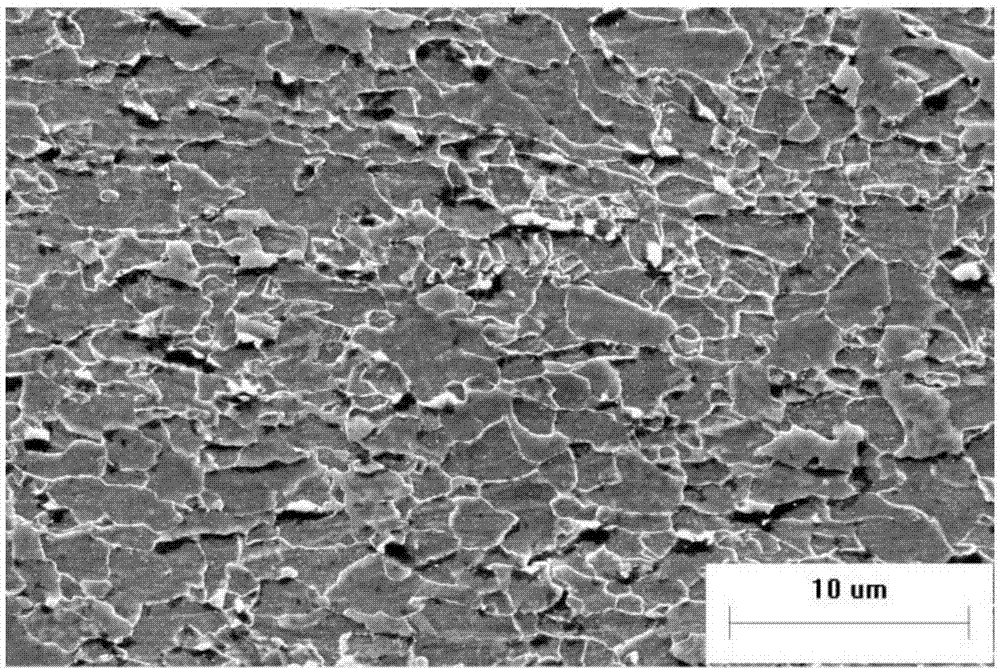

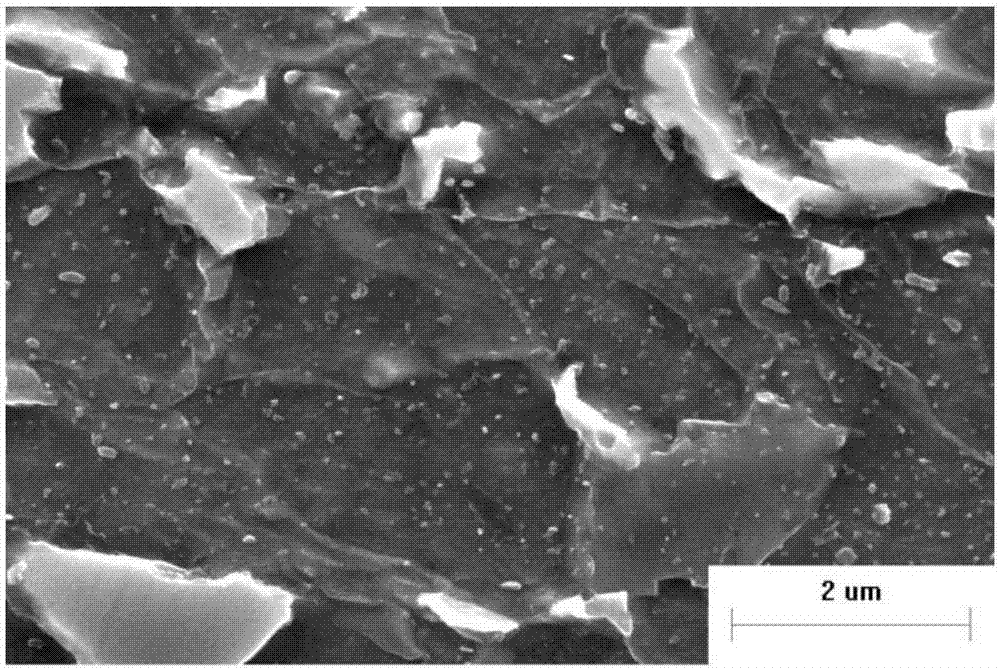

780 MPa-grade hot-rolled dual-phase steel with excellent hole expanding performance and preparation method of 780 MPa-grade hot-rolled dual-phase steel

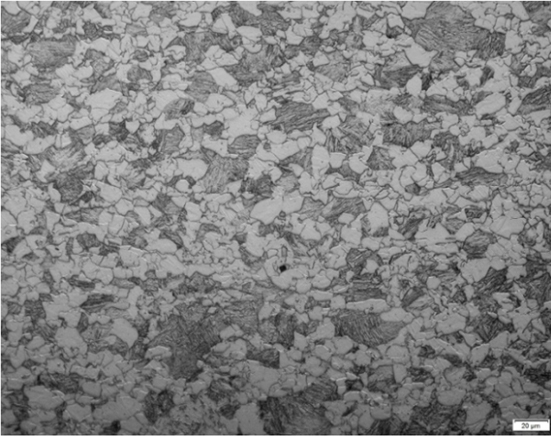

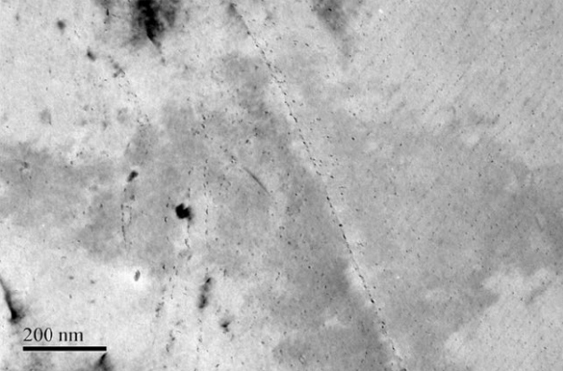

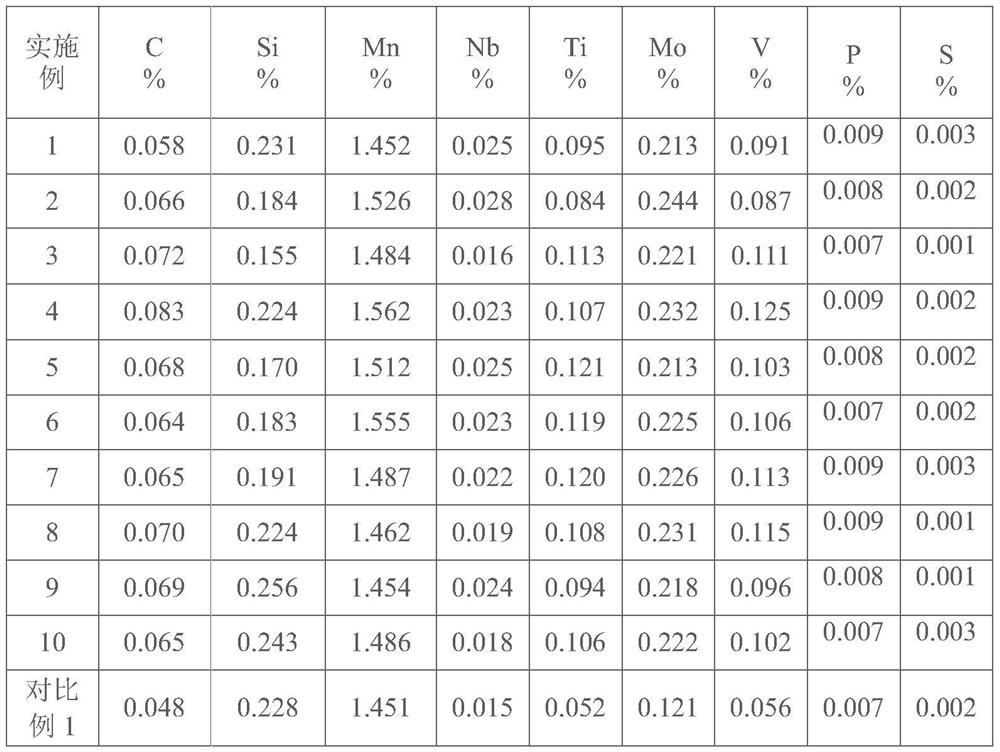

InactiveCN113005367AEffect on mechanical propertiesAvoid Surface Quality IssuesTemperature control deviceFurnace typesFerritic matrixContinuous casting

The invention relates to 780 MPa-grade hot-rolled dual-phase steel with excellent hole expanding performance. The 780 MPa-grade hot-rolled dual-phase steel comprises the following chemical components including, by weight: 0.05%-0.09% of C, 0.10%-0.30% of Si, 1.40%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.08%-0.12% of Ti, 0.20%-0.24% of Mo, 0.010%-0.030% of Nb and 0.08%-0.12% of V. The production method comprises the following steps of carrying out vacuum treatment after converter smelting, heating a casting blank after continuous casting is conducted to form a blank, carrying out rough rolling, carrying out finish rolling, carrying out two-stage cooling and carrying out coiling. The grain size grade of ferrite and martensite is greater than or equal to 10 grades; the area ratio of the martensite is 30%-50%, a ferrite matrix contains a large number of nanoscale cluster precipitates, the size of the nanoscale cluster precipitates is 1-8 nm, and the density of the nanoscale cluster precipitates can reach 1*10<3> / microns<2>; and the tensile strength of a hot-rolled steel plate is larger than or equal to 780 MPa, the ductility is larger than or equal to 15%, the yield ratio is smaller than or equal to 0.75, the hole expanding performance is larger than or equal to 55%, and the use requirements for high strength, high plasticity and excellent hole expanding performance of automobile steel can be completely met.

Owner:武汉钢铁有限公司

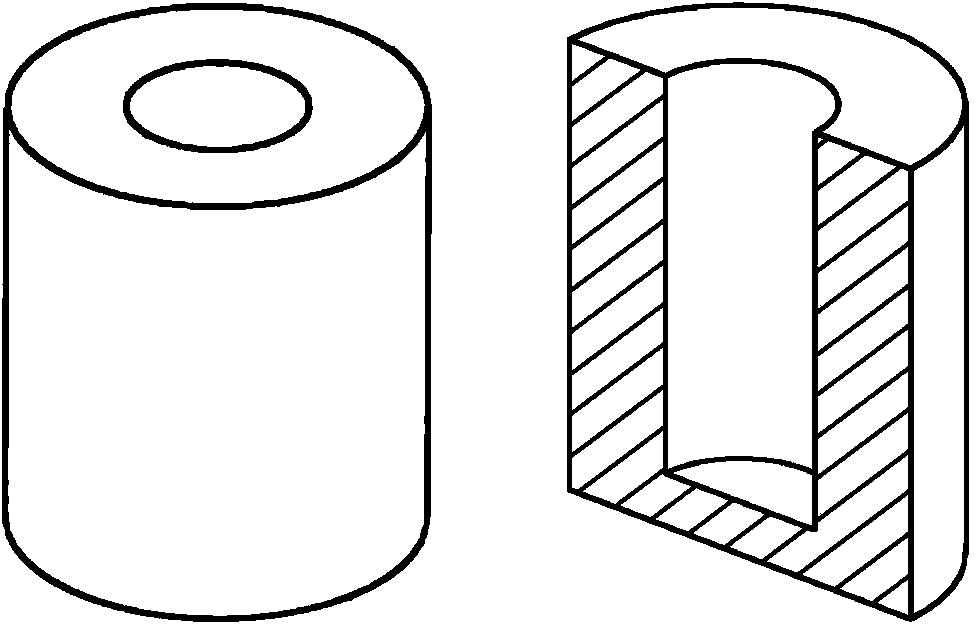

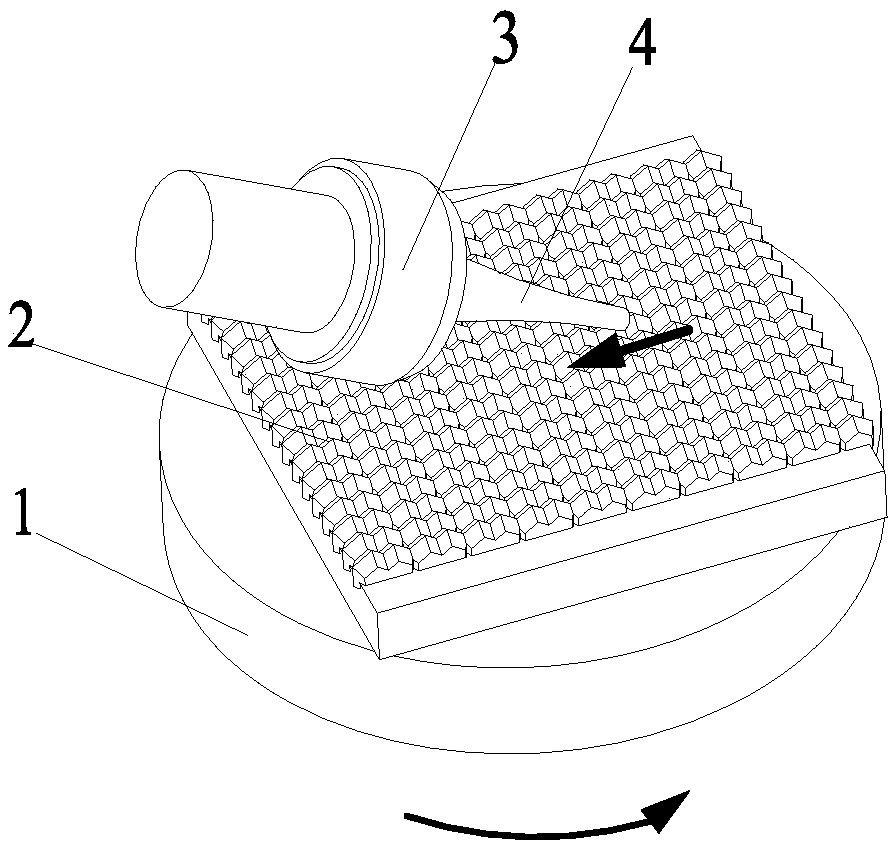

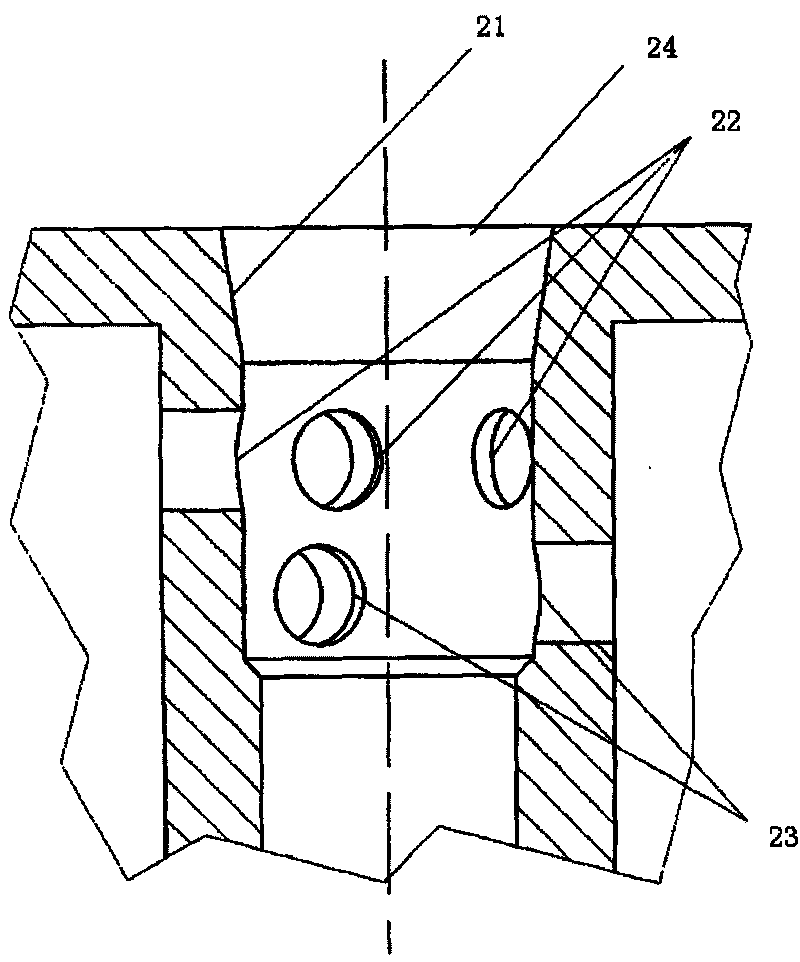

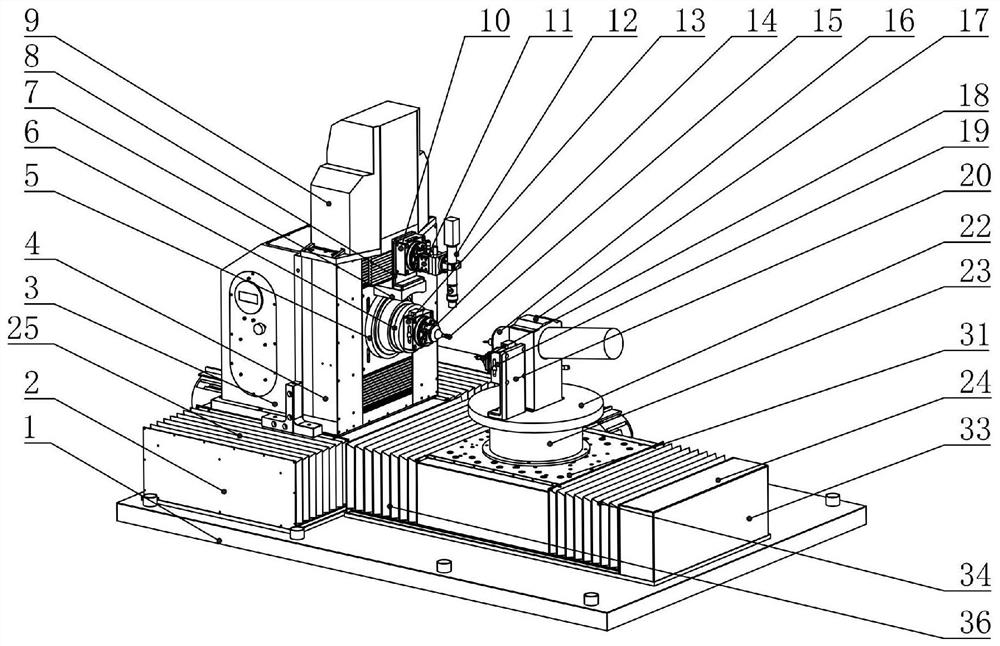

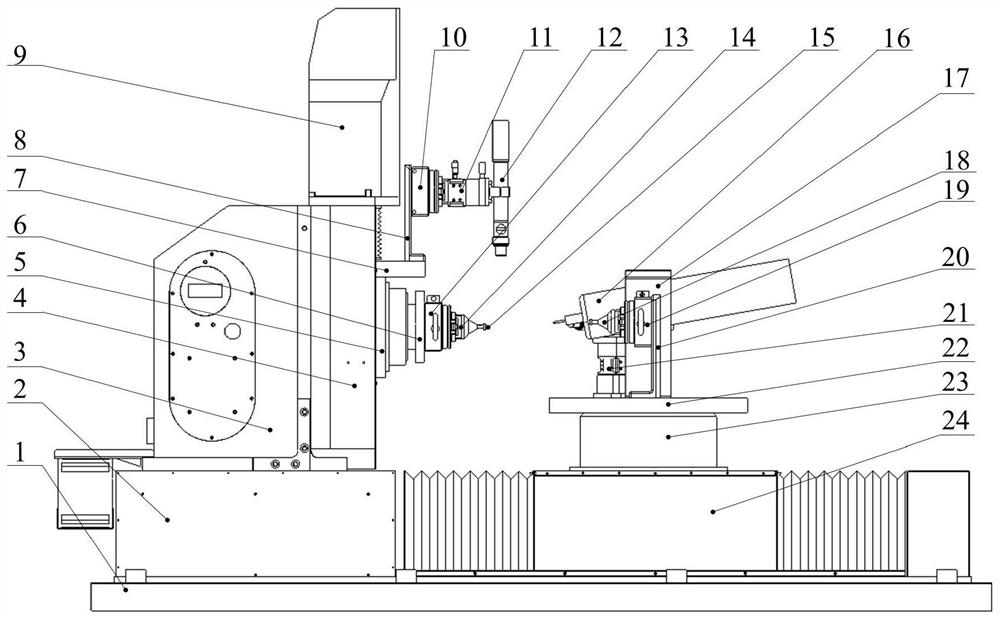

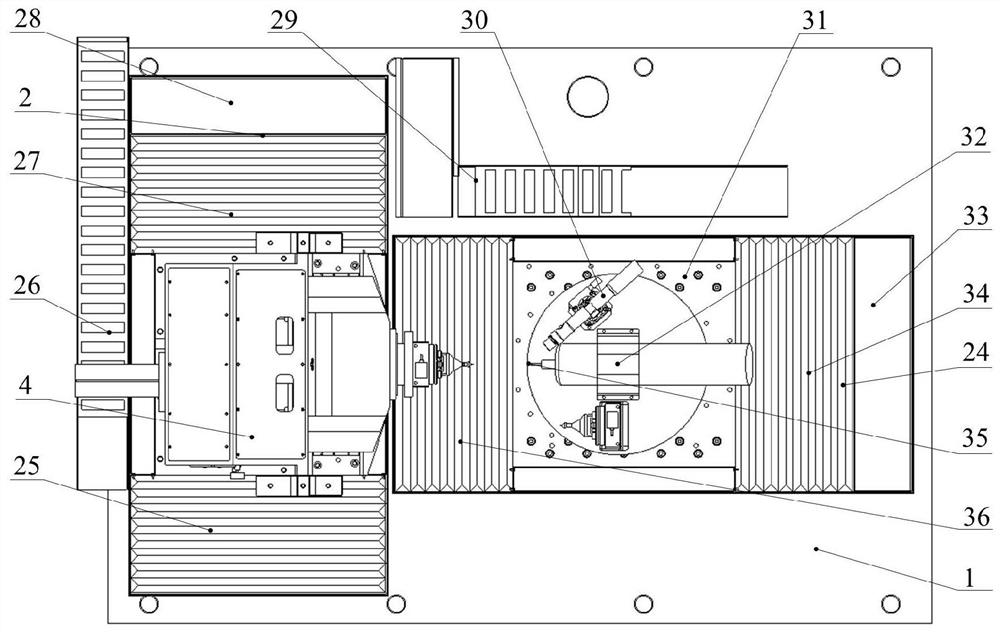

Machining device for full-surface micro-pit structure of thin-wall spherical shell type micro-component

ActiveCN113695646AAchieve high precision machiningExcellent contour errorWork clamping meansMeasurement/indication equipmentsImage resolutionMonitoring system

The invention discloses a machining device for a full-surface micro-pit structure of a thin-wall spherical shell type micro-component, and relates to the technical field of micro-component surface machining devices. The problems that under the constraint of the micro-space scale, the thin-wall spherical shell type micro-component has special structural characteristics, is non-uniform in material, asymmetric in surface and has tiny surface defects, and fluid mechanics is not stable in the machining process are solved. According to the machining device, a base is made of granite materials, and therefore vibration can be well absorbed; a high-precision linear unit and a high-precision rotating unit are adopted as main moving parts of the device, and a workpiece clamping system, a high-resolution CCD monitoring system, a zero point positioning system and a turning secondary clamping quick-change system are installed on the base in a centralized mode; the structural design is compact, and the technical problems of clamping, turning, tool setting, capturing and recognizing of the micro-pit structure and the like of the thin-wall spherical shell type micro-component can be effectively solved; and an air static pressure workpiece shaft is adopted for rotational motion of a workpiece, a milling shaft is obliquely arranged, and therefore the high machining speed and the high machining precision can be achieved.

Owner:HARBIN INST OF TECH

Finishing withdrawing-straightening tension control method for deep-draw galvanized steel sheet

ActiveCN103934282AImprove surface qualityGuaranteed surface qualityTension/compression control deviceSheet steelEconomic benefits

The invention belongs to the technical field of galvanized steel sheet production methods, and relates to a finishing withdrawing-straightening tension control method for a deep-draw galvanized steel sheet for guaranteeing the steel sheet performance and the surface quality. According to the technical scheme, the tension set values before and after the finishing withdrawing-straightening are adjusted, and the matching relation between steel plates with different thicknesses and the tension before and after the finishing withdrawing-straightening is adopted, wherein the tension before finishing conforms to the formula: T(strip steel thickness)*(25-30)KN, and the tension after finishing and withdrawing-straightening conforms to the formula: T(strip steel thickness)*(27.5-33)KN. According to the finishing withdrawing-straightening tension control method, the surface quality of the deep-draw galvanized product can be guaranteed, the performance is not greatly affected, the requirement for machining and using performance of a user is met, and the performance aggravating effect brought by increasing the finishing rolling force to guarantee the surface of the deep-draw galvanized product is avoided. The performance judgment amending ratio of the deep-draw galvanized product is greatly reduced, the surface quality and the profit space of the deep-draw galvanized product are greatly improved, the competitiveness of enterprises is enhanced, and considerable economic benefits are brought to the enterprises.

Owner:HEBEI IRON AND STEEL

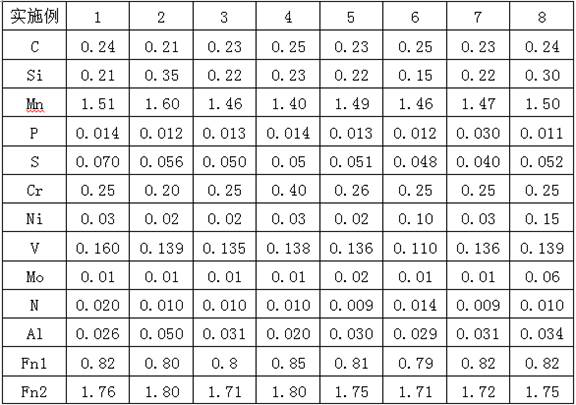

High-strength high-toughness non-quenched and tempered front axle steel and production method thereof

ActiveCN112143970AGood strengthGood low temperature toughnessProcess efficiency improvementImpact toughnessMaterials science

The invention discloses high-strength high-toughness non-quenched and tempered front axle steel and a production method thereof. The high-strength high-toughness non-quenched and tempered front axle steel comprises the chemical components of, by mass, 0.21%-0.25% of C, 0.15%-0.35% of Si, 1.40%-1.60% of Mn, 0.20%-0.40% of Cr, 0.009%-0.020% of N, 0.020%-0.050% of Al, 0.040%-0.070% of S, less than orequal to 0.030% of P, less than or equal to 0.15% of Ni, 0.11%-0.16% of V, less than or equal to 0.06% of Mo, and the balance Fe and inevitable impurities, wherein Fn1 is equal to 0.79-0.85%, and Fn2is less than or equal to 1.80%. The steel has an excellent strength and low-temperature toughness, is low in production cost, and is suitable for being used on heavy-duty automobiles. Molten steel obtained through the method is good in liquidity, and a single tundish continuous drawing molten steel amount reaches 600 tons; a liquid level fluctuation of a crystallizer is within + / -3 mm, and the surface of a continuous casting billet is good; a yield strength of a front axle of an obtained product is 590-650 Mpa, a tensile strength is 850-916 Mpa, a percentage elongation after fracture is 19%-23%, a percentage reduction of area is 55%-58%, the normal-temperature impact toughness is 70-90 J / cm < 2 >, and the low-temperature (minus 50 DEG C) impact toughness is 27-45 J / cm < 2 >; and an average value of fatigue life tests of a front axle assembly reaches 1,300,000 times.

Owner:SHIJIAZHUANG IRON & STEEL

A method for reducing the residual stress of steel rail and the obtained steel rail and its application

ActiveCN106086370BReduce residual stressImprove straightnessRailsFurnace typesSlow coolingCooling temperature

The invention relates to the field of steel making, in particular to a method for reducing the residual stress of a steel rail, the steel rail obtained according to the method, and the application of the steel rail. The method for reducing the residual stress of the steel rail comprises the step of sequentially carrying out accelerated cooling, slow cooling and air cooling on the rail head tread centers, the two sides of each rail head and the center part of the rail base of the steel rail obtained after rolling, wherein the starting cooling temperature of accelerated cooling is 650 DEG C to 950 DEG C, the cooling rate of accelerated cooling is 2 DEG C per second to 8 DEG C per second, the finish cooling temperature of accelerated cooling is 400 DEG C to 600 DEG C, the cooling rate of slowing cooling is 0.1 DEG C per second to 1.5 DEG C per second, and the finish cooling temperature of slow cooling is 180 DEG C to 300 DEG C. With the method for reducing the residual stress of the steel rail, on the premise that the tensile property of the steel rail is guaranteed, the residual stress of the steel rail can be effectively reduced, and the flatness of the steel rail can be improved. The steel rail is particularly suitable for high-speed railways.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

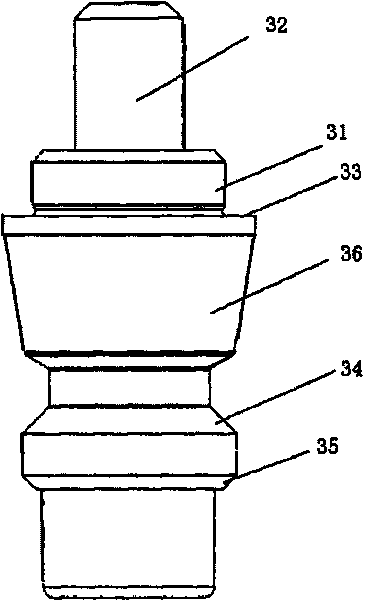

Preparation method of molded line used for stranded conductor

InactiveCN101834035AImprove surface qualityAvoid Surface Quality IssuesCable/conductor manufactureProduction rateElectrical conductor

The invention relates to the improvement of the preparation method of the molded line used for a transmission stranded conductor, and is characterized by comprising the following steps: firstly reducing deformation by multiple round broaching; carrying out normal temperature roll to form a molded line with a needed shape when approximating to the area of the needed molded line; and finally carrying out one molded line mold reforming. The invention realizes the optimal process combination of preparing molded line conductor in batch, the wire breaking frequency is greatly reduced, fundamentally no broken wire exists in the experiment, the production rate is high, and the efficiency is high, the production efficiency can be increased by at least more than 20%. In the same way, when aluminum ladder-shaped or Z-shaped molded lines are prepared, the production rates can respectively reach 11 m / s and 9-10 m / s; the prepared molded line has good surface quality, no burr, bright and clean large-length surface and no defects of hemmed edge, crackle, rag, delamination and the like, not only can save equipment investment, but also can save preparation energy consumption.

Owner:FAR EAST COMPOSITE TECH

Ball-end mill for milling curved surface splicing molds

InactiveCN108480731AImprove surface finish qualityReduce milling forceMilling cuttersMilling cutterEngineering

The invention provides a ball-end mill for milling curved surface splicing molds, relates to a ball-end mill, and solves the problems that by an existing blade type ball-end mill, the surface qualityof a machined workpiece is poor, and the machining cost is high. Two cutting blades are machined on the ball-end mill, one side of the first cutting blade is connected with a first front knife face, the first front knife face is lower than the upper surface of the ball-end mill and is parallel to the upper surface of the ball-end mill, the first front knife face is in transitional connection withthe upper surface of the ball-end mill through a first groove surface, and the other side of the first cutting blade is connected with a first rear knife face; and one side of the second cutting bladeis connected with a second front knife face, the second front knife face is lower than the lower surface of the ball-end mill and is parallel to the lower surface of the ball-end mill, the second front knife face is in transitional connection with the lower surface of the ball-end mill through a second groove surface, the other side of the second cutting blade is connected with a second rear knife face, and a knife point is arranged at a position where the first cutting blade is connected with the second cutting blade. The ball-end mill is used for milling the curved surface splicing molds.

Owner:HARBIN UNIV OF SCI & TECH

Machining process of roller carrier shaft of belt conveyer

InactiveCN104339130AGood plasticity and toughnessGood welding performanceRollersEngineeringMachining process

The invention discloses a machining process of a roller carrier shaft of a belt conveyer, and relates to the field of mechanical manufacturing of conveyers. The machining process comprises the following steps: (1) feeding a blank; (2) milling the end face and punching a center hole; (3) roughly and finely turning the excircle and chamfering; (4) milling a shaft and flattening a groove; (5) grinding the excircle; and (6) relieving stress to anneal. According to the machining process of the roller carrier shaft, the manufacturing precision and strength of the roller carrier shaft are improved through controlling the parameters of the machining procedures of the roller carrier shaft. Moreover, stress relief annealing is finally used in the procedures of the roller carrier shaft to relive the stress in the roller carrier shaft machining procedure. A procedure centralizing principle is used, so that the target can be realized and the cost can be reduced at the same time.

Owner:ANHUI CHANGCHENG TRANSPORTATION MACHINERY MFG

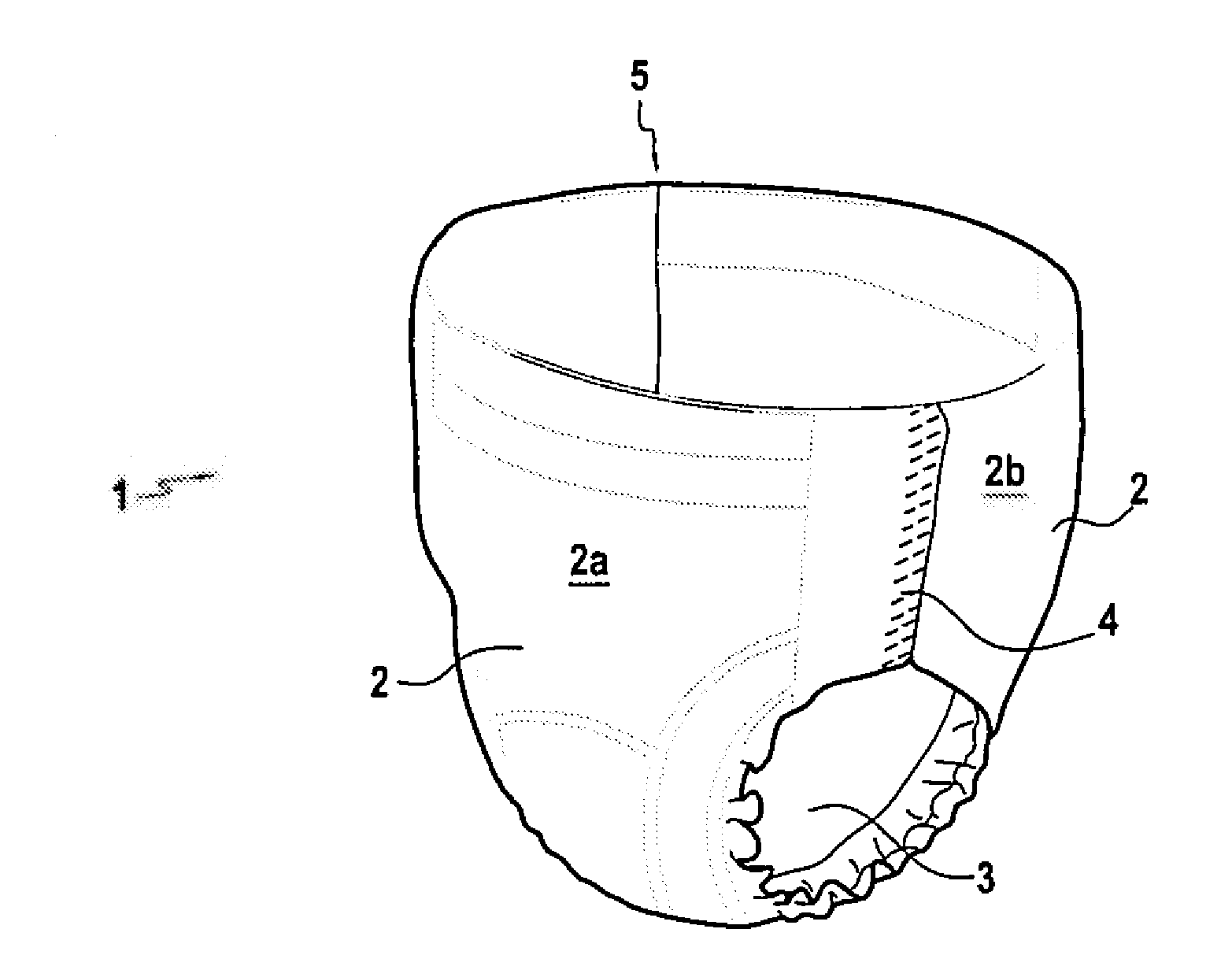

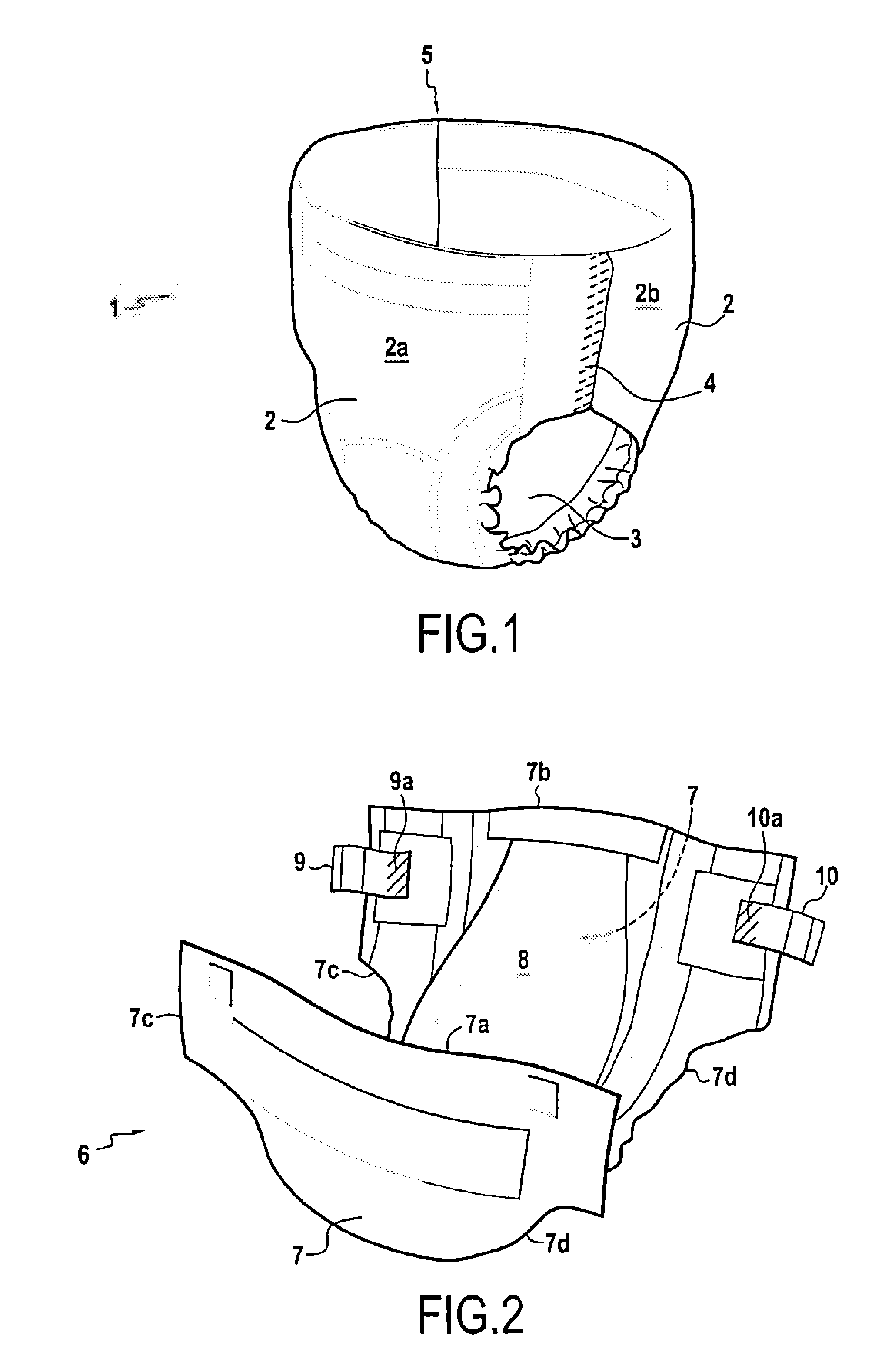

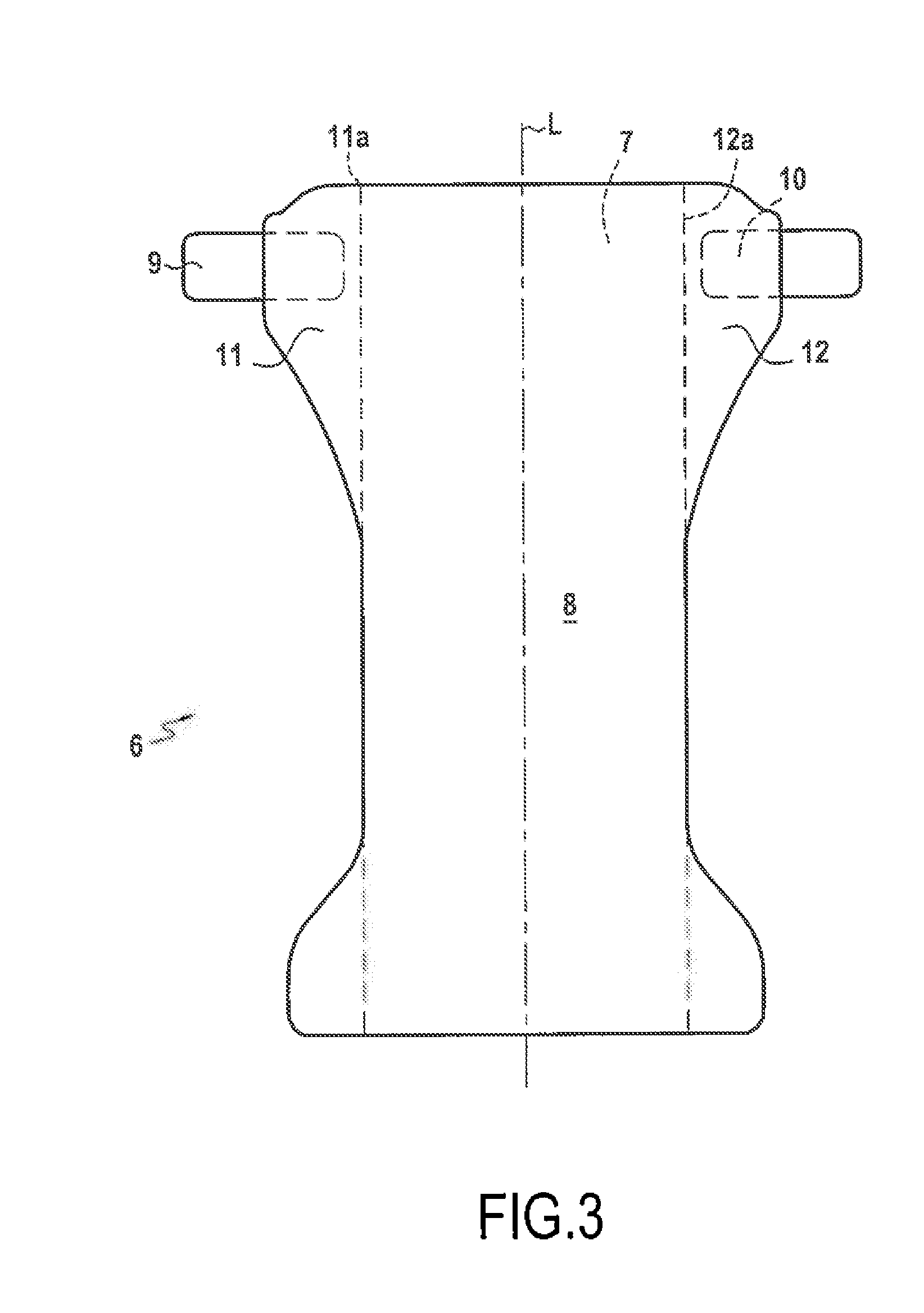

Non-woven of spunbonded thermoplastic filaments having improved weldability properties and method for manufacturing such a non-woven

PendingUS20140135725A1Improve propertiesAvoid Surface Quality IssuesFilament/thread formingBaby linensPolymer scienceThermoplastic elastomer

The object of the present disclosure is a non-woven of spunbonded thermoplastic filaments comprising in a characteristic way, at least 95% by mass (g) of its surface mass (g / m2) of at least two polypropylene A and B polymers, said filaments having a titer of less than or equal to 1.3 dtex, said non-woven having a surface mass of less than or equal to 35 g / m2, the welding rate being at least 10% and at most 25% and at least 88% by mass (g) of its surface mass (g / m2) of said polypropylene A polymer obtained by polymerization in the presence of at least one polymerization catalyst based on a metallocene and at most 12% by mass (g) of its surface mass of said polypropylene B polymer.

Owner:DOUNOR

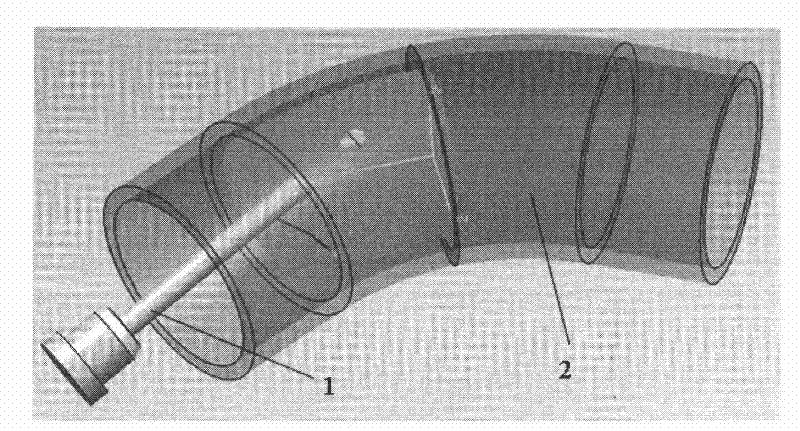

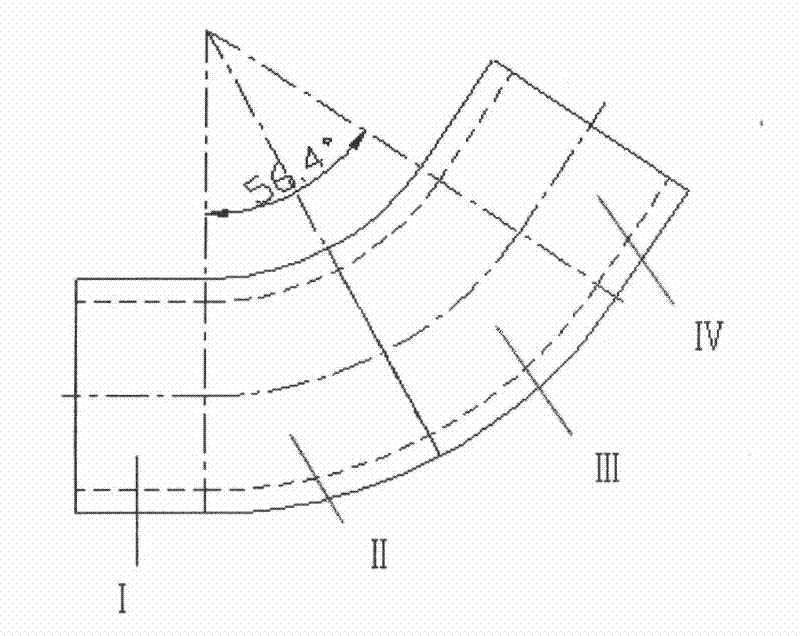

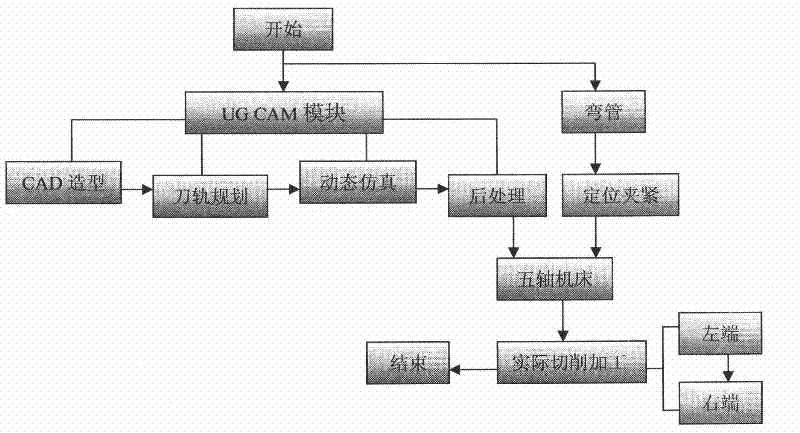

Five-axis NC (numerical control) milling method for internal surfaces of bent pipes

InactiveCN102166665BEnsure delivery accuracyAvoid interferenceMilling equipment detailsSpecial data processing applicationsNumerical controlInterference problem

Owner:DALIAN UNIV OF TECH

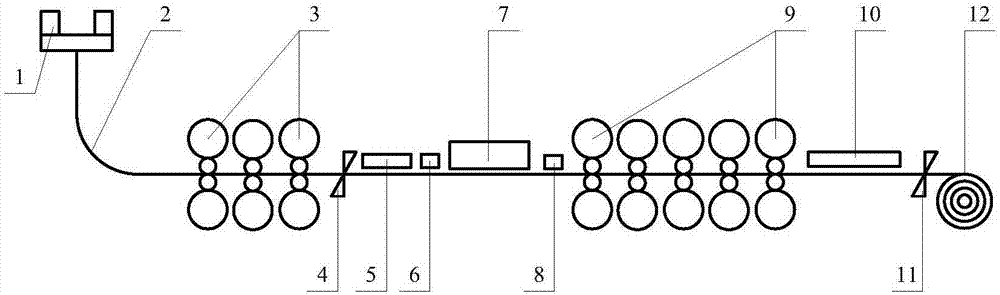

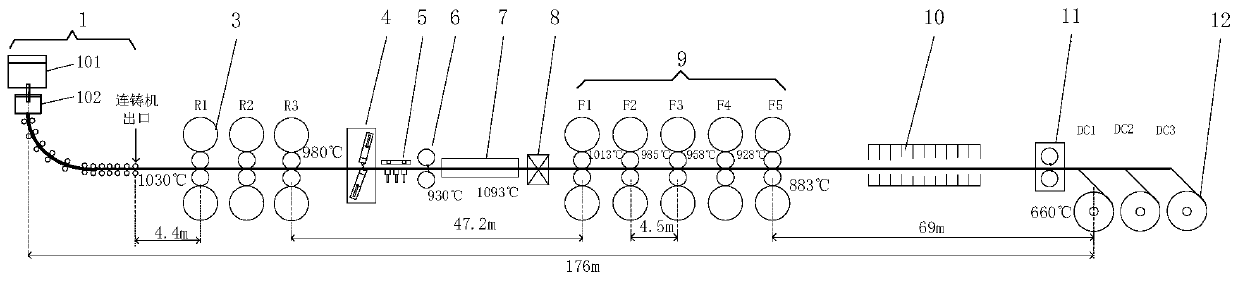

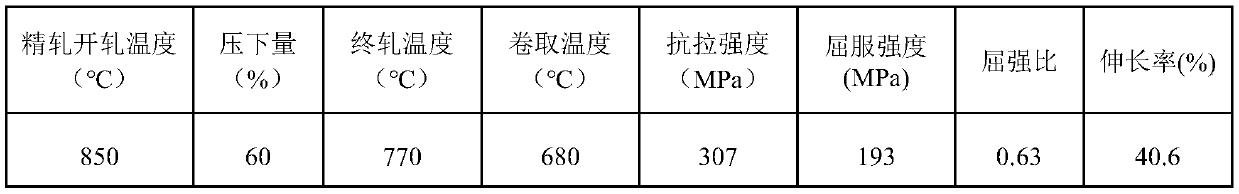

Low-yield-ratio thin strip steel continuous casting and continuous rolling production line and production process

ActiveCN111589865ALengthen the distanceAvoid Surface Quality IssuesMetal rolling arrangementsProduction lineHigh pressure water

The invention belongs to the technical field of steel continuous casting and continuous rolling, and particularly discloses a low-yield-ratio thin strip steel continuous casting and continuous rollingproduction line and a production process. The production line comprises a continuous casting machine, a high-pressure water rough descaling device, a rough rolling unit, a swing shear, a waste blankpushing and stacking device, an emergency shear, an induction heating furnace, a high-pressure water fine descaling device, a finishing rolling unit, a high-speed flying shear and a coiling unit whichare sequentially arranged in the rolling direction. The production process comprises the steps of continuous casting blank forming, high-pressure water rough descaling, rough rolling, induction heating, high-pressure water fine descaling, finish rolling, high-speed flying shear coil dividing and coiling. According to the low-yield-ratio thin strip steel continuous casting and continuous rolling production line and the production process, by additionally arranging rough descaling, reducing the number of induction heating sets, lengthening the distance between finish rolling middle racks and shortening the distance between a finish rolling tail rack and a recoiling machine, production of thin strip steel with high surface quality and low yield ratio is achieved; and meanwhile, due to the fact that rolling line equipment is reduced and the length of the production line is shortened, the construction and operation investment cost of the production line can be reduced.

Owner:CISDI ENG CO LTD +1

Drip-feed type gas boriding process

InactiveCN1952216AUniform penetrationGood surface qualitySolid state diffusion coatingHeat treatment process controlAutomatic controlBoron atom

This invention involves a drip gas boronizing approach. The method contains the steps of: adopting ordinary drip gas carburizing furnace, heating the furnace to the temperature for boronizing, and dropping boriding agent containing trimethyl borate, methanol and chloridated rare earth and methanol to the furnace, decomposing and to form boride on the steel surface through adsorption and diffusion of boron atom decomposed by trimethyl borate. The invention has the advantage of uniform and compact leaking layer, good surface quality, Layer depth and surface boron content can be controlled; no need of cleaning workpiece after infiltration, with directly quenching after infiltration and low labor intensity; penetration enhancers without rank poison, non-explosive, with relatively good and safe, reliable working environment, without specialized equipments, commonly used carburizing furnace can meet the requirements, can handle all sorts of shapes and sizes workpiece, can be easy to achieve automatic control, with high efficiency, easy operation and high applicability.

Owner:JIANGSU UNIV

Production method of synthetic grinding fluid for metallurgy roller

InactiveCN103627502AImprove the lubrication effectImprove adsorption capacityLubricant compositionPolyethylene glycolSebacic acid

The invention provides a production method of a synthetic grinding fluid for a metallurgy roller. The production method comprises the following steps that 1, oleic acid and triethanolamine undergo a reaction in a reactor; the reaction system is stirred continuously at a rotation rate of 100r / min; the reaction system is heated to a temperature of 50-60 DEG C; and the reaction system is stirred sequentially for 30min for next use; 2, deionized water, sebacic acid and triethanolamine are orderly added into a reactor; a stirrer is started; and the mixture is stirred at a rotation rate of 100r / min for 1h; 3, sodium benzoate, polyether, polyethylene glycol, sodium carbonate, ammonium molybdate, glycerin, benzotriazole, an antifoaming agent, isothiazolinone, fluorescent green and triethanolamine oleate obtained by the step 1 are orderly added into the reactor used in the step 2; the reaction system is heated to a temperature of 50-60 DEG C; and the reaction system is sequentially stirred for 1h; and 4, the reaction product is cooled to a normal temperature to form the synthetic grinding fluid. The synthetic grinding fluid obtained by the production method has excellent lubrication, cooling, cleaning and rust resistance functions.

Owner:TIANJIN INTELLECT SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com