Method for recovering 99.98% copper powder from etching liquid and preparing 99.999% cathode copper

A cathode copper and etching solution technology, applied in the improvement of process efficiency, photography process, instruments and other directions, can solve the problems of difficult to deal with pollutants, long pyrometallurgical process, small processing profit, etc., to improve surface quality, equipment, etc. Small, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

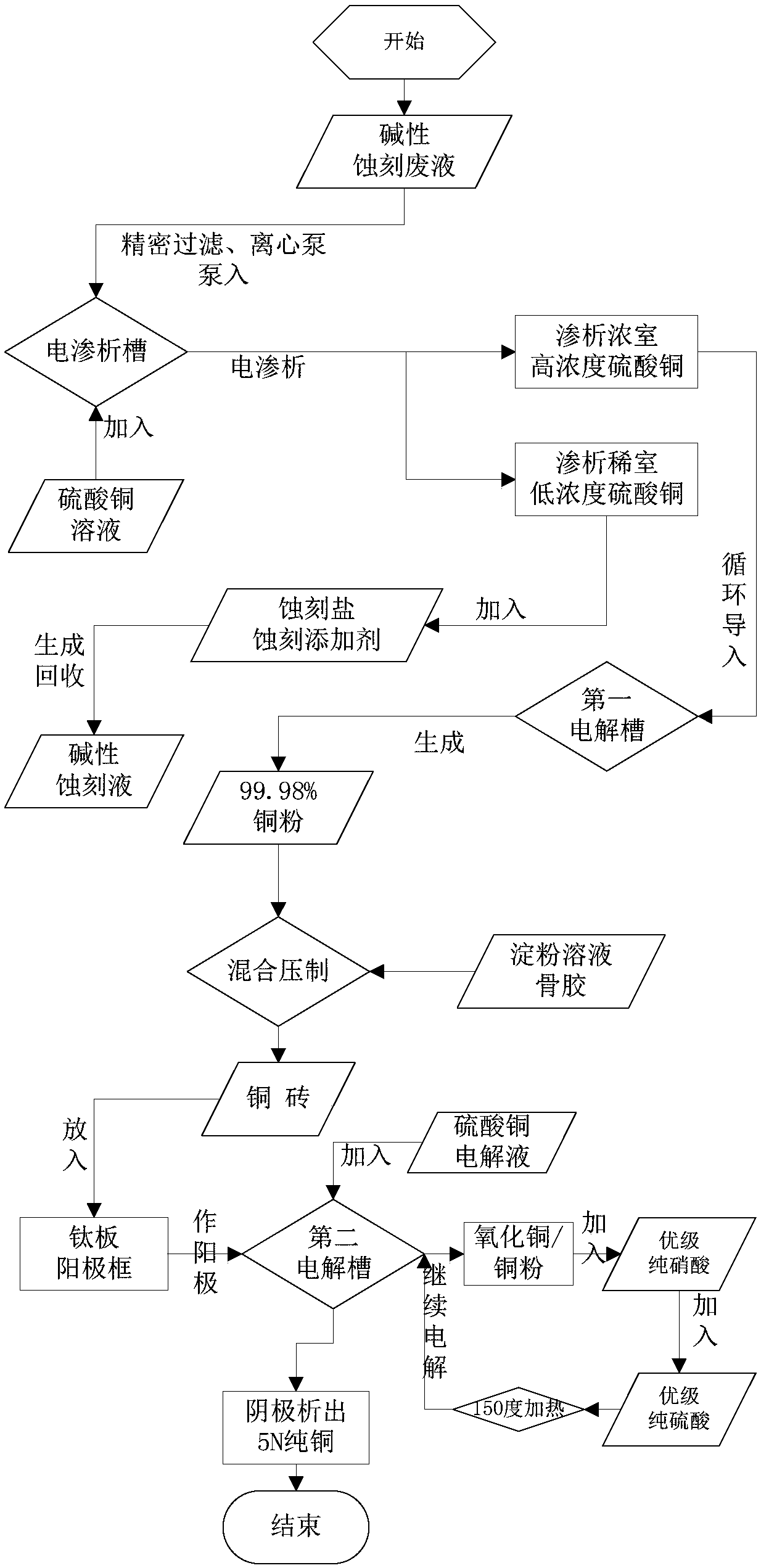

[0029] Such as figure 1 shown. In the flow process of the whole method, the initial treatment object is alkaline etching waste liquid. First, the alkaline etching waste liquid is added to the electrodialysis tank with copper sulfate solution as the electrodialysis solution. A large amount of copper ions will accumulate in the concentrated chamber. Then this part of the solution in the concentrated chamber is introduced into the electrolytic tank for electrolysis, and the copper powder with a purity of 99.98% can be obtained. These copper powders are taken out from the electrolytic tank in sequence, washed, filtered, and dried, then mixed with bone glue and starch solution and copper powder, and pressed into copper bricks. Then put the copper brick into the anode frame made of titanium material, and continue to carry out electrolytic refining in the electrolytic tank, and then the copper with a purity of 99.999% can be obtained at the cathode of the electrolytic tank.

[003...

Embodiment 2

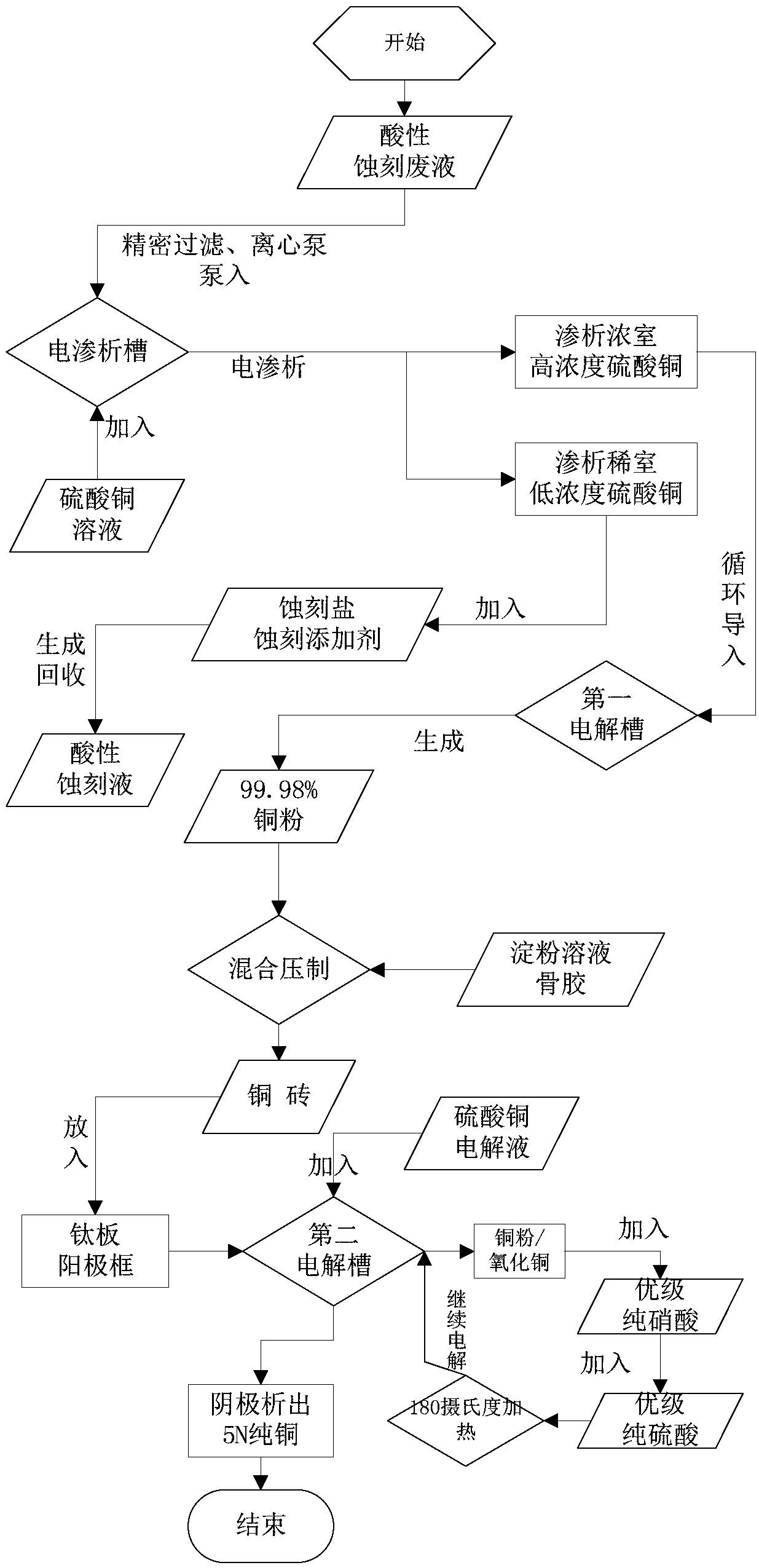

[0046] Such as figure 2 shown. In the process of the whole method, the initial treatment object is acidic etching waste liquid. Firstly, the acidic etching waste liquid is added to the electrodialysis tank with copper sulfate solution as the electrodialysis solution. A large amount of copper ions will accumulate. Then this part of the solution in the concentrated chamber is introduced into the electrolytic tank for electrolysis, and the copper powder with a purity of 99.98% can be obtained. These copper powders are taken out from the electrolytic tank in sequence, washed, filtered, and dried, then mixed with bone glue and starch solution and copper powder, and pressed into copper bricks. Then put the copper brick into the anode frame made of titanium material, and continue to carry out electrolytic refining in the electrolytic tank, and then the copper with a purity of 99.9995% can be obtained at the cathode of the electrolytic tank.

[0047] The specific process is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com