Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

A duplex stainless steel, surface crack technology, applied in workpiece surface treatment equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of steel plate surface cracks and edge cracks, low rolling temperature, and many rolling passes. The effect of reducing scrap rate, shortening rolling time and reducing temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to technique of the present invention, carry out the method for plate rolling of duplex stainless steel 2205:

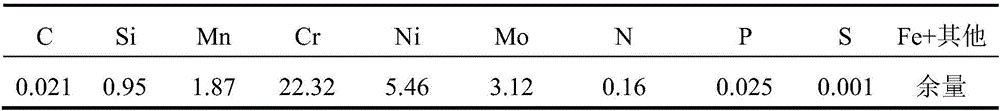

[0029]

[0030] (1) Blank selection and grinding

[0031] The specifications of the 2205 duplex stainless steel billet are: thickness × width × length = 160mm × 1238mm × 1800mm. A 30-mesh grinding wheel was used to fully grind the slab, and the grinding rate was 1.8%. After grinding, the surface of the slab had no visible defects with the naked eye, and the surface roughness was Ra=56 μm.

[0032] (2) billet heating

[0033] The ground slab is sent to the walking heating furnace for heating, and the slab is released from the furnace after passing through the preheating section, heating section and soaking section in sequence. The temperature in the preheating section is 1110-1140°C, the temperature in the heating section is 1160-1230°C, the temperature in the soaking section is 1230°C, and the dwell time is 160 minutes.

[0034] (3) High pressu...

Embodiment 2

[0043] According to technique of the present invention, carry out the method for plate rolling of duplex stainless steel 2205:

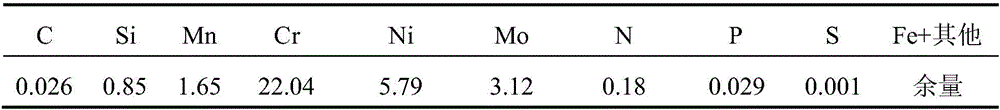

[0044]

[0045] (1) Blank selection and grinding

[0046] The specifications of the 2205 duplex stainless steel billet are: thickness × width × length = 180mm × 1550mm × 2500mm. A 30-mesh grinding wheel was used to fully grind the slab, and the grinding rate was 2.1%. After grinding, the surface of the slab had no visible defects with the naked eye, and the surface roughness was Ra=58 μm.

[0047] (2) billet heating

[0048] The ground slab is sent to the walking heating furnace for heating, and the slab is released from the furnace after passing through the preheating section, heating section and soaking section in sequence. The temperature in the preheating section is 1120-1150°C, the temperature in the heating section is 1180-1240°C, the temperature in the soaking section is 1235°C, and the dwell time is 180 minutes.

[0049] (3) High pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com