A method for reducing the residual stress of steel rail and the obtained steel rail and its application

A residual stress and rail technology, applied in the direction of rail, rail, process efficiency improvement, etc., can solve the problems of insufficient flatness and surface quality, and high residual stress of rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

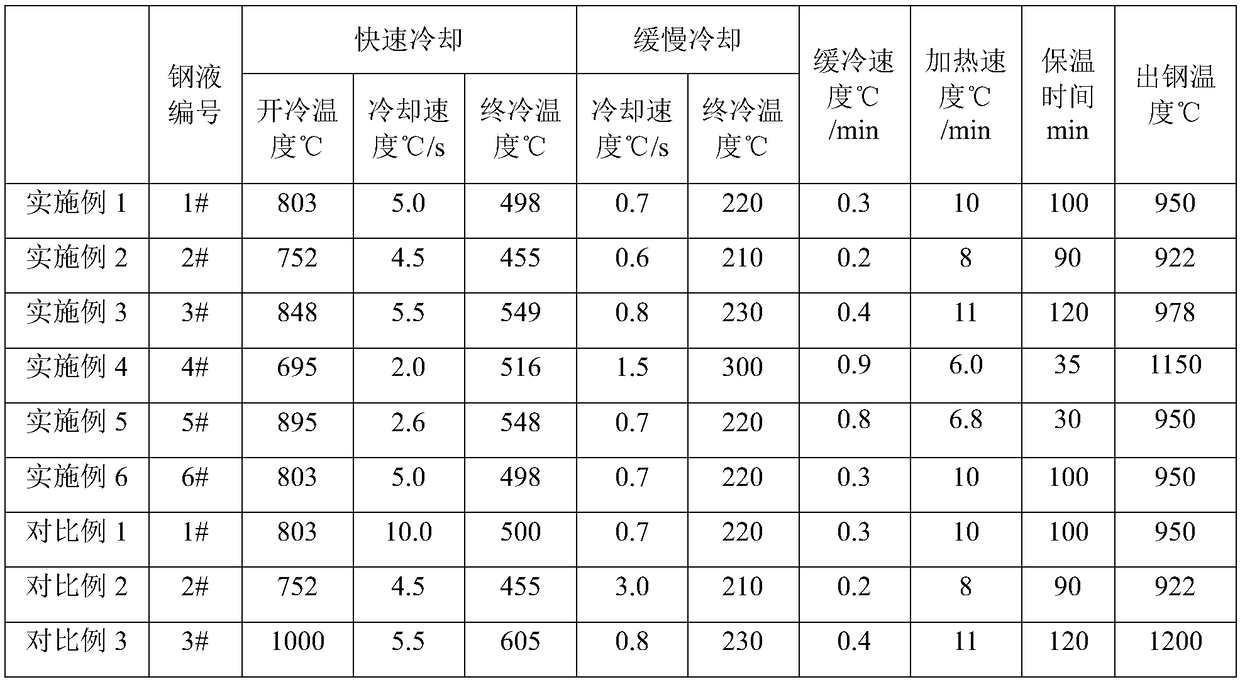

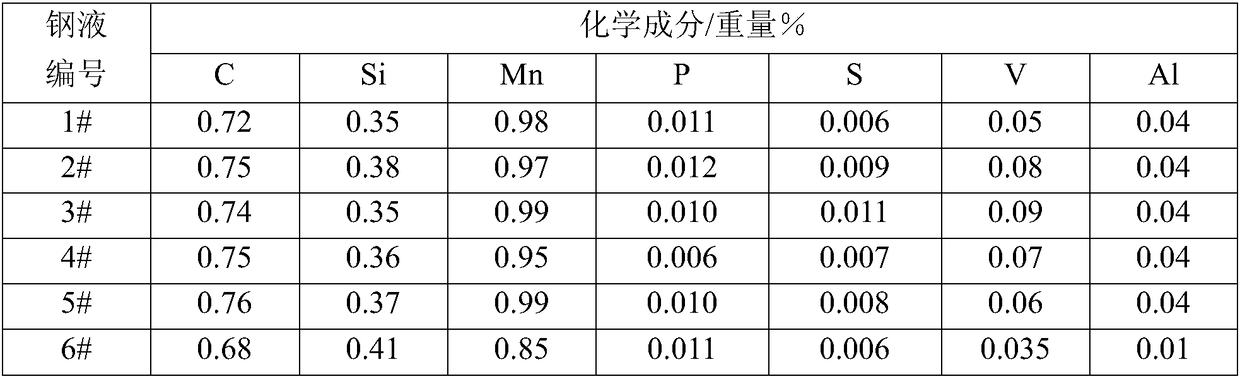

[0031] (1) Molten steel smelting: Smelting is carried out with low-S furnace molten iron with an S content of about 0.008% by weight. During the smelting process, refining slag composed of aluminum oxide, barium oxide and calcium fluoride (wherein the percentage content is w(Al 2 o 3 )=23% by weight, w(BaO)=10% by weight, w(CaF 2 )=5% by weight, the basicity is 5) and a carburant composed of anthracite and low-N alloy, a foaming agent is used in the heating process of the LF furnace, and the composition content is controlled to finally obtain the chemical compound shown in 1# in Table 1 Composition of molten steel.

[0032] (2) The molten steel obtained in step (1) is fully protected and cast into a steel billet, and then sent to the slow cooling pit for slow cooling at a rate of 0.3°C / min, and the steel billet cooled to room temperature is sent into a heating furnace for heating and heat preservation ( The heating rate is 10°C / min, the termination temperature (tapping temp...

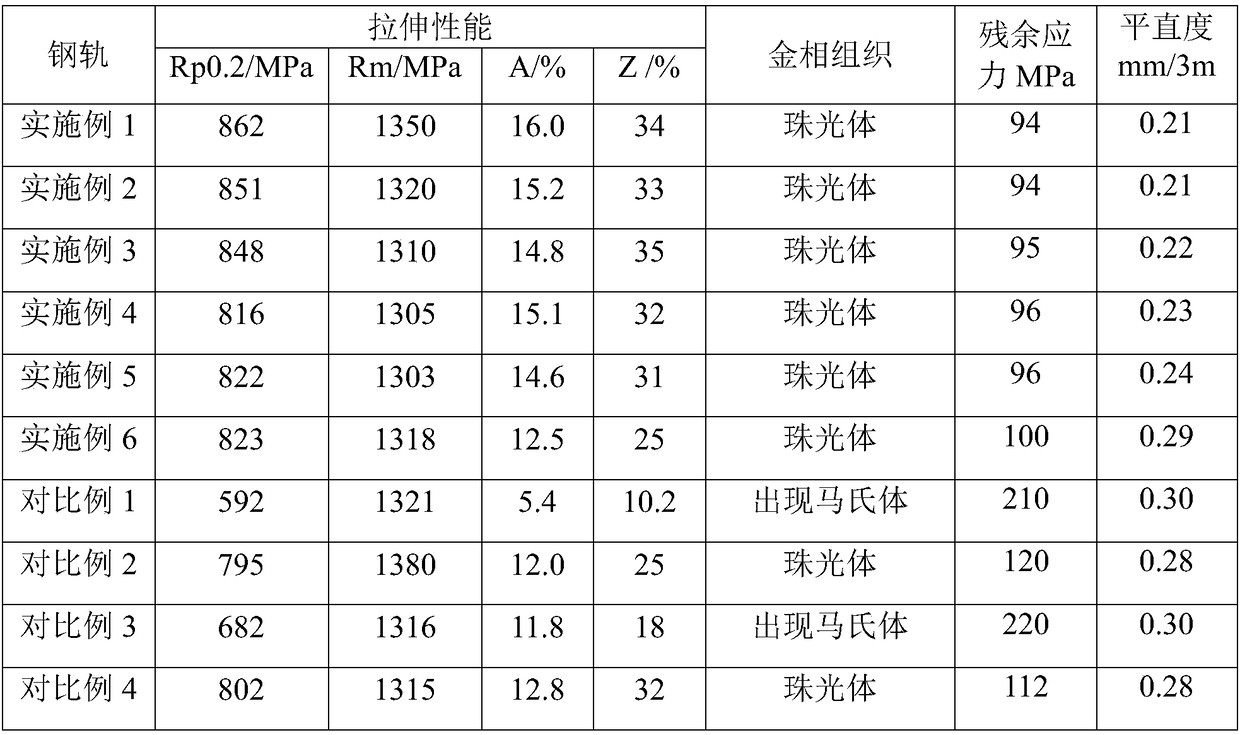

Embodiment 2-6

[0035] According to the method of Example 1, the difference is that the chemical composition of the molten steel obtained by smelting is as shown in Table 1 and Table 2, and the specific operating parameters of the method are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com