Laser induced low pressure jet flow combined etching processing method and device

A technology of laser induction and processing equipment, which is applied in the field of combined processing using laser etching, special processing equipment for this method, water jet processing and chemical corrosion, which can solve the problem that the processing speed cannot meet the requirements, affect the quality of the etched surface, and have no It solves the surface quality problems of micro-cracks and other problems very well, and achieves the effect of good surface processing quality, reducing temperature gradient and avoiding micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019]Embodiment 1: This embodiment is a laser-induced low-pressure jet composite etching processing method. First, a high-energy-density laser beam is used to etch the workpiece, and at the same time, a certain pressure of the corrosive medium solution is used to wash away the slag on the laser processing surface. and corrosion, reducing the roughness of the machined surface. The liquid medium has a cooling effect during processing, and can also reduce the temperature gradient of the processing surface, avoiding microcracks on the processing surface of hard and brittle materials due to thermal stress.

[0020] The corrosion solution is HCl solution or KOH solution, the concentration of HCl solution is 65%; the concentration of KOH solution is 75%, one of them is selected according to the material of the workpiece, and the concentration can be diluted.

Embodiment 2

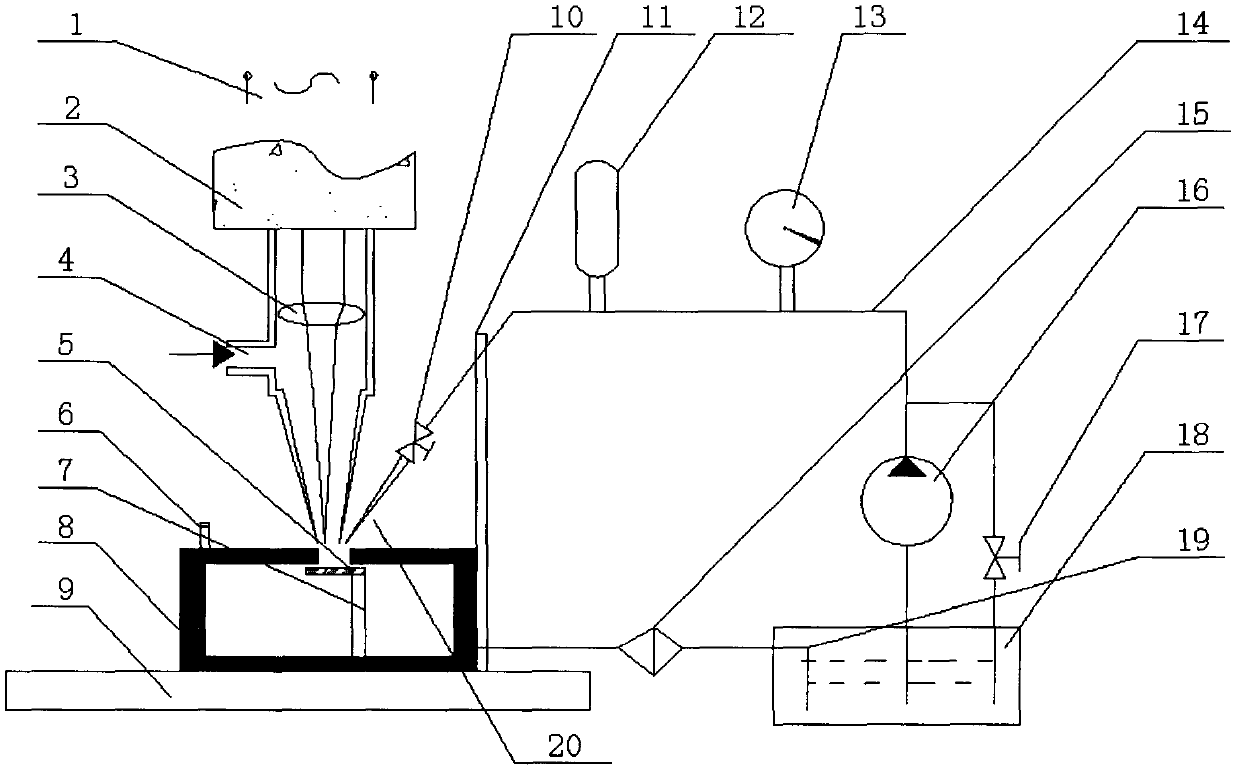

[0021] Embodiment 2: This embodiment is a laser-induced low-pressure jet composite etching processing device, including an AC power supply 1 and a laser 2, and also includes a focusing lens 3 and an X-Y-Z numerical control workbench 9, and also includes a fluidic device and a workpiece fixture 7, wherein the fluidic device Including corrosive liquid tank 18, plunger high-pressure pump 16, pressure gauge 13, accumulator 12, one-way control valve 10, corrosion-resistant nozzle 20, jet device fixing fixture 11, one end of plunger high-pressure pump 16 is connected to liquid inlet pipe 14 , passes through the pressure gauge 13, flows into the accumulator 12, eliminates the water pressure pulsation, and sprays out through the corrosion-resistant nozzle 20. The fixation and angle change of the corrosion-resistant nozzle are completed by the fixing fixture of the jet device.

[0022] This example also includes a corrosive liquid circulation filtration and return system, which includes...

Embodiment 3

[0025] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, and the power supply 1 is a three-phase AC power supply.

[0026] When the device of embodiment 2 and embodiment 3 is working, the sealed work box 8 is fixed on the X-Y-Z numerical control workbench 9, the workpiece 5 is fixed on the sealed work box 8 by the workpiece clamp 7, and the X-Y-Z numerical control workbench 9 is controlled by computer according to the regulations. The trajectory movement can ensure that there is relative movement between the workpiece 5 and the laser beam and the jet beam, so that any etching process can be performed. The laser 2 is used for processing, and the relatively high laser energy density is used to directly act on the surface of the workpiece 5 to be etched. Melting, vaporization and jetting occur at the laser action point on the surface of the workpiece 5, thereby forming holes, and then within a short time Almost synchronously with the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com