Manufacturing method of secondary-cold-rolling shadow mask strip steel in thin specification

A technology of secondary cold rolling and manufacturing method, which is applied in the field of manufacturing ultra-low carbon thin-gauge shadow mask strip steel, which can solve the problems of high continuous annealing temperature and increased defects of strip steel materials, so as to reduce continuous annealing temperature and reduce fracture The effect of bringing probability and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1-10

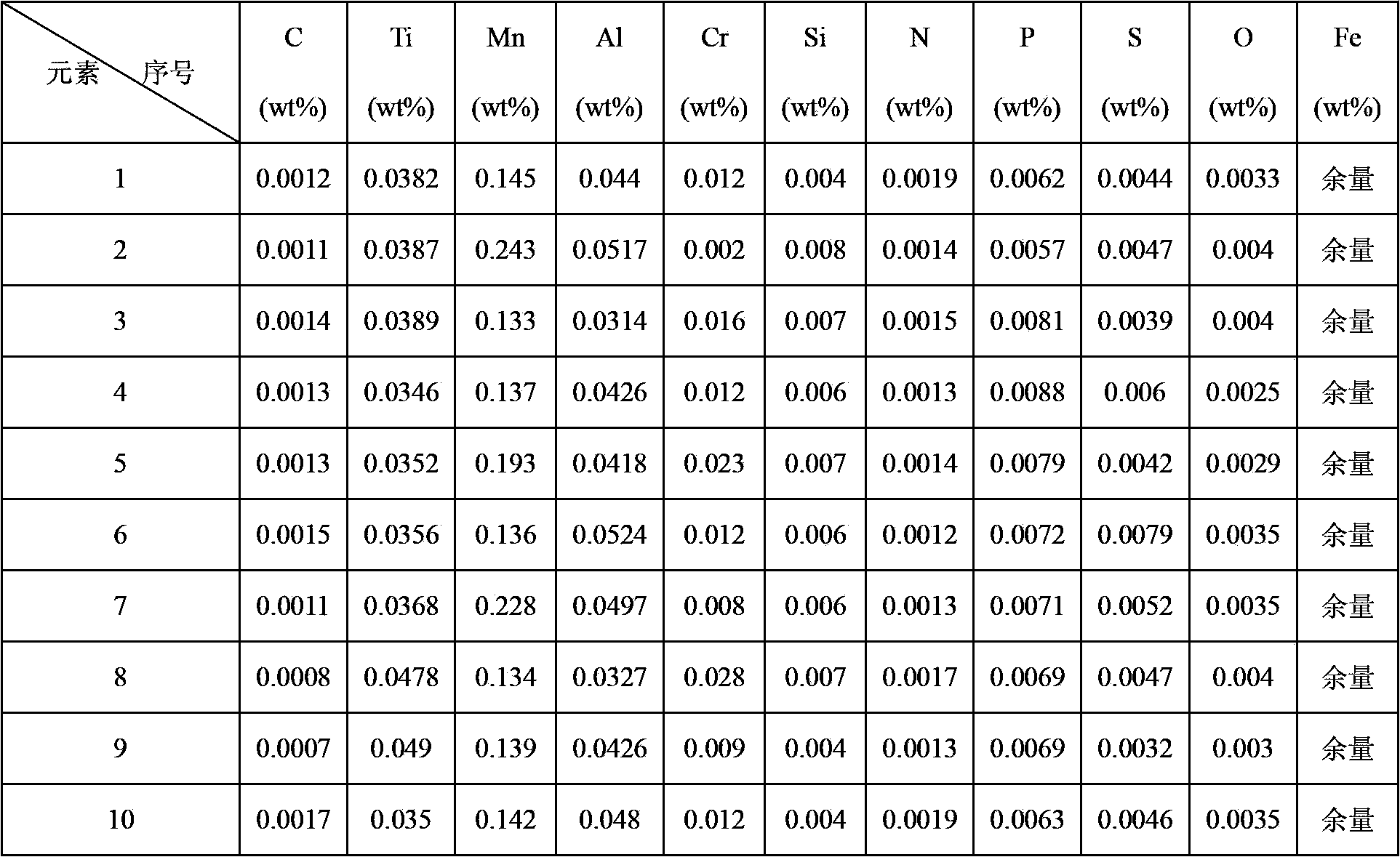

[0048] Table one embodiment chemical composition (mass percentage composition, wt%)

[0049]

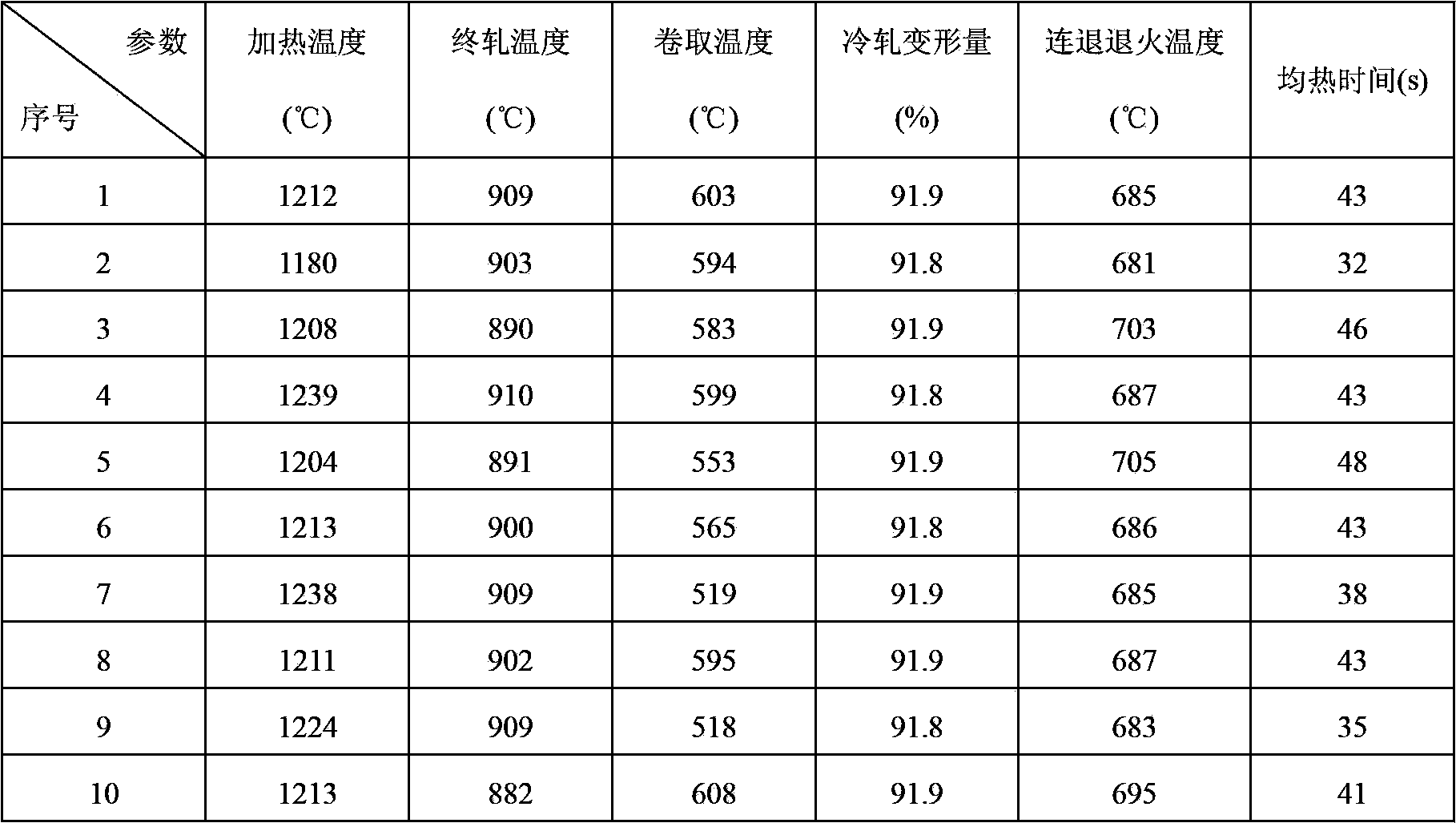

[0050] Table 2 Hot rolling, cold rolling and continuous annealing process parameters

[0051]

[0052] Table 3 Processing parameters of secondary cold rolling process

[0053]

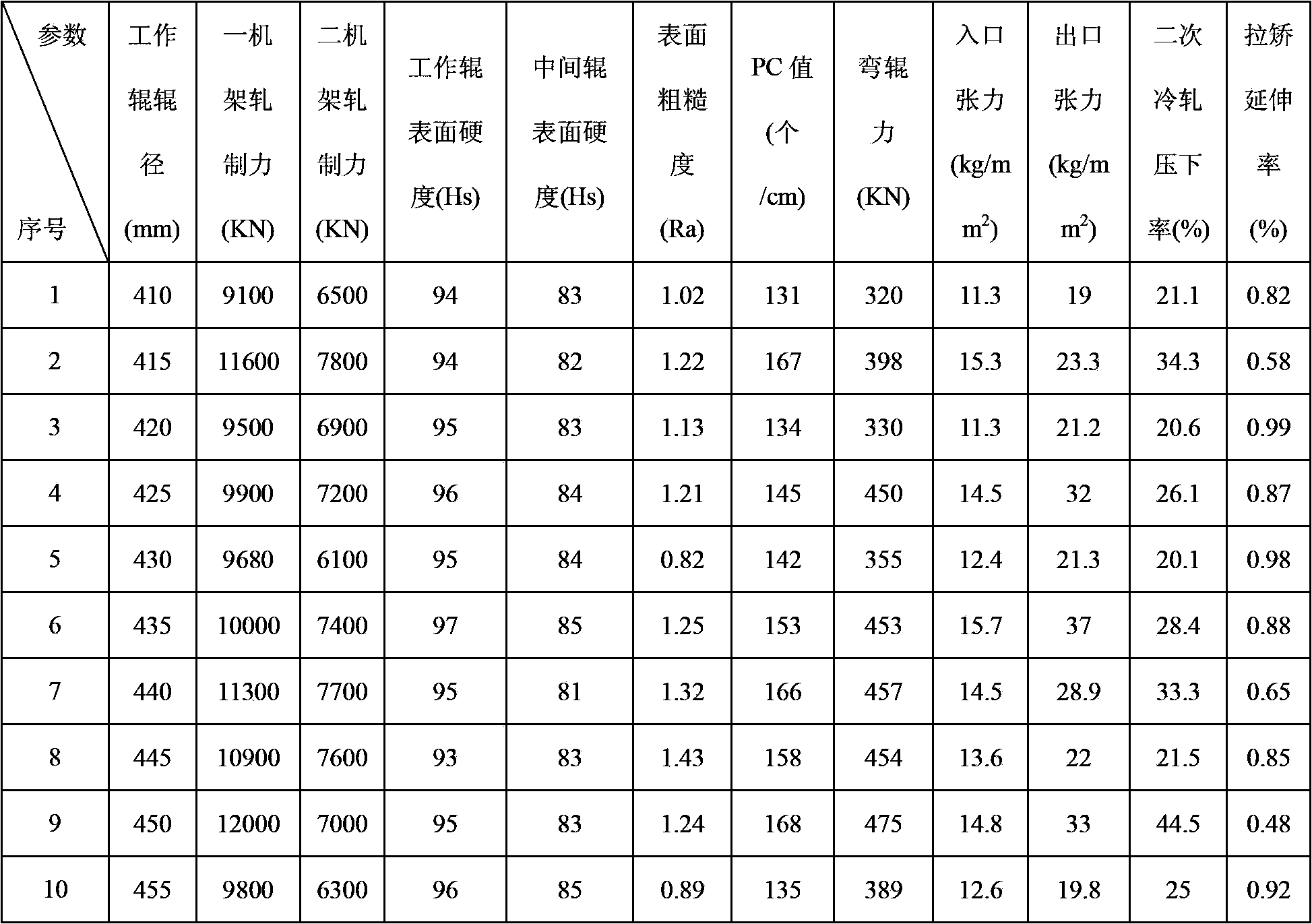

[0054] Table 4 Performance parameters of secondary cold-rolled shadow mask strip products

[0055]

[0056] According to the results of 1-10 specific examples, it can be seen that the qualified product is finally obtained, the thickness is about 0.15mm, the yield strength is 412~498Mpa, the tensile strength is 514~581Mpa, the elongation is 3~7%, and the strip material surface roughness Ra is 0.38~0.62μm, Rz is 2.55~2.82μm, Rsm is 84.4~105.7μm, Rsk is 0.76~1.03, HV is 148~178, all waves are less than 2.8mm. It can be seen that the various properties and surface quality parameters of the product obtained by the present invention can well meet the requirements of subsequent processing procedures su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com