Resetting device using flexible positioning and rigid clamping in combination and positioning method thereof

A repeat positioning and flexible positioning technology, applied in positioning devices, clamping, support and other directions, can solve the problems of difficult to use large and small parts, high installation requirements of combined devices, difficult to guarantee accuracy, etc., to eliminate human accumulated errors and improve Product accuracy and consistency, the effect of high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

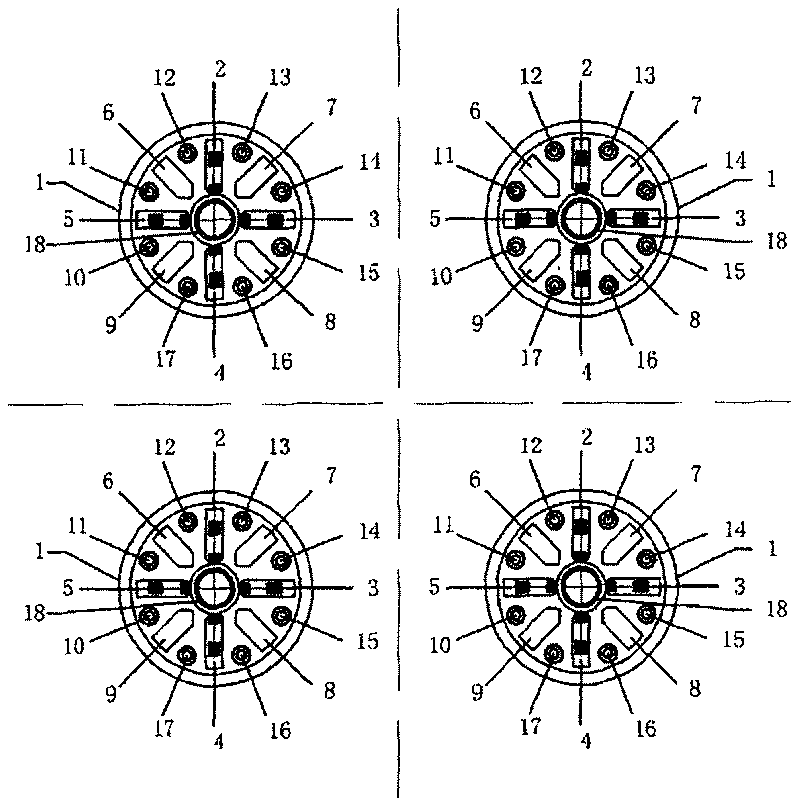

[0037] figure 1 It is a schematic structural diagram of a chuck set according to an embodiment of the present invention. As shown in the figure, in this embodiment, four circular chucks 1 are arranged on the table, and a nail hole 18 is arranged in the center of each chuck, and four positioning teeth 2 arranged radially are arranged around the nail hole. , 3, 4, 5, the 4 positioning teeth are evenly distributed on the top surface of the chuck, the middle part of the side of the positioning tooth is provided with a positioning slope, and the two adjacent positioning teeth are provided with bosses 6, 7, 8, 9 , The surface of the boss is a Z-direction stop plane, and the Z-direction stop plane is parallel to the top surface of the chuck. Eight mounting screw holes 10-17 are arranged on the edge of the chuck to facilitate the installation of the chuck on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com